In many automated test environments, the ability to efficiently measure and analyze multiple differential signals is essential. Traditional oscilloscope setups often require manual cable changes, fixed signal routing, or multiple scopes or scope channels to accommodate extra signals. When the number of signals exceeds the oscilloscope’s available input channels, this approach quickly becomes inefficient and expensive.

To overcome these limitations, our team designed a custom oscilloscope multiplexing system for differential signals, integrating PXIe switching hardware, custom cable harnesses, and a LabVIEW-based software interface. This solution enables users to route any of 12 differential signal pairs to a single oscilloscope for analysis while seamlessly passing the others through. The result is a flexible, automated, and low-noise measurement system tailored for differential signal measurements.

The Challenge

Our test system needed to monitor 12 independent differential signals originating from a high-speed digital subsystem. Each signal pair carried sensitive timing and amplitude information, and all were required to maintain integrity during routing.

The three primary challenges were:

- Limited Oscilloscope Channels: The oscilloscope with the appropriate technical specification only supported two differential channels, far fewer than the 12 signals we needed to evaluate.

- Signal Integrity: Because the signals were differential, maintaining tight impedance matching and minimizing skew between the positive and negative legs was crucial.

- Automation Requirements: The test environment required fully automated control, eliminating manual reconnection of cables and ensuring repeatability across test runs.

This combination of constraints called for a custom, multiplexed routing solution—one that could dynamically connect any differential signal pair to the oscilloscope without degrading signal quality or requiring manual intervention.

Hardware Architecture

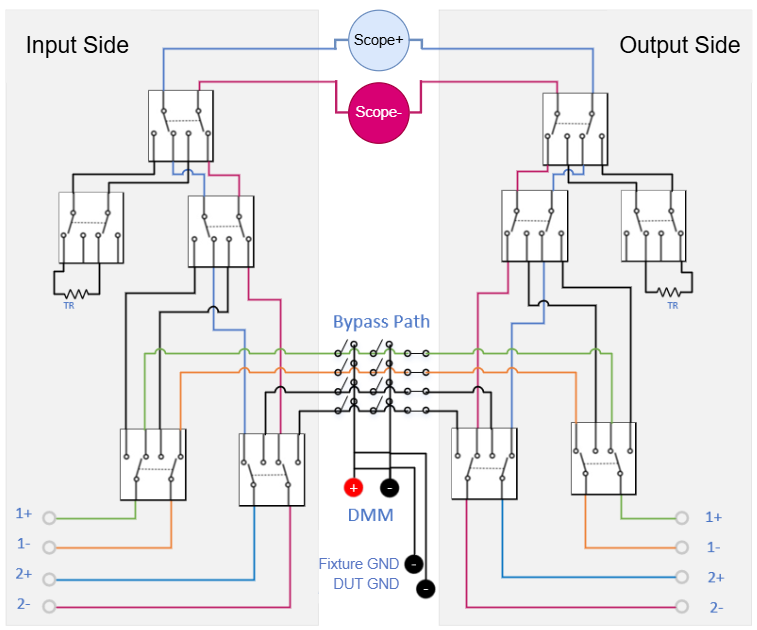

The foundation of our system is built with an NI PXI Chassis, PXIe switching cards, and an oscilloscope. The switching cards from NI and Pickering each contained a matrix of DPDT relays that are controlled using our custom LabVIEW application. Using DPDT relays was crucial for the design because each relay would link the positive and negative lines of each signal, ensuring that each signal’s switching was synchronized.

Signal Flow

- Input Selection Tree: The twelve differential signals enter and exit our test fixture through the same custom harness connector. Each signal has one set of positive and negative lines for the input, and one set of positive and negative lines for the output, for 4 in total. The input lines of the desired signal enter the Pickering relay card and pass through a series of relays to route to the oscilloscope, creating a selection tree. The remaining eleven signals bypass the tree and go through the bypass path, which can then be optionally connected to a DMM, test fixture ground, or DUT (Device Under Test) ground as desired.

- Oscilloscope Measurement: The desired signal to measure passes through a 2 channel PXI Oscilloscope. The first oscilloscope channel would measure the positive signal line and ground, and the second channel would measure between the negative signal line and ground. This allows the user to view the components of the differential signal individually or view the total output by creating a math channel.

