Why Your ECU Software Download Station Matters More Than Ever

Electronic Control Units (ECUs) are the digital brains behind nearly every system in modern vehicles, from classic engines and transmissions to battery management systems, inverters, and DC-DC converters. As vehicles become more connected and software-driven, and move toward new concepts like zonal controllers, the need for secure, efficient, and flexible ECU programming in production environments has never been greater.

Manufacturers face mounting challenges like exponential growth in calibration parameters, evolving cybersecurity requirements, and the increasing size and complexity of ECU firmware. Throw in the need to program ECUs for multiple OEMs and specific end-users across multiple manufacturing lines inside facilities distributed around the globe, and the ‘simple’ process of flashing an ECU can quickly become a tangled mess.

Industry Trends: Why Clients Need to Stay Ahead of Cybersecurity and Complexity Challenges

Modern ECUs are increasingly targeted by cyberattacks, and the size and sophistication of ECU firmware is growing rapidly. Manufacturers must stay ahead of cybersecurity and complexity challenges to ensure robust, future-ready ECU software management. DMC’s Production ECU Software Download Station provides a turnkey platform that addresses these needs, while offering the flexibility to customize the system to unique client requirements.

The Challenge: Complexity, Security, and Cycle Time

Traditionally, manufacturers have adapted existing assembly line stations, often at End-of-Line (EOL) test, to handle ECU programming. However, this approach is fraught with issues:

- Flashing software is slow and error-prone if not done correctly.

- Modern ECUs require multiple software components like bootloaders, memory configuration, customer-specific calibrations, and evolving security libraries.

- Cybersecurity requirements are increasing. ECUs are now targets for hackers seeking to exploit vulnerabilities in vehicle networks, firmware, and diagnostic ports. The ISO 21434 standard and SAE guidelines now mandate robust cybersecurity engineering for automotive systems.

- Cycle (TAKT) time is impacted. Adding ECU software download steps to critical stations cuts into overall production efficiency (OEE).

The DMC Solution: A Digital Assembly Line for ECU Programming

DMC’s Production ECU Software Download Station is designed to address these challenges head-on. Built on the DMC Cortex Framework and leveraging robust NI cDAQ hardware, this solution offers:

- Object-Oriented LabVIEW-based software for flexible and scalable automation.

- Support for NI XNET, Vector and 3rd party interfaces for CAN, LIN, and Automotive Ethernet communications.

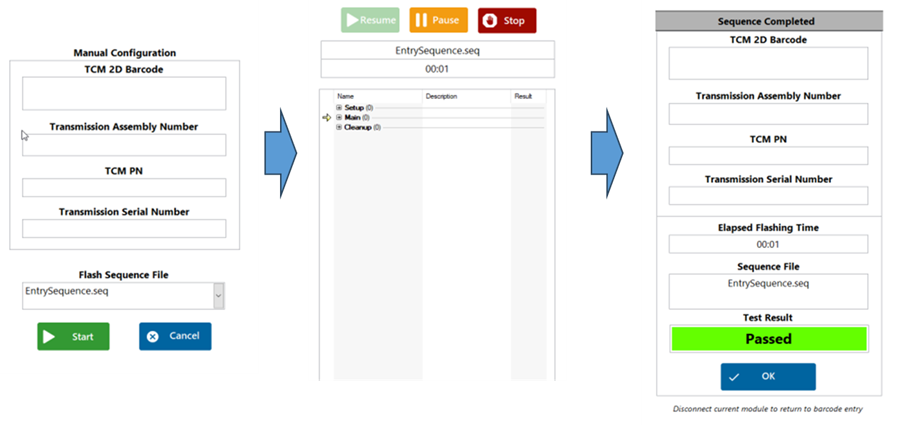

- NI TestStand integration for easy download sequence definition and customization.

- Ready for Hi-Mix Applications. This solution easily supports multiple ECU variants and a high mix of models and end-product configurations.

- Compact station design capable of programming 4, 8, or more ECUs asynchronously in parallel, reducing floorspace requirements and saving cycle time for capital-intensive assembly and test processes.

- Assembly Line-Ready. Most typical machine builder/PLC interfaces (Modbus, EthernetIP, Profinet, etc.) are supported for connection to assembly line tooling and systems.

