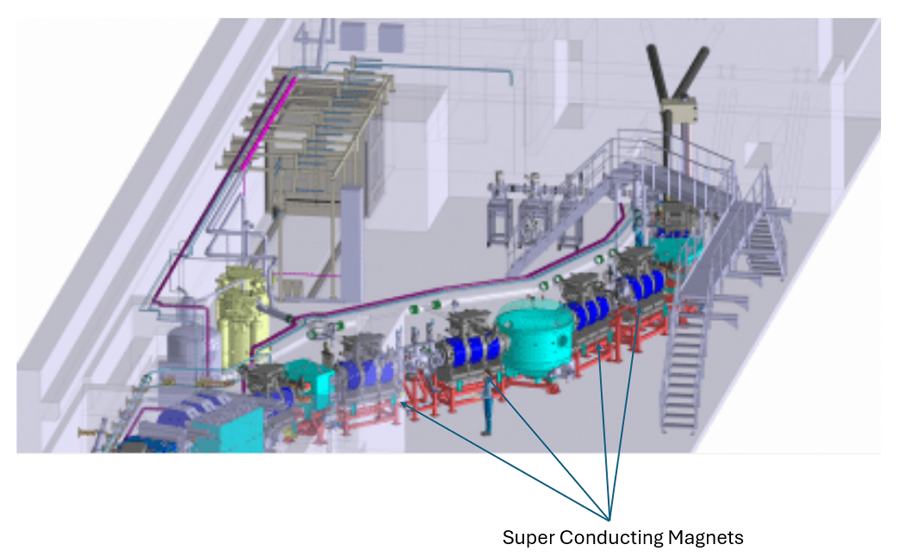

A few years back, I had the opportunity to work on a fascinating project with scientists at GANIL (Grand Accélérateur National d’Ions Lourds) in France, in collaboration with Advanced Magnetic Labs (AML) and Argonne National Laboratory (ANL). Together, we commissioned a set of superconducting magnets used to steer a particle accelerator beam. I have always wanted to write more about that project purely because I enjoyed the engineering, physics, and science behind it.