- Output Selection Tree: Just like the input side of the tree, the signal is routed from the oscilloscope to the output side of the custom harness connector. This allows the signal to be used elsewhere as opposed to terminating within the test fixture. The symmetry of the system is also critical for maintaining signal integrity.

Each relay closure is software-controlled, allowing instantaneous switching between signals without physically altering connections. The process is automated, so a user only needs to select a signal to route, and all the associated relay states will automatically change to reflect this, instead of manually setting relay states.

Custom Cable Harness Design

A significant part of the project involved developing the custom cable harnesses that interfaced the DUT signals with the PXI cards and oscilloscope.

Because we were dealing with differential signals, cable symmetry and shielding were paramount. Each harness was constructed using shielded, twisted cables for each signal. This helped to reduce cross-talk between different signals in the harness. At the connection to the switch cards, several of the pins were shorted together, creating the paths among the different relays for the selection trees. Our harnesses also contained an internal resistor that could be used to terminate the signal after the oscilloscope, instead of routing it to the output. This could be used to simulate the presence of a different load on the output end if that hardware were not present.

Harness Concerns

- Input/Output Connectors: The harnesses utilized high signal integrity D38999 connectors for the signal input/output connectors to ensure the best possible signal integrity and compatibility without a DUT. The PXI connectors were 160-pin arrays that could connect all of the DPDT relay inputs and outputs, with plenty of space in the connector for internal pin-pin connections.

- Cable Routing: The cables were designed to minimize total length and bend as much as possible. Length and bending could have drastic effects on the signal integrity and could damage the internal wires.

- Shielding: All signals were routed using shielded, twisted cables. The shields were all tied together with a grounding screw to the shells of all connectors, where they would then make contact with the test fixture ground connection. This design ensured the most reliable signal integrity during later testing.

The result was a harness system that preserved the integrity of high-speed differential signals even through multiple routing layers.

Software Control with LabVIEW and Pickering Drivers

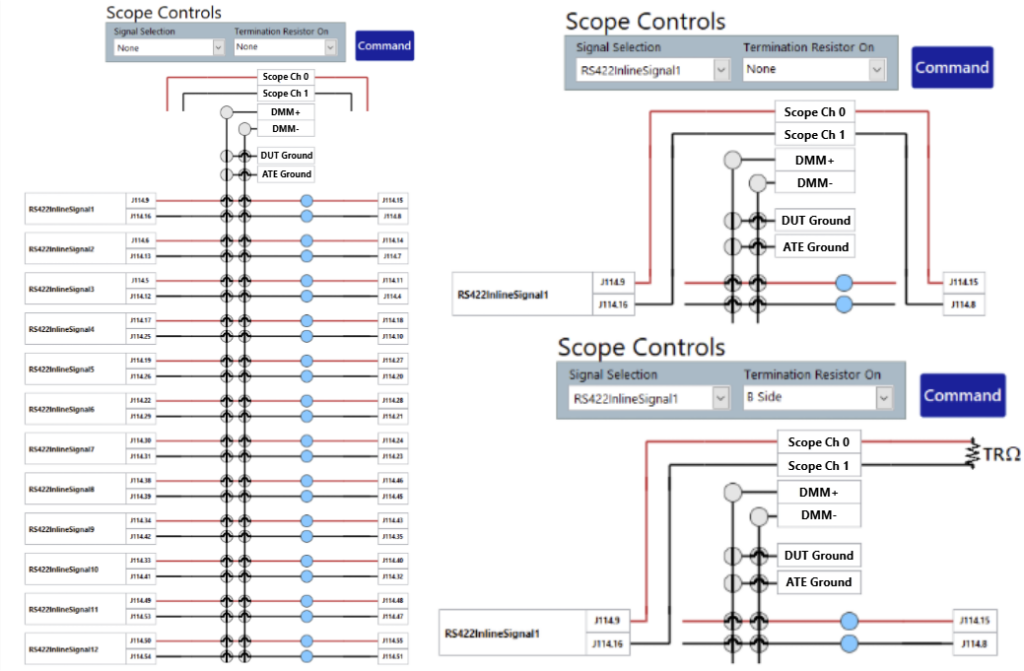

On the software side, we implemented the routing logic and user interface using a LabVIEW application. The app incorporates the Pickering pipx40 VISA driver library and the NI Switch library. Additionally, we created custom steps to be used in an automated TestStand sequence for automatic control within the LabVIEW application.

