AIC reached out to DMC for assistance in developing the WinCC portion of the project. DMC is a leading WinCC system integrator, and like AIC, a Siemens Solution Partner. DMC supported side-by-side development with the AIC team by participating in knowledge sharing on the WinCC architecture decisions, as well as by offering advice on efficient program structure and system execution. DMC and AIC used an online collaborative software called Trello to track project status and to divide up tasks. Although the project was large, DMC and AIC were easily able to coordinate and deliver a successful project.

Machine Control

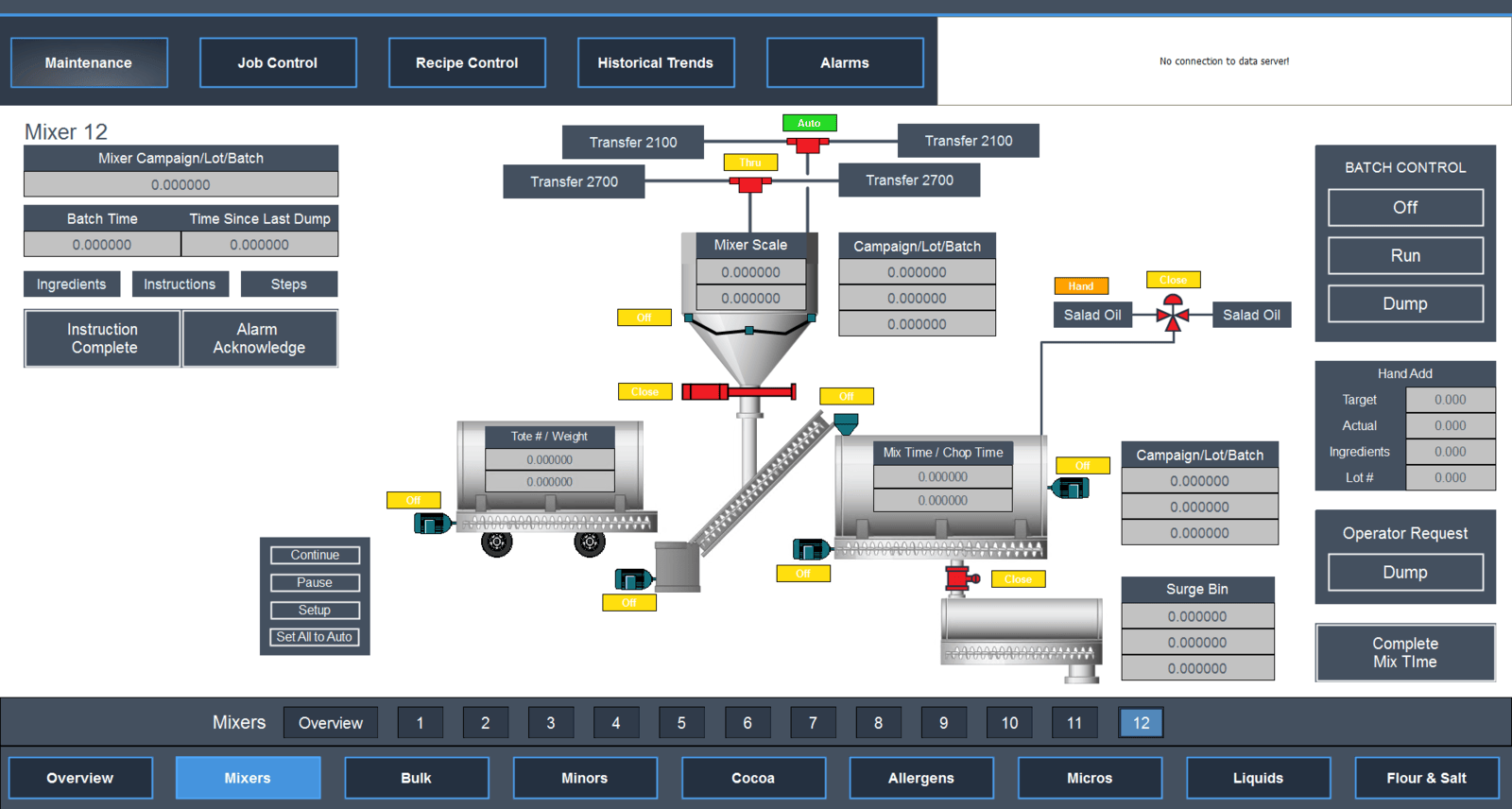

The original system managed more than just recipe/job control. It also included full machine control for all the different pieces of equipment throughout the plant. DMC used our experience in graphic design and UI layout to redevelop the user interface from the ground up, while maintaining the feel of the original feel of the old system. The result is a sleek design that allows for easy navigation across the entire application.

