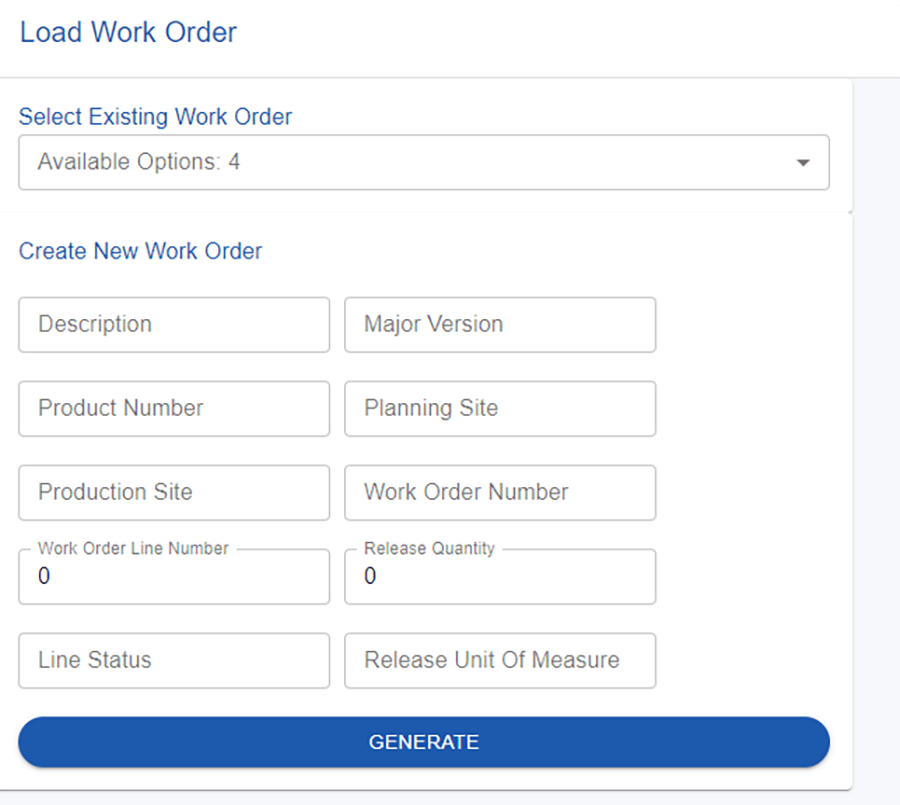

While working virtually due to the pandemic, DMC worked with the client to develop and test everything remotely using Siemens Opcenter. To meet the client's required performance rates, our engineers optimized the Opcenter installation as well as added additional customization to handle transactions on a batch basis as opposed to one at a time. We did this by writing a custom UI/UX to Opcenter using ASP.Net and Microsoft IIS. This provided a simpler interface for operators to use and allowed for faster throughput for tracking manual operations.

DMC ultimately designed a method to quickly track the history and serial number of every piece of the subassembly as it moved through the assembly project to determine if anything had a quality issue in the manufacturing process.

Learn more about DMC's Manufacturing Automation & Intelligence expertise and contact us for your next project.