The client required a single test platform capable of verifying the functionality of multiple power distribution unit (PDU) variants used in a modular battery pack design. Each PDU model featured different input/output configurations and test requirements, including power input limit testing, discrete signal verