A client in the manufacturing industry has an assembly line with several manual assembly stations. The client defined targets for how many units per operator shift are needed for production. They asked DMC to create a solution to track operator performance and record data for line productivity.

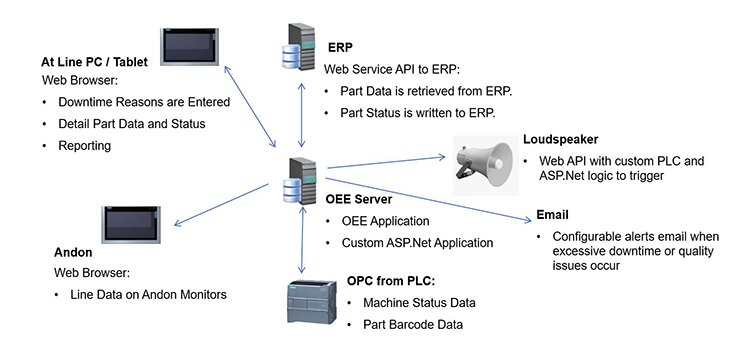

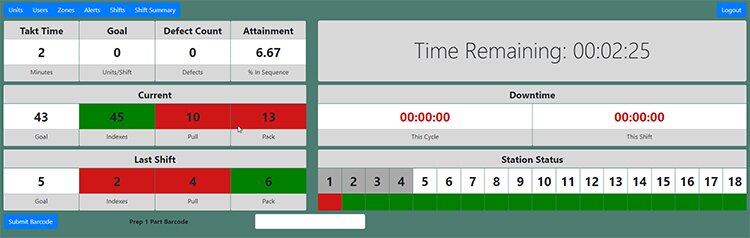

DMC created a custom web application in ASP.NET to collect this operator data and write it to the line PLC. DMC used a Rockwell ControlLogix PLC to aggregate the data and supply it to FactoryTalk Metrics using OMAC PackML standard data structures to simplify configuration. An ASP.NET display takes readings from FactoryTalk Metrics, a local SQL Server database, and the PLC displays them on an Andon screen above the assembly line to display a summary of how the line is running on the shift.

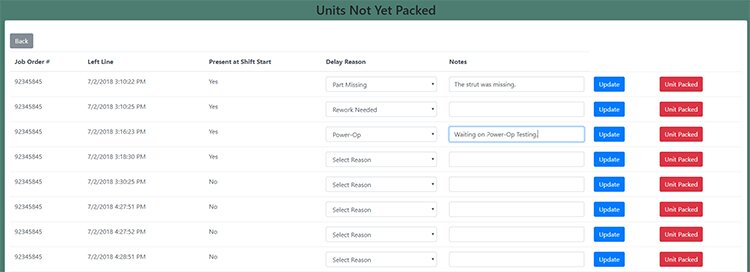

When operators run into issues on the line, they can enter the reason for the hold into the Andon system. FactoryTalk Metrics then compiles the data, developing events and custom reports using SQL Server. The SQL Server uses reporting services for later reporting to drive continuous improvement efforts.

DMC also provided an Alarming solution that sends announcements through the industrial speaker when a serious problem with line productivity is identified. Event-driven emails are sent to notify management of potential issues on the line in real-time.