Automated Testing

For this project, DMC automated the client’s previously manual testing process. This increased efficiency while maintaining quality, as automated testing is faster and less error-prone. With our extensive experience in automated battery testing, we were qualified to follow the client’s step-by-step process and create a tester tailored to their needs.

Functional Specification

The test stand comprises a high-performing NI 4065 Digital Multi Meter (DMM), an NI RMX-4101 programmable power supply, and a Hioki ST5520 Hipot meter for measurement instrumentation. This test suite makes a wide range of testing options available to the client. A Pickering Switch Matrix and a Pickering High Voltage Multiplexer provide a robust switching infrastructure to allow additional instrumentation to be added or new test configurations to be defined depending on future product requirements.

Switch Matrix

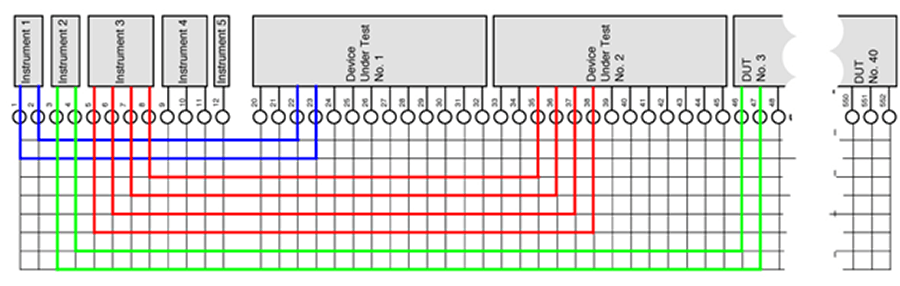

The core of the test system is built around a Pickering switch matrix which allows many connections between Device Under Test (DUT) signal lines and instrumentation. This is the heart of the test system's ability to adapt to changing product requirements.

Not only does the switch matrix allow the test stand to reconfigure a test setup in real-time, it also allows for the addition of instrumentation or DUT signals in the future with minimal changes to hardware or software.

Digital Multi Meter (DMM)

The DMM, in combination with the Pickering switch matrix, allows the test stand to make differential voltage measurements between any two DUT signals or single-ended measurements referenced to ground or the common line of the programmable power supply.

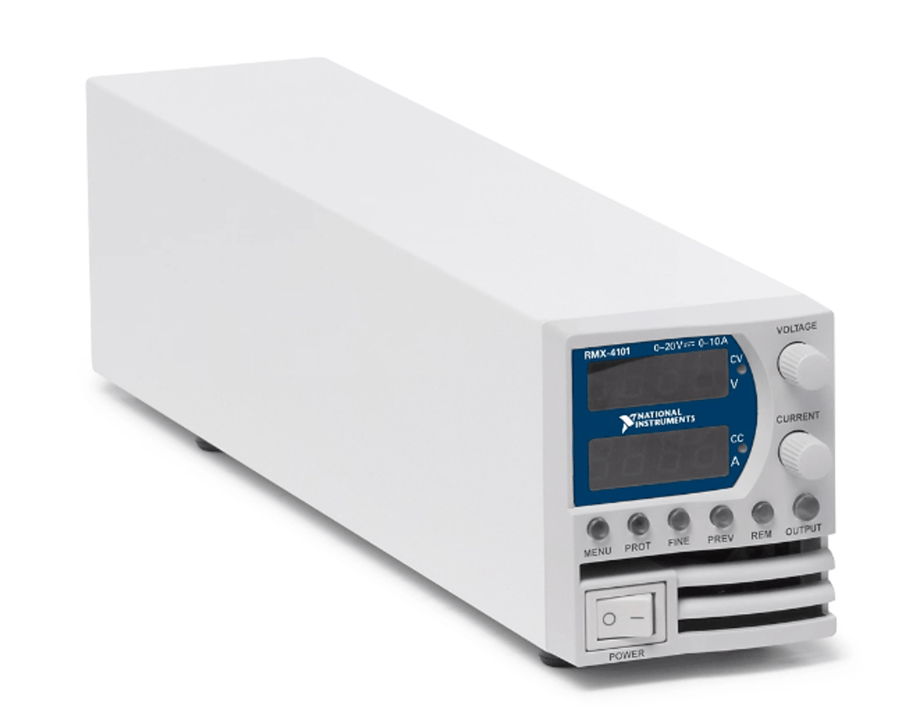

Programmable Power Supply

The PDU provided the power to the Battery Management System (BMS). The Programmable Power Supply (PPS) allows the test stand to apply a wide range of voltages or voltage profiles to the DUT, allowing the PDU to be tested under a wide variety of operating conditions.

