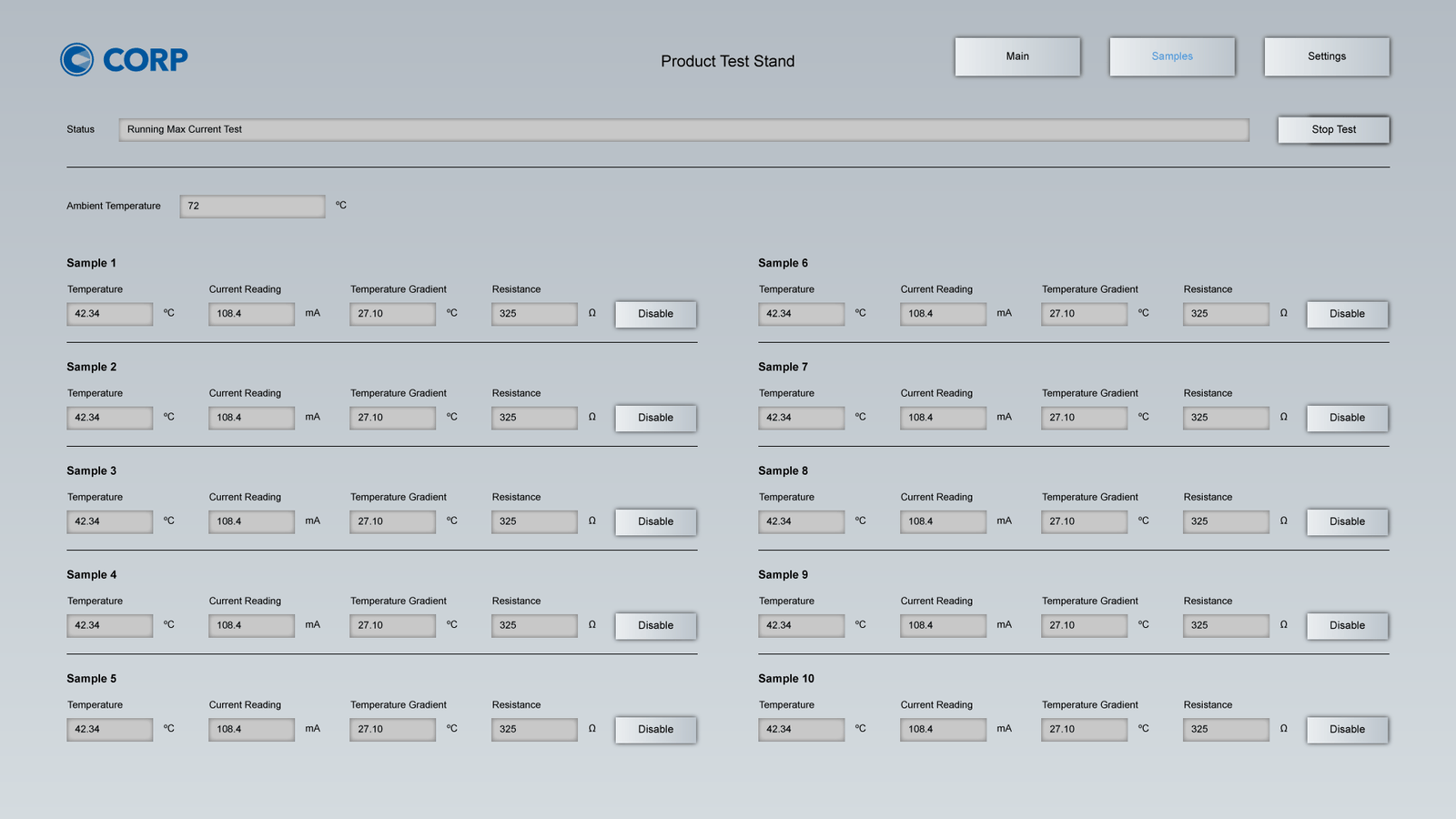

A client in the automotive industry tasked DMC with the development of an automated test system. This client required a system capable of testing products for extended periods of time, hours and sometime extending into days, while collecting data without operator or technician presence. DMC collaborated with Beckhoff and the client to specify the right Beckhoff hardware and IO based upon project requirements such as accuracy, precision, voltage and current ranges, and temperature conditions. DMC’s UX/UI design team worked with the customer to design an appealing and easy to use set of screens for the application.

The resulting automated test system measures electrical and thermal conditions of product over extended periods of time. This provides the client with a stable system for testing both new prototype product from a research development perspective, and production product from a quality assurance perspective. Detailed test results are logged to file and stored for future reference.