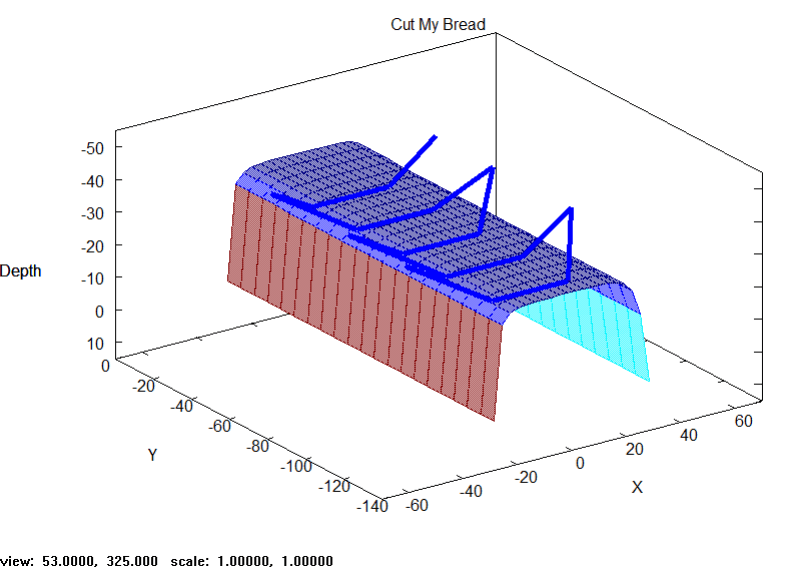

DMC's client had three Fanuc delta robots installed and wired, but the robots needed to be programmed and integrated into their existing automated bread-making system. The robots were programmed using a modified version of "Pick and Place" from PickTool to score dough using ultrasonic knives as end effectors. The robots were integrated into the Beckhoff PLC system and could be controlled via the HMI running Iconics Genesis 32 software.

DMC's client had three Fanuc delta robots installed and wired, but the robots needed to be programmed and integrated into their existing automated bread-making system. The robots were programmed using a modified version of "Pick and Place" from PickTool to score dough using ultrasonic knives as end effectors. The robots were integrated into the Beckhoff PLC system and could be controlled via the HMI running Iconics Genesis 32 software.