The client had an existing Simatic IT system that allowed for the creation of recipes and sequences. This information was then sent to a PLC, which assembled the custom hydraulic pump. To make this process more efficient, DMC developed a Siemens PLC program that would automatically receive the sequence steps and parameters sent by the MES system and then correctly control the devices at each unique station. The flexible architecture we designed even allowed for each station to have a different setup of devices.

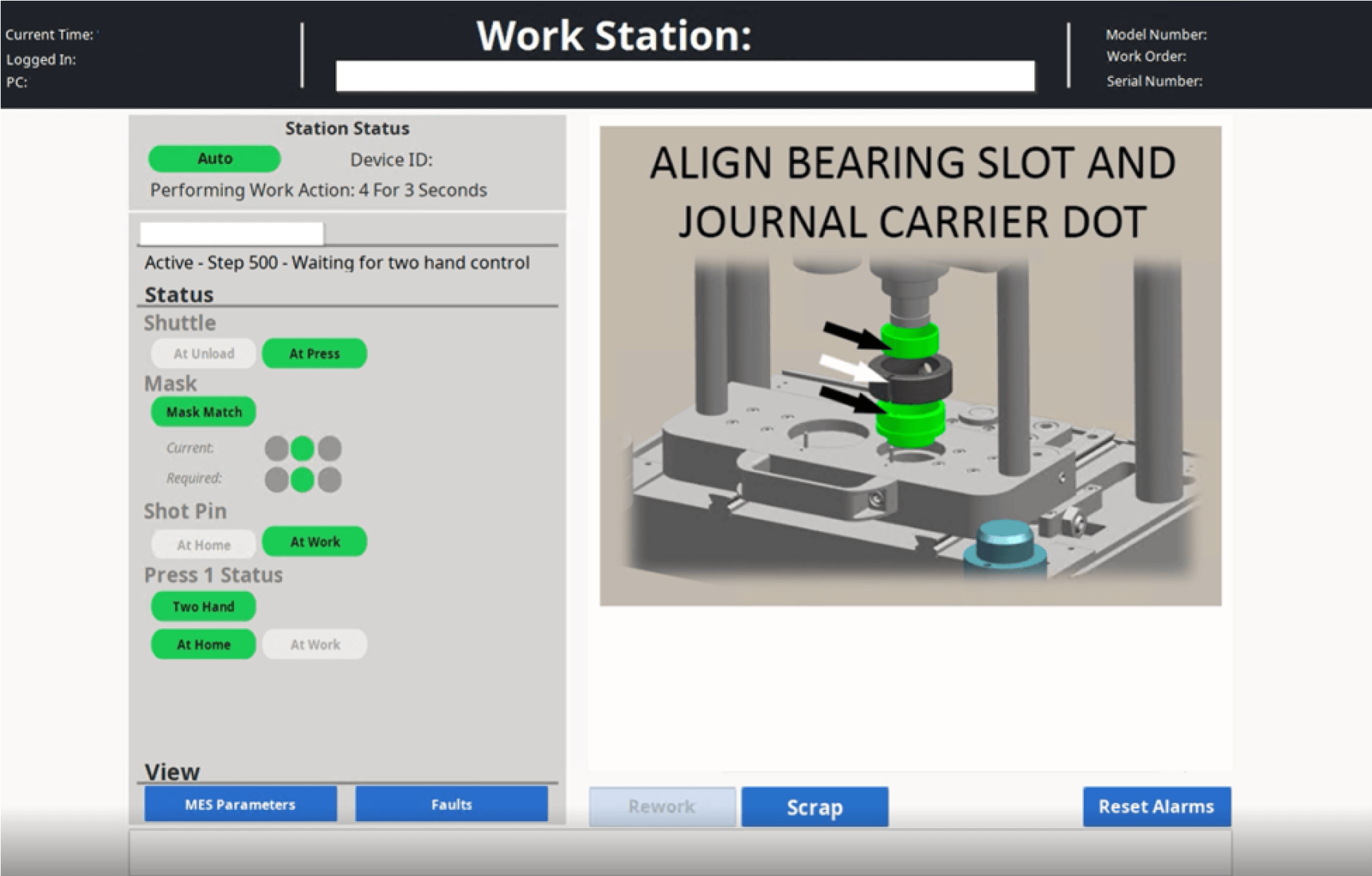

DMC utilized Ignition’s sequential function charts (SFC) module as a mediator between the PLC and MES by programming it to step the PLC through each of the recipe steps sent from the MES. We also designed custom templates in the HMI which allowed us to monitor and control different devices such as presses, motors, and air solenoids. The dynamic screen layout, shown below, displayed the template of the active device, making monitoring of the system intuitive and easy to navigate for the operator.

As an Ignition Premier Integrator, DMC has extensive experience in Ignition programming. Therefore, we also harnessed Ignition's flexible architecture and python modules to create dynamic screens and custom scripts that auto-generated large portions of the application with just a few configuration tags. In our case, up to 90% of the Ignition project was able to be auto-generated with these dynamic objects. This feature allowed for our customized system to be replicated at several lines in five different facilities. This saved the client both time and money by streamlining the implementation process across the different assembly lines.

Read more about DMC's MES expertise and contact us to get started on your next project.