We provided the client with a device and system they were able to reliably use in their research as they designed a compact micropump controller and supporting application to assist in their research and testing. The solution included features such as a Nordic Bluetooth Module for communicating with a Python based PC application for data logging and control as well as for over-the-air firmware updates. The system also included a wireless Qi charging system, a high voltage pump driver and flow monitor, and a fuel gauge sensor. The fuel gauge sensor was used to determine the battery health and charge levels. DMC focused on fully supporting these sensors with the firmware and PC application.

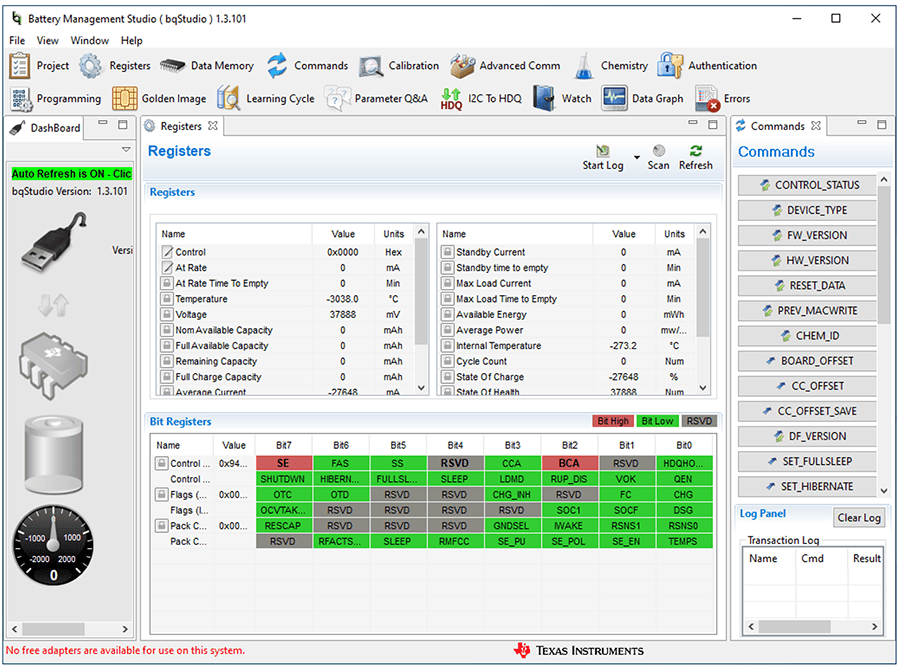

For the customer to accurately monitor the state of charge remotely, DMC integrated a fuel gauge into the device, transmitted its status via Bluetooth, and created a manufacturing process to commission each unit during assembly. DMC wrote a custom I2C driver for a TI fuel gauge sensor utilizing Texas Instrument’s Impedance Track (TM) Based Fuel Gauging. To accurately determine the battery status, a series of tests were performed to profile the battery pack and determine the battery chemistry. This battery chemistry ID was used by the fuel gauge to accurately determine the state of charge of the battery pack compensating for self-discharging as well as battery aging. During manufacturing, each fuel gauge was programmed and calibrated using TI’s Battery Management Studio (bqStudio).

Texas Instrument’s Battery Management Studio used to program and calibrate the fuel gauge devices.