Figure 1 The Mixer Screens allow full control over every valve and motor in the system

Job Control and Recipe Creation

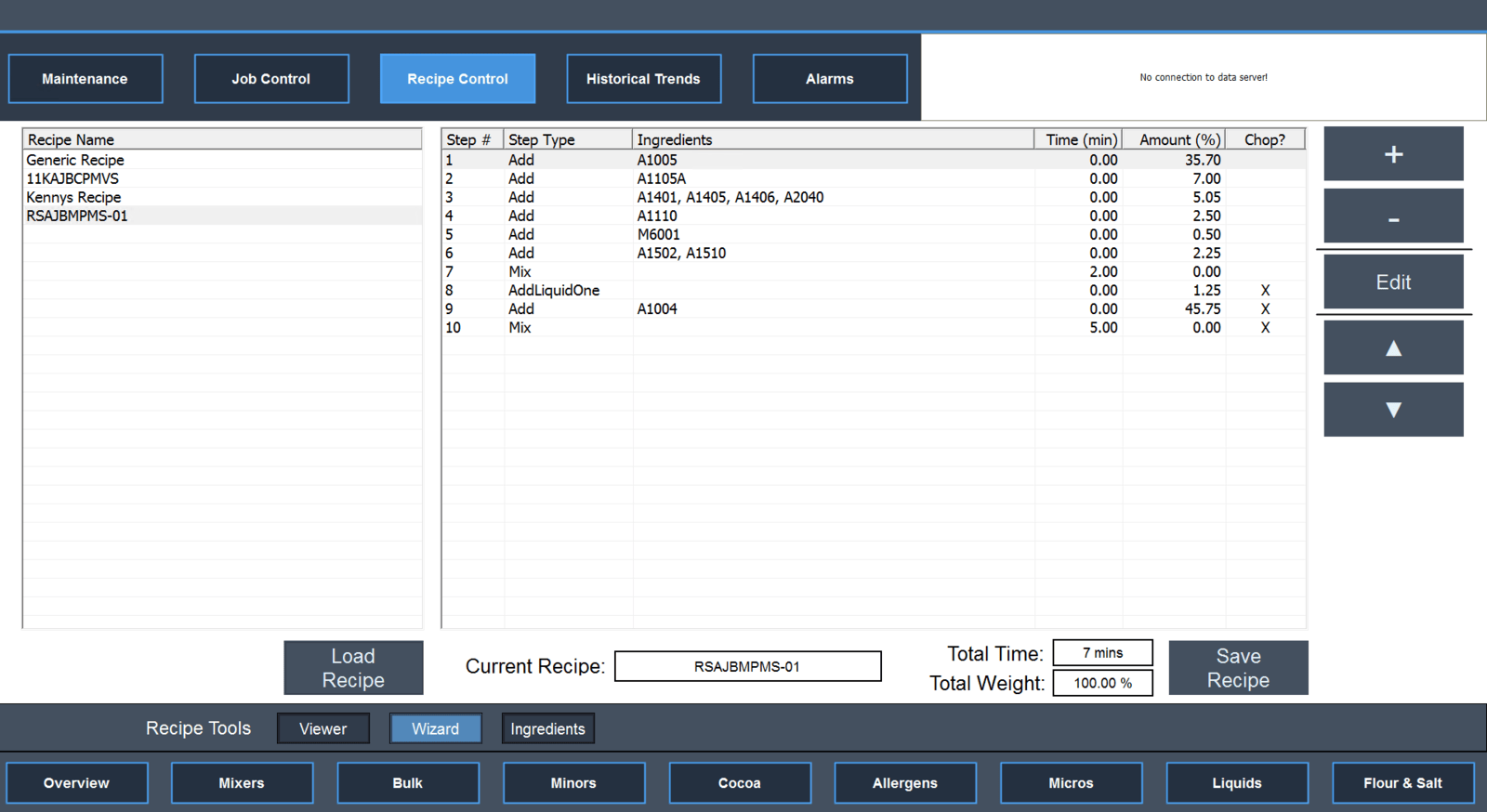

DMC was able to develop a front-end interface to interact with PM-Control. PM-Control offers a flexible parameter control system to allow seamless integration of production orders into any operating system. The front-end interface complemented the back-end recipe creation by allowing operators to queue up recipes on specific machines with ease. The original In-Batch system had a complicated interface that involved sequence diagrams unrequired for the customer’s use case, so the biggest challenge was to design an interface that was easy to understand and easy to use.