Key Features and Specifications

| Feature | Details |

| Industries | Automotive, Commercial Vehicle, Truck, Bus, Off-Highway, Construction, Marine, Aerospace |

| Controller | Windows PC-based |

| System Size | 20U rack: 24”W x 32”D x 44”H |

| Download Methods | NI XNET LabVIEW code or Vector Vflash Station wrapper |

| Communication Bus and Protocols | CAN/CAN-FD [SAE J1939, UDS, XCP/CCP, and/or proprietary], LIN, Automotive Ethernet(100/1000BASE-T1) |

| Data Reporting | Custom formats via NI TestStand; MES/database integration optional |

| Data Entry | Keyboard & 2D Barcode Reader; MES integration optional |

Real-World Success: Case Studies

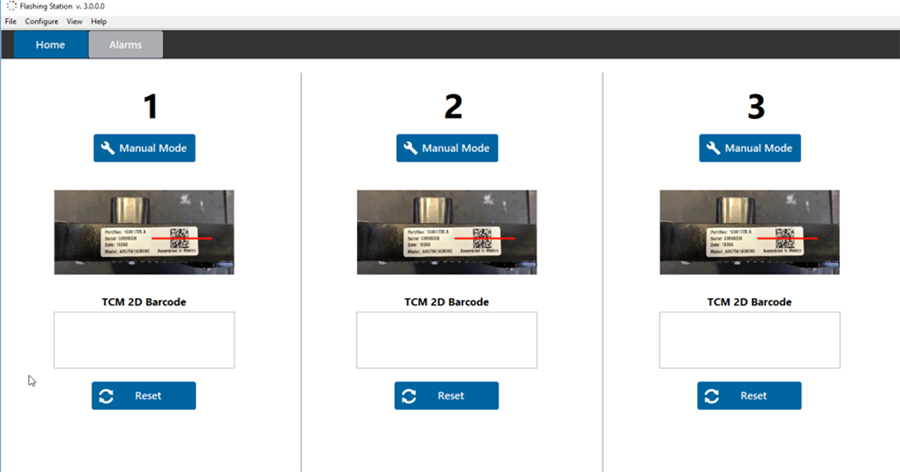

- Automotive Flashing Station for End-of-Line Test

DMC delivered a robust 4-UP ECU flashing solution for an automotive client’s assembly line using the NI toolchain to eliminate ongoing licensing costs. The delivered system enabled secure, efficient, and parallel programming of 4x ECUs with the latest firmware and calibrations. The DMC system increased data and process organization thereby reducing the time needed for the Client’s engineering teams to release updates to their assembly lines and eliminated opportunities for misconfiguration of the system.

Read the full case study: Test Stand Automative Flashing Station - 8-Up ECU Flashing Station

For another client, DMC implemented an ECU flashing station capable of programming up to eight ECUs simultaneously, using the Vector toolchain, dramatically improving throughput and reducing cycle time. Use of the Vector toolchain reduced flash package development and deployment time for the client’s controls software team.

Read the full case study: 8-Up ECU Flashing Station

Download the Full Solution Brief

Download DMC’s ECU Production Software Download Station solution brief.

Why Work With DMC?

DMC is a leading systems integrator with decades of experience in test system automation and hardware/software integration for production lines and R&D labs. With a nationwide presence, worldwide delivery capability, and stable long-term support, DMC delivers solutions that are both robust and adaptable.

“They truly took ownership and pride in their end of the project, ultimately resulting in an outstanding working relationship and final product. We will continue to work with and recommend DMC for future projects.”

— Jeff Wasil, Associate Engineer at BRP

Beyond Flashing: Embedded Firmware & Application Development

DMC’s team doesn’t just build test stations—we also develop embedded firmware for ECUs, ensuring seamless integration and optimal performance. Learn more about our capabilities:

For clients managing large fleets of ECU download stations, server- and cloud-based applications for station management and data collection are a natural extension of our platform. These additional solutions can help centralize control and security, streamline system updates, and provide powerful analytics and dashboards for production-ready operations.

Explore our Application Development services.

Need Help or Have Questions?

Learn more about DMC’s Test & Measurement Automation expertise and contact us to discuss your specific requirements.