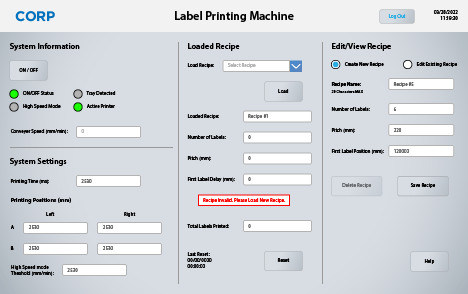

For this solution, DMC recommended Beckhoff hardware. Engineers began the process by specifying the system settings on the recipe management system. Next, they developed source code for the PLC and HMI technologies. DMC’s UX/UI team then designed mockups and official screens for the interface to match the client’s style guides. Lastly, engineers commissioned the system at the manufacturer facility and provided remote support upon completion.

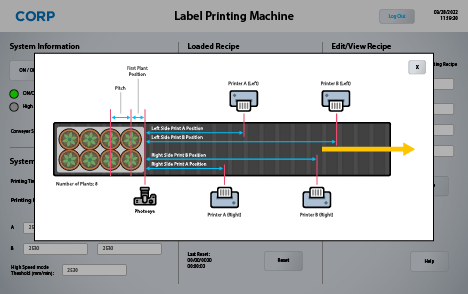

Using the TwinCAT 3 HMI Recipe Manager, the solution was configurable to a variety of printing applications and production lines. It supported modes for high-speed and low-speed application and allowed operators to easily configure and support a variety of product geometries. Additionally, it allowed for the application of labels without stopping conveyor motion.

DMC provided software for several identical programs. The client sent DMC engineers the necessary hardware. DMC engineers then loaded the software and shipped the hardware directly to the end customer with no commissioning required.

DMC engineers have created a blog series detailing this process.

Learn more about DMC’s TwinCAT3 programming experience and contact us for your next project.