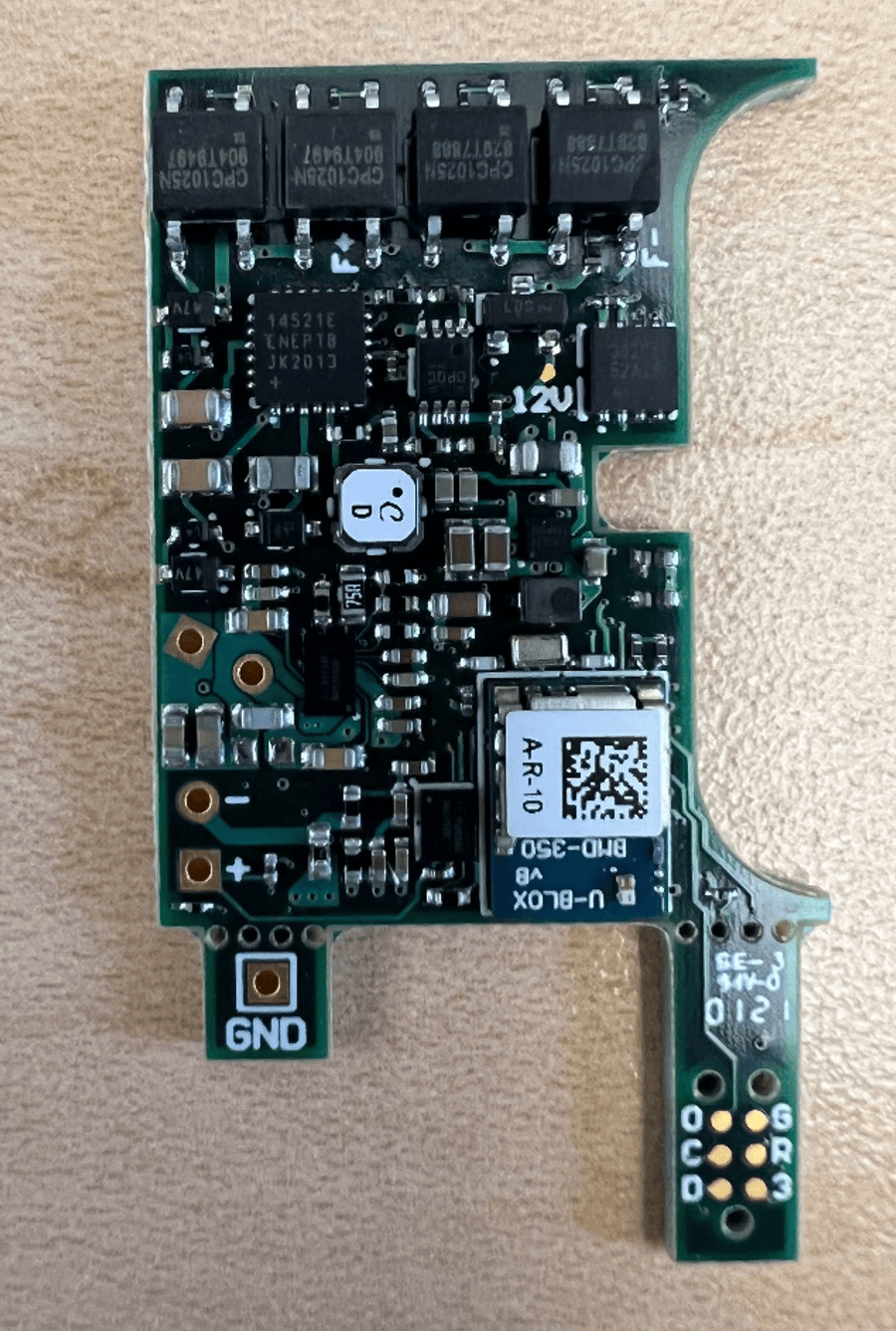

DMC helped the customer solidify their hardware design for manufacturability and consistency. DMC used reverse engineering to recover their existing design files. DMC applied our best practices for printed circuit board (PCB) design to improve the client’s latest revision of the device; so, it could be utilized in their research. This additionally included updating and modifying the Python based PC application to support plotting and report generation to be able to properly evaluate the performance of the prototype system.

Image of redesigned PCB prior to final assembly and calibration.

In the end, we leveraged our extensive hardware design experience and vast embedded software experience to pick up existing designs and to build upon them — yielding a testable device for our client that is efficient and functional.

Learn more about DMC’s product development expertise and contact us to get started on your next project!