Signal Tree UI

The UI for the selection tree shows all 12 signal inputs/outputs, as well as connector and PIN numbers. Using the “Signal Selection” and “Terminating Resistor On” controls will route the intended signal through the tree and can also add the harness’s built-in terminating resistor if desired. The UI also provides a visual representation to the user. For signals passing through the bypass path, the two busses in the middle allow the user to connect individual lines to the DMM leads or the different system grounds.

Safety Features

The UI also has built-in safety controls to prevent short circuits from damaging sensitive hardware. The UI does not allow multiple signal pairs to be routed through the oscilloscope simultaneously. If a user attempts to connect a second signal, the first signal will first be disconnected from the oscilloscope, and the UI will update to reflect this. Additionally, the bypass path busses in the middle do not allow multiple items to connect to the same bus, as this could also lead to shorting different signal lines together.

Maintaining Differential Signal Integrity

One of the most critical aspects of the design was ensuring differential signal integrity through the entire multiplexing path. Switching and routing introduce potential sources of error such as impedance mismatch, crosstalk, and common-mode noise.

To minimize these effects, we implemented several design strategies:

- Matched Differential Paths: Both legs of each differential pair were routed symmetrically, including through the PXIe switch card traces. When viewing the oscilloscope measurements with terminating resistors, the data was noticeably more distorted than when routing symmetrically.

- Connector Pinouts: When designing the harnesses, the component selection was not the only important factor in signal integrity. The pin locations on the input and output connectors had a large effect. Placing the positive and negative lines of a signal too far apart created more crosstalk between different signals, so it was vital to place the positive and negative pins of each signal on adjacent pins. Conversely, it was important to keep the input pins far from the output pins. This would tend to create more uniformity between the positive and negative signals.

- Short Routing Paths: The layout minimized total signal length and avoided cable bends as much as possible. This puts less strain on the cable and increases signal integrity.

- Relay Selection: Pickering’s DPDT relays were chosen for their low insertion loss, excellent channel-to-channel isolation, and consistent contact resistance.

After assembly, the system was validated using a custom LabVIEW application for measuring signal integrity, with more info on that found here: Creating Eye Diagrams using LabVIEW Jitter Analysis.

Results and Performance

The completed system successfully allowed any of the 12 differential signals to be routed to the oscilloscope in under 100 MS, with no measurable degradation in signal amplitude or timing. Signal skew between differential lines was consistently below 10 PS, and insertion loss was negligible across the frequency range of interest.

Users reported significantly improved workflow efficiency, with no more manual re-cabling, reduced setup time, and fully automated test runs. The system has been integrated into both R&D and production environments, where it continues to provide reliable, flexible differential signal monitoring.

Lessons Learned

Developing a multiplexed oscilloscope system for differential signals highlighted several key insights:

- Signal Integrity Comes First – Hardware design decisions must prioritize impedance control and symmetry from the outset.

- Modular Design Simplifies Expansion – The PXI platform made it easy to expand from 8 to 12 channels by adding another matrix module.

- Software Flexibility Adds Value – The ability to automate and visualize routing in LabVIEW dramatically improved usability and test throughput.

Conclusion

By combining PXI hardware, precision cable design, and a LabVIEW control interface, we developed a custom oscilloscope multiplexing solution capable of routing 12 differential signals to a single measurement instrument. This approach preserved signal integrity, reduced manual intervention, and enabled fast and automated analysis of high-speed differential waveforms.

The system demonstrates how thoughtful integration of modular hardware and flexible software can overcome real-world measurement challenges. Whether used in validation labs or automated test stands, custom multiplexing architectures like this can extend the capabilities of existing oscilloscopes and simplify complex signal analysis tasks.

Ready to take your Test & Measurement project to the next level? Contact us today to learn more about our solutions and how we can help you achieve your goals.