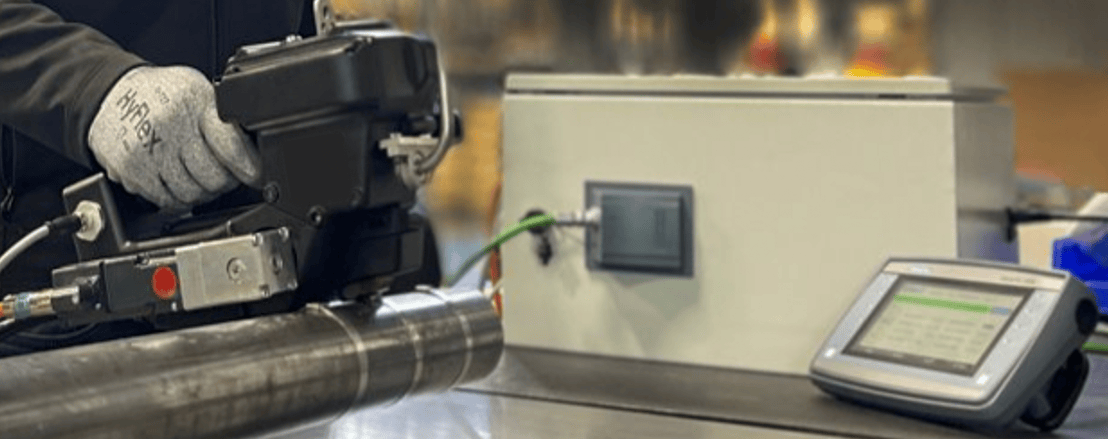

DMC worked with a mechanical design client to program a hand-held machine that tensions and cuts bands to length for fast and high-quality banding applications. The S7-1200 PLC provided speed and torque reduction to the S210 drive so that the drive would drive the band up to the required torque for a perfect band. While applying the proper torque, the S7-1200 checked pressures and sensor statuses, which improved quality and consistency for each band application.

The HMI provided real-time data and warnings for the tool, as well as logs and visualizations for quality control for each banding cycle. The PLC provided high-speed data collection for pressure, torque, speed, and sensors during each tension and cut cycle. The HMI then wrote that data to CSV files on an SD card. The most recent log was shown on a XY plot, and any log was available to be downloaded to USB.

Learn more about DMC's Siemens S7 PLC Programming expertise and contact us for your next project.