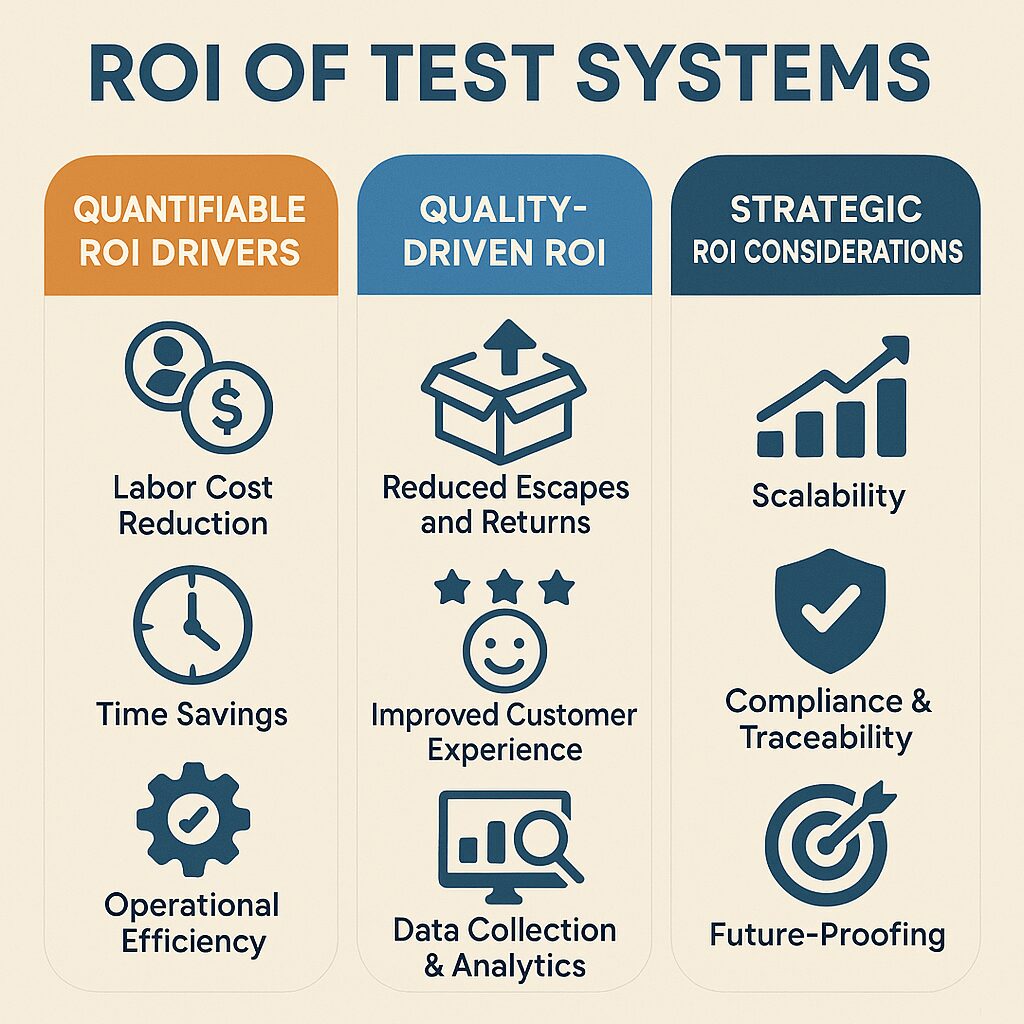

Automated Test Equipment (ATE) offers a compelling value proposition, but its upfront cost often raises questions. This blog explores how to justify the investment by calculating ROI across quantifiable savings, quality improvements, and strategic advantages. Whether you’re evaluating a new system or defending an upgrade, understanding the complete ROI picture is key.

Quantifiable ROI Drivers

These are the most straightforward “easy wins” metrics to model. They directly translate into reduced operational costs and measurable throughput improvements.

Labor Cost Reduction

Automated systems limit manual test execution and data entry, while a single operator can manage several automated test stations at any one time, so that your team can accomplish more with fewer people. Training and onboarding new employees can now take less time and be easier, as procedures are embedded in software as opposed to being tribal knowledge. Automation also reduces human error through less manual handling, minimizing retests, scrap, and time spent diagnosing errors that shouldn’t have occurred. All these time savings add up to significant cost efficiency.

Time Savings

Automated testing significantly reduces the length of tests by minimizing the time between actions, gathering data efficiently, and minimizing the time it takes to change configurations. Faster-changing hardware allows for greater time savings — saving seconds of time, and even minutia of time on a per unit basis, adds up across hundreds to thousands of units. Similarly, with automation, downtime is reduced, systems can run continuously and/or during off-hours, and minimize break time impacts.

Operational Efficiency

Automated Test Equipment consolidates the control, monitoring, and scheduling of tests, resulting in more consistent performance across lines and sites. With automation using test sequencing, test assets can now be shared dynamically, rather than being tied to a single operator or station. This enhanced utilization of assets reduces idle time and helps distribute workload to avoid balancing loads across the manufacturing floor. Bottlenecks can often be caused by manual test setup or inconsistent test execution; however, automated workflows are standardized to reduce these problems. The result is improved production flow, fewer delays, and increased predictability.

Quality-Driven ROI (Harder to Quantify but Critical)

While it may be harder to express in pure dollars, quality improvements often deliver the largest and most enduring returns.

Reduced Escapes and Returns

Automated systems will compute all test sequences with the same level of consistency, providing validation that is consistent across all units. This reduces the likelihood of defects “escaping” into the field, which could result in expensive warranty claims and additional rework. Consistency also helps identify intermittent issues that can go undetected by visual inspection. Raising and catching these issues early allows firms to avoid possible recalls and preserve their reliability reputation—a form of ROI that preserves revenue and market share over the long haul.

Improved Customer Experience

Customers recognize reliability. When the products you sell work consistently, confidence is built—and that converts to loyalty, referrals, and ongoing partnerships. ATE systems help generate consistent test data, speed up troubleshooting, and shorten the time to fix issues. With traceable records for every unit, engineering and support teams can identify the causes of failures faster and limit the downtime experienced by customers. This cycle of test data and customer experience can elevate your brand and position it better against competitors in the market.

Data Collection & Analytics

Data engines drive modern automated test systems. They collect detailed information related to measurements, limits, timing, and environmental conditions—data that can fuel future insights. This data facilitates predictive maintenance, enabling recommendations and implications to be made before a failure. It also facilitates root cause analysis and continuous improvement efforts, allowing teams to identify performance trends and make improvements proactively. Over time, the capability to mine data and take action will become a significant differentiator between companies that test and those who test continuously to optimize.

Strategic ROI Considerations

These are broader business impacts that support long-term growth:

Scalability

- Easier to replicate across sites

- Supports growth without linear cost increases

Compliance & Traceability

- Automated logs support audits and certifications

- Reduces risk of non-compliance penalties

Future-Proofing

- Modular systems adapt to new product lines

- Supports evolving test requirements

Conclusion

Calculating ROI for Automated Test Equipment requires looking beyond the obvious. While labor and time savings are easy to quantify, quality improvements and strategic benefits often deliver the most lasting value and can be very difficult to estimate firmly. By considering all aspects—from operational efficiency to customer satisfaction—organizations can make informed decisions and justify their investment in ATE.

If you need help, DMC is here to help your team evaluate ROI for your specific use case. We can also consult with you on what others have done in similar circumstances and offer different approaches to address your challenges. Contact us to speak directly to an engineer who can help.