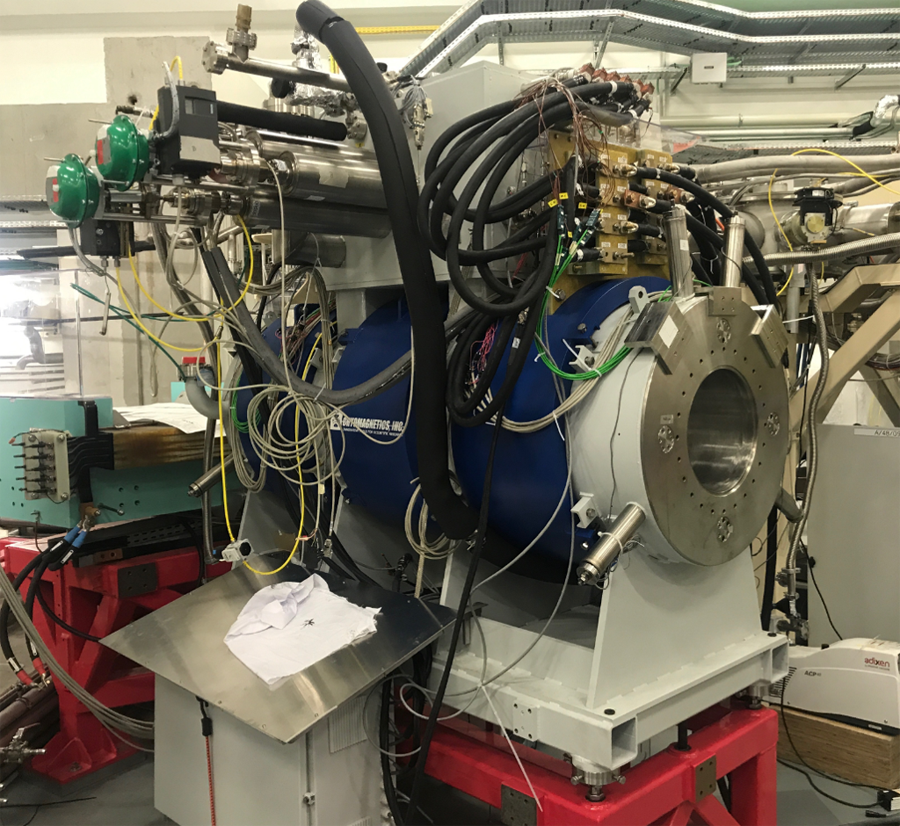

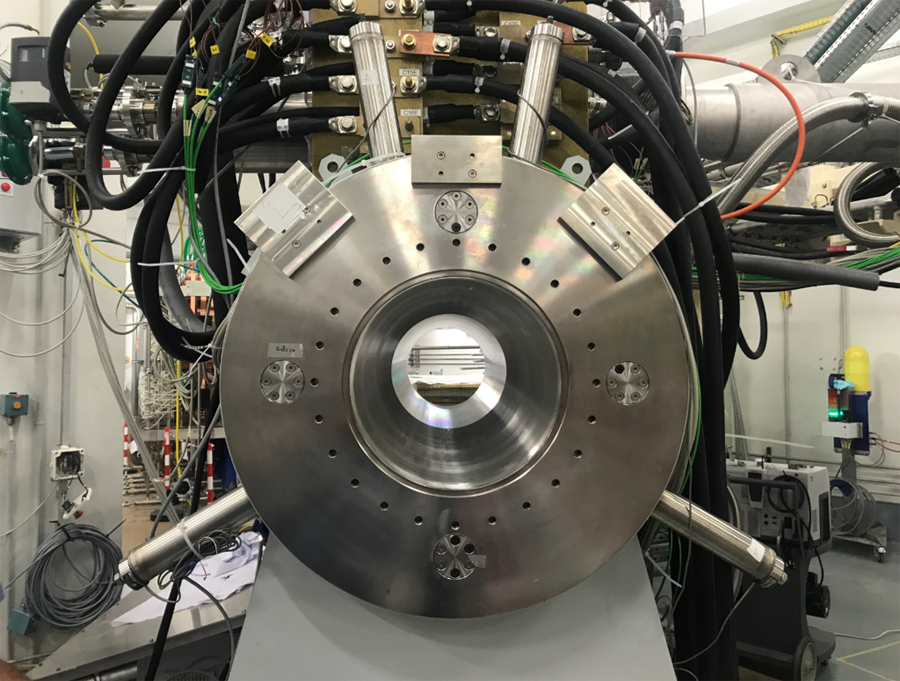

The magnet was part of the SPIRAL2 facility, which came online in 2019 to support nuclear physics and nuclear medicine research. My role was to design and implement the control application for the superconducting magnet system. This project combined real-time control, cryogenics, and some truly elegant physics, and it remains one of my favorite engineering experiences.

What Is a Superconducting Magnet?

A superconducting magnet is, at its core, an electromagnet built with superconducting wire. A material that, when cooled below a critical temperature, has zero electrical resistance.

In a conventional electromagnet, large currents are required to generate the strong magnetic fields needed to steer or focus a particle beam. However, large currents also produce heat due to resistive losses in the copper windings. To handle that heat, you need thick wire, but thicker wire makes it harder to pack enough turns into the coil to get the desired field strength. It’s a classic engineering catch-22.

Superconductors solve this problem beautifully. Once cooled below their critical temperature (often below 10 Kelvin, and sometimes as low as 4.2 K in the case of the liquid helium we were using) the material carries large currents with essentially no losses. The result is a magnet capable of producing enormous field strengths in a compact design.

Quench Detection: Preventing a Chain Reaction

Superconductors do come with their own challenges. If any part of the magnet warms above its critical temperature, the material suddenly becomes resistive again. This transition, called a quench, causes rapid heating, which can boil the surrounding liquid helium, increase pressure, and if uncontrolled, lead to catastrophic failure.

To prevent that, the system includes a real-time quench detection algorithm that monitors temperature and voltage throughout the coils. If a potential quench is detected, the system safely vents the helium and ramps down the current to prevent damage.

Part of my job on the project was integrating this monitoring logic and ensuring that the magnet could transition safely in and out of its operating state without triggering false alarms or damaging the cryostat.

The Cool Part: Controlling Current in an Ideal Inductor

From a controls perspective, this was where the project got really exciting.