A second challenge was to overcome PM-Control's limitations. PM-Control is a fantastic tool to use for job and recipe creation, but unmodified, it lacked the power to give the required process control for a system this complex. To use PM-CONTROL to accomplish the task, DMC developed a wrapper API over PM-CONTROL's available functions extending the out of the box functionality. By doing this, DMC was able to develop a custom process control screen that would take the recipes developed in the PM-CONTROL screens and populate additional recipe data with the proper process steps. This additional recipe data is now sent to the PLC and used to control the entire process of the recipe creation.

Figure 2 The Recipe Wizard Screen allows for an operator to easily customize multiple recipes and construct complex sequences.

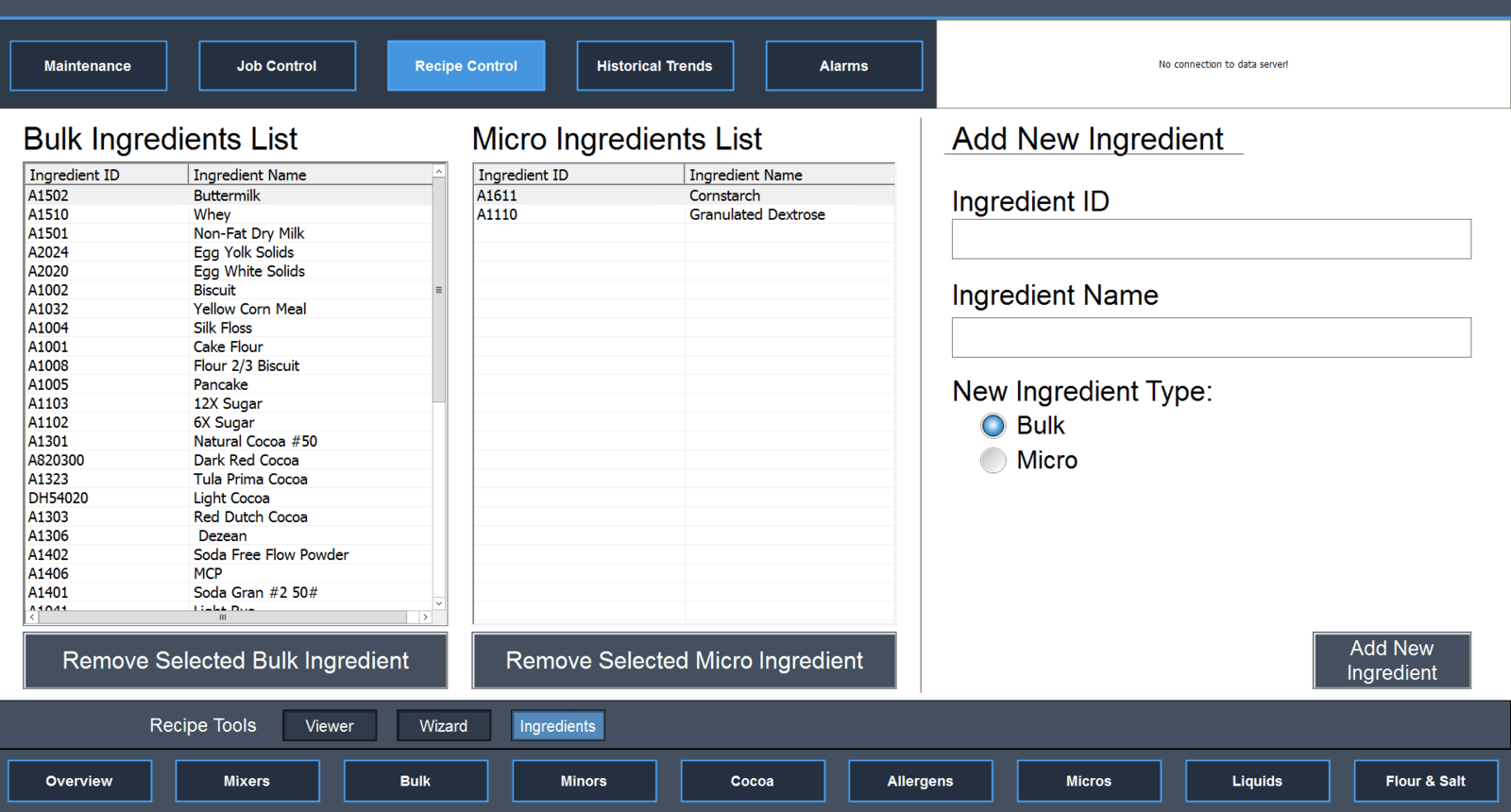

Figure 3 The Ingredient Screen allows for the list of available ingredients to be easily expanded.

Future Development

Due to the success of this project, next steps include adding tracking and traceability features using another WinCC Premium add-on called PM-QUALITY. This will allow operators to generate reports that show various metrics on plant productivity.