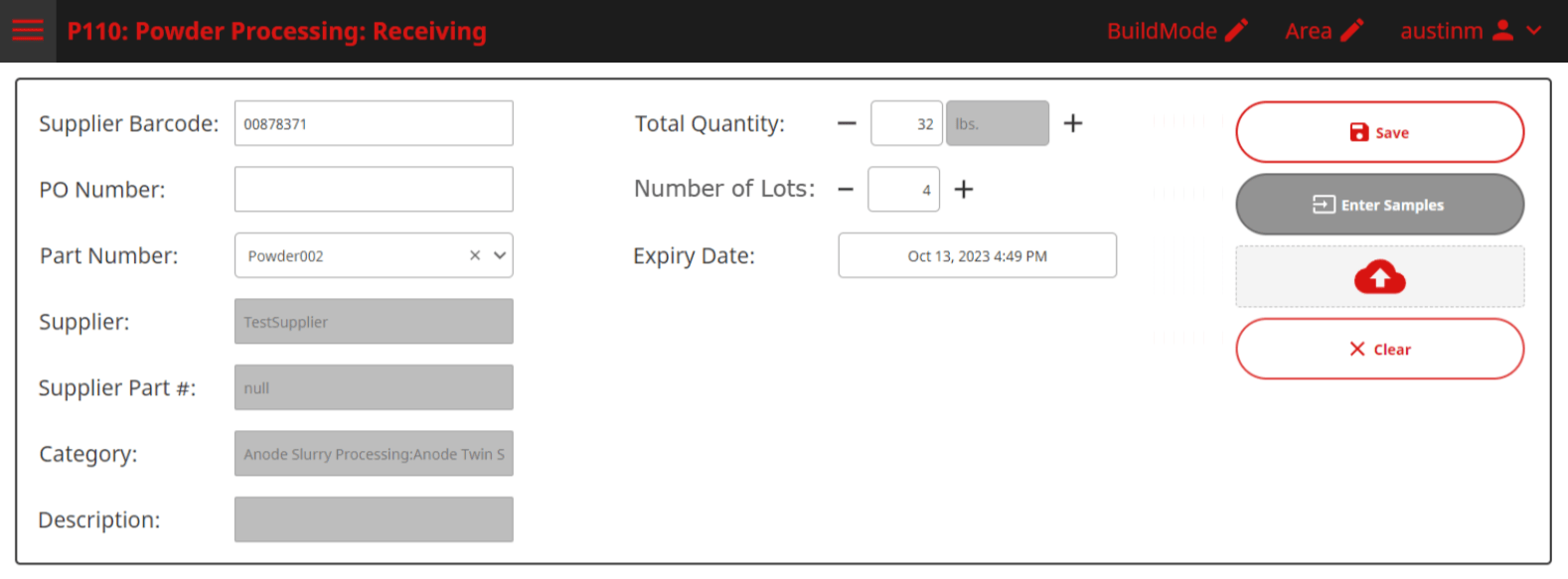

Prior to working with DMC, the client’s information was maintained through a custom-built solution, which made it difficult to configure operations or capture data for analysis without a deep understanding of their database. To automate this system, DMC’s team implemented an MES solution. This centralized all information into Sepasoft, allowing users to sample materials, execute operations, and maintain quality control without the need to maintain a database if changes are needed.

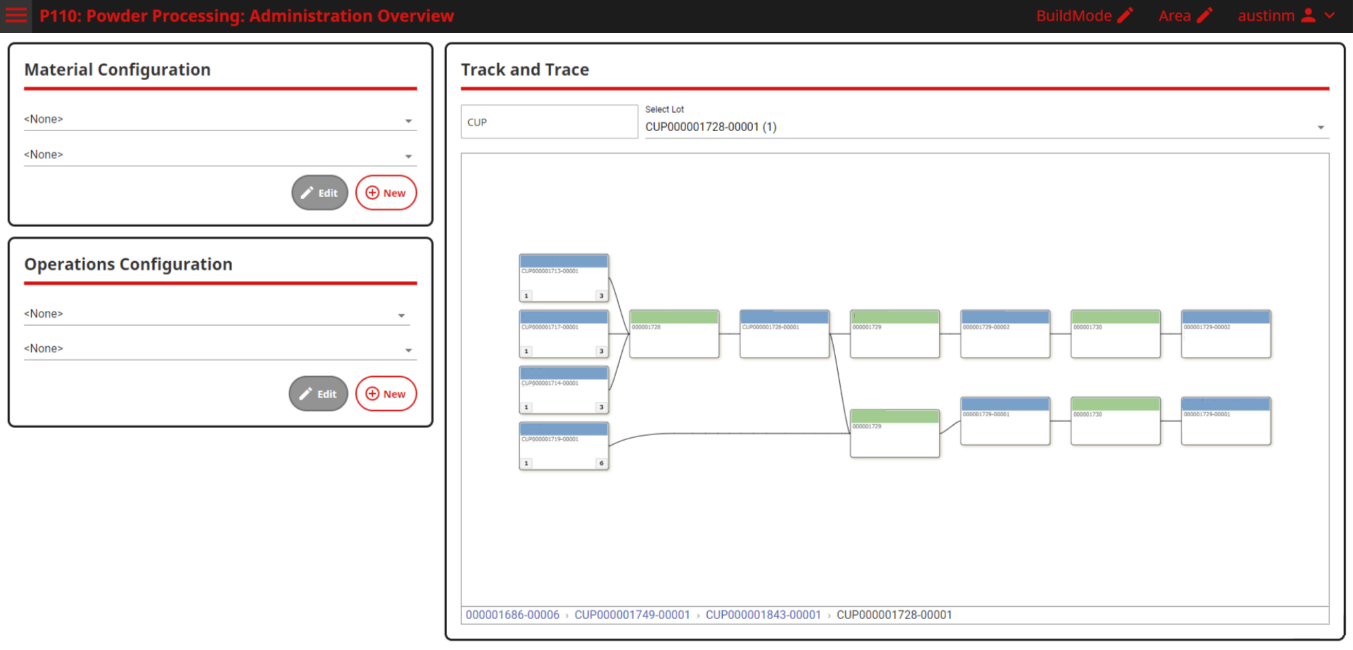

The application uses the Sepasoft Track and Trace module, the Sepasoft SPC module, and the Ignition Perspective module to track products and ensure the quality of materials and end products as they are passed through quality control checks along the process. Since this manufacturer has multiple sites, consistency across sites was key: which is why Sepasoft is synced with Aras PLM to maintain materials and processes across work centers.

DMC also condensed multiple HMI projects into one central project while still maintaining granularity for unique needs across process areas, allowing administrators to monitor the whole process without needing multiple devices.

Migrating from a custom-built solution to a Sepasoft solution allowed for a code base that is much easier for the end customer to maintain and scale out as new equipment is added. Using as much Sepasoft out of the box functionality as possible, DMC approached this project with the goal of a low code MES. This resulted in less engineering time spent adding features and a more consistent and reliable data structure across the client's facility.

Learn more about DMC's Sepasoft Programming expertise and contact us today for your next project.