In most electrical systems, you can’t ignore resistance —it’s what turns voltage into heat. But in a superconducting magnet, resistance drops to zero, so the magnet behaves almost like an ideal inductor.

That means we can use the familiar equation:

V = L (di/dt)

to directly control the rate of change of current simply by adjusting voltage. Rearranging gives:

di/dt = V / L

This relationship means a small, precisely controlled voltage allows us to ramp current smoothly to hundreds of amps with incredible precision. This is just like pressing the accelerator pedal in a car to control speed. The current in the magnet directly determines the field strength, so voltage control gives us a precise handle on the beam-steering field.

The Control Algorithm: Ramp and Hold

The control algorithm had two key responsibilities:

- Ramp the magnet current at a precise, limited rate to prevent quench conditions.

If the current increased too quickly, it could cause localized heating and trigger a quench. Preventing that avoided costly downtime and helium loss, since recovering from a quench event can take hours or even days while the system re-cools to cryogenic temperatures.

- Hold the magnet current at a stable value to maintain the desired field strength.

While the magnet coils themselves are superconducting, the power leads and cables connecting to the magnet are not — so small voltage adjustments are still needed to compensate for resistive losses. It’s like keeping your foot gently on the accelerator to maintain cruising speed.

Deployment at GANIL

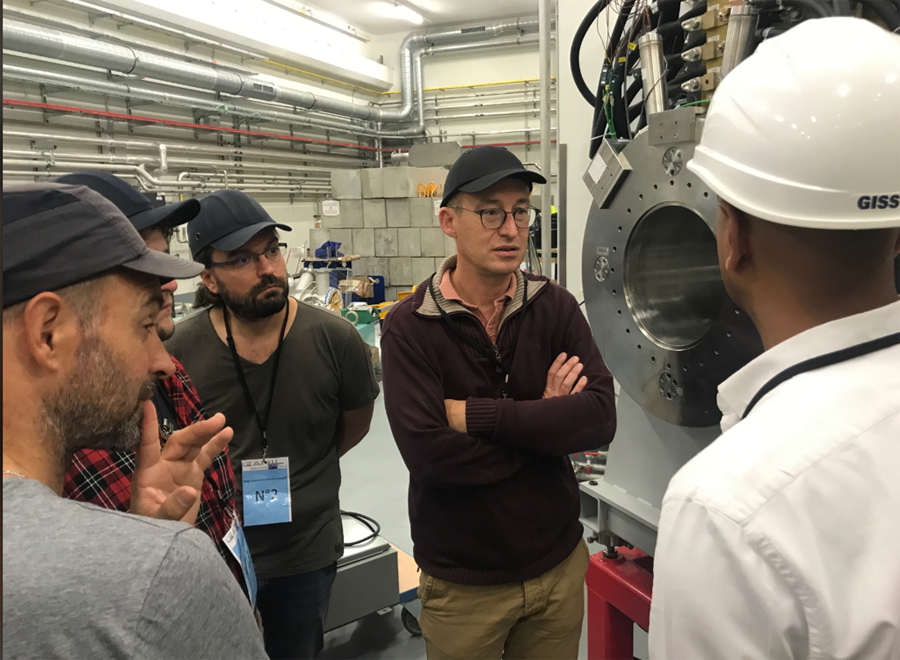

After several months of development and testing, we deployed the control application at the GANIL SPIRAL2 test facility in Caen, France. Once the control and quench detection systems were validated, the team moved forward with commissioning the remaining magnets.

Seeing the system perform as designed, holding enormous currents stable within fractions of an amp and responding safely to temperature changes, was a deeply rewarding moment.

Today, that superconducting magnet is part of an operational research facility contributing to advances in nuclear medicine and fundamental physics. It’s a great example of how precise controls engineering can help enable groundbreaking science.

Engineering at DMC involves all kinds of projects, many of them in R&D like this one. I’ve found that some of the most innovative solutions come from combining our controls programming expertise with the amazing scientists at places like AML and ANL. If you’re looking to add engineering support for controls, programming, or data acquisition to your cool science, contact us today so we can work on something innovative together.

Learn more about DMC’s Test and Measurement expertise, and contact us today to discuss how we can help you achieve your goals.