At DMC, we engage with many customers, large and small, in a variety of different industries. That variety allows unique insights into issues many organizations struggle with, that only some of them even notice, and a select few see as an opportunity to improve.

One of these issues is that many organizations struggle to strike the right balance between internal ownership and external execution when it comes to developing and sourcing their test systems. Some try to do everything in-house and run into bandwidth and/or capability issues. Others outsource too much, losing product-specific expertise, struggling with decision making and alignment of internal stakeholders, and lacking any cohesive testing strategy. Perhaps worst of all are the customers we have worked with long enough to see them periodically cycling between these two ends of the spectrum, as they overcorrect issues observed during their latest attempts at sourcing test systems.

At DMC, we’ve seen the most successful clients follow a hybrid model—one that empowers internal test engineers to lead strategically while leveraging external experts for test system execution and technical innovation.

The Pitfalls of Going It Alone

Relying solely on internal teams to ‘do it all by themselves’ can lead to:

- Resource bottlenecks: Internal engineers often juggle multiple priorities and lack time for deep system development.

- Limited exposure: In-house teams may not be familiar with the latest tools, platforms, or test strategies across industries.

- Missed opportunities: Without external input, test systems may be overbuilt or misaligned with budget and timeline constraints.

- Over- and under-staffing: Depending on how often your business needs new or updated test systems, you are either paying for engineers to sit on the bench or constantly resource constrained.

- Getting lost in the weeds: Engineers may place too much focus on technologies and software architectures rather than testing process effectiveness, efficiency, and overall product quality.

Misdirected Internal Engineers: A Hidden Risk

On the flip side, some organizations bring in external partners to deliver their test systems and fail to prepare and engage their internal test engineers effectively. Without preparing your internal test engineers, they may act as ‘internal competition’ to the external team. Some clients believe they don’t need any internal test engineer involvement once they make the decision to use an outside partner.

These mistakes often result in:

- Missing, incomplete, or total lack of requirements and test specifications

- Poor stakeholder communication and misalignment on goals

- Trouble making engineering and project trade-offs quickly

- Lack of ownership for test system validation and deployment

- Internal test engineers feeling “left out” of the process and marginalized

Best Practice: Strategic Internal Ownership + Expert External Execution

The most effective model we’ve seen used by customers is a hybrid model that fits somewhere in between the two extremes, with internal and external resources playing roles based on their strengths and in constant communication.

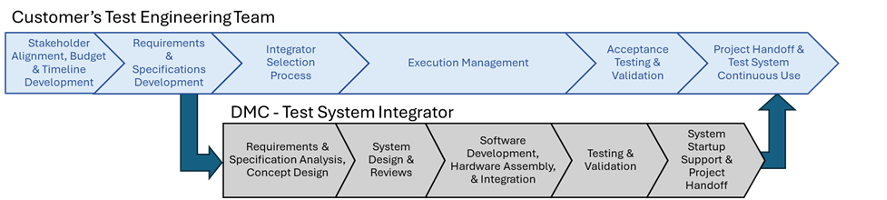

Internal Test Engineering Team Owns:

- Budget and scheduling allocation and processes

- Overall stakeholder alignment, from the beginning to the end of the project

- Understanding the critical product functions and test specifications

- Providing subject matter expertise for any industry or customer-specific technologies required, or acting as an intermediary with internal team members

- Producing clear requirements and definitions to the external team, ensuring expectations are realistic, testable, and traceable

- Providing project management during the execution phase

- Leadership of test system validation and acceptance testing, to ensure the delivered system meets performance, quality, and usability goals

- Long-term ownership of the delivered test system, calibration, maintenance, overall testing process, and data analysis and monitoring

External Test System Integration Partners Bring:

- Consultative insight into meeting test goals within budget and time constraints while maintaining a consistent overall testing strategy

- Knowledge of the latest best practices across many industries and lessons learned from the execution of dozens of test and measurement projects per year

- Up-to-date technical know-how and subject matter expertise in platforms like NI LabVIEW, TestStand, SystemLink, and cloud-enabled test environments

- Scalable system architectures with support for global deployment, multi-channel systems, and integration with any laboratory or factory-floor systems

- Efficient execution of test system design, build, and deployment

- Proper software development practices, including testing, integration, code reviews, revision control, documentation, and release

- Full hardware system management, including design, customer reviews, drawing revision control, design release processes, fabrication, system startup and testing, documentation, and subcontractor and supplier oversight

- High-level troubleshooting and maintenance assistance after system startup

Case Study Examples

DMC’s recent work on ECU (electronic control module) and BMS (battery management system) EOL (end-of-line) test systems illustrate this model well. The customer’s internal test engineering teams defined the performance goals and test specifications and frequently consulted with DMC on a few critical requirements to ensure they could fit within their tight budget and schedule demands. From there, DMC executed the system design, software development, test stand build, and validation. The result was delivery and handoff of a robust, scalable solution that met quality and production needs without overburdening internal resources.

- Bed of Nails Battery Management System PCB Test Station

- Functional End of Line Test System for Automotive ECUs

Conclusion

The key to success isn’t choosing between internal and external routes to test system delivery—it’s knowing how to combine them effectively. Organizations can build smarter, faster, and more cost-effective test systems by: (A) empowering their internal test engineers to manage and lead strategically and (B) partnering with experienced external teams like DMC for execution.

We Can Help

If you’re looking for consulting or support as you navigate the complexities of effectively outsourcing your test system development, give us a call!

Contact us today to learn more about our Test and Measurement expertise and how we can help your team achieve its goals.