The Hipot meter allows the test stand to perform Hipot testing on the DUT. In this case, the Hipot meter was combined with the Pickering high power 12 bank 2:1 multiplexer to provide high voltage isolation for up to 12 DUT lines.

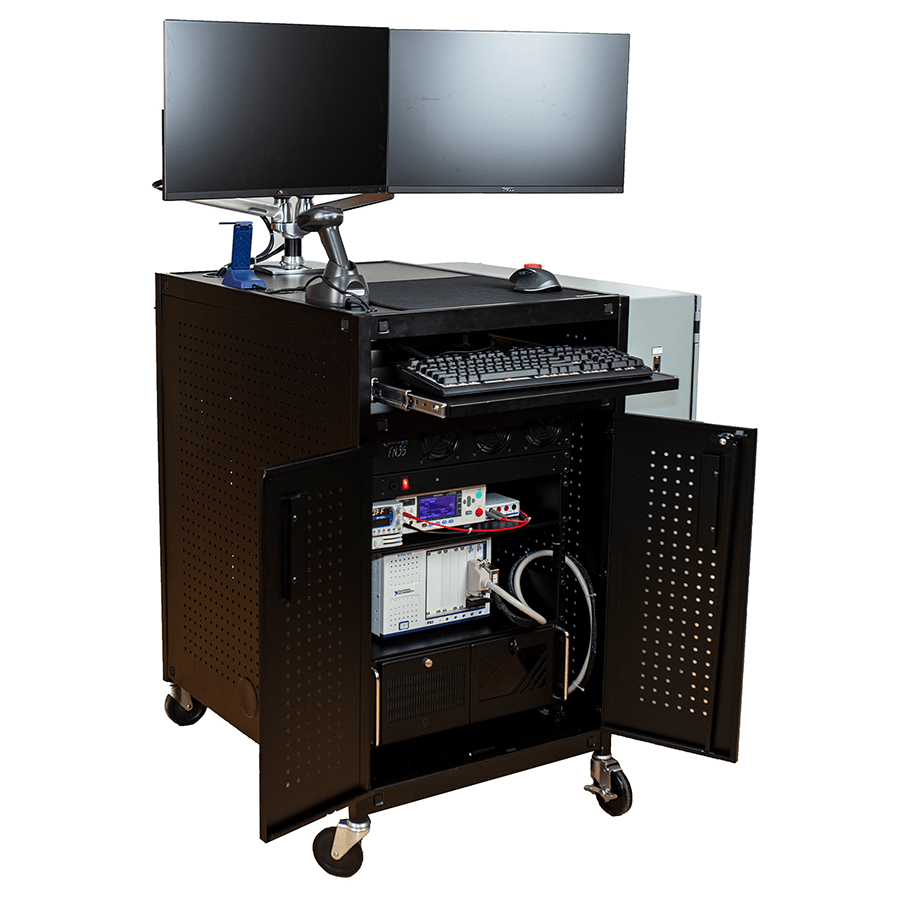

Stand Form

All of this measurement and switching hardware is contained in a compact rollable test cart. This test cart provides the operator interface along with the interface for the DUT.

Through the completion of this project, DMC has created a compact and flexible test stand that meets all of the clients' current testing requirements with the ability to adapt to future products. Having a system that is adaptable to a future product line reduces product development costs and allows for flexibility with new products as the client expands.

Through the completion of this project, DMC has created a compact and flexible test stand that meets all of the clients' current testing requirements with the ability to adapt to future products. Having a system that is adaptable to a future product line reduces product development costs and allows for flexibility with new products as the client expands.