The client came to DMC for help designing a new, high-current, compact motor controller that could be easily integrated into their current and future lines of motors. It was important to the customer that the system was extremely efficient, small, and compatible with nearly any application.

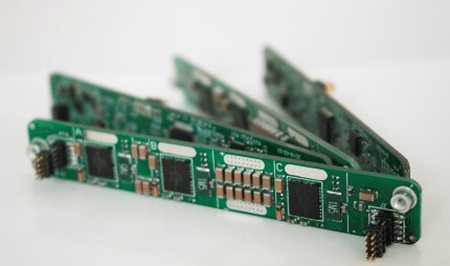

Image of PCB

The project started by evaluating different motor control technologies from the leading motor control vendors in the industry. Controllers must be able to operate in both sensored and sensor-less modes, be easily reconfigured to drive different motors in different applications, and be tunable on the fly to properly match the needed application.

TI MotorWare technology proved to be a great fit for these requirements. DMC then developed software to expand and optimize the TI MotorWare project to address the client’s need for a near universal PMSM motor controller.

DMC worked closely with the client to design the custom PCBs for the controller and power electronics. These PCBs had to fit in an extremely small envelope to be used with the client’s smallest devices while also having the efficiency and thermal dissipation to effectively drive the client’s more powerful motors. We achieved this with a highly integrated design between the housing and PCB. With this, we used the latest Intelligent power modules from Infineon that allowed for high peak and sustained currents in a very compact design by integrating a half bridge and mosfet drivers into a single IC.

Learn more about DMC's Embedded Development and Embedded Programming expertise and contact us today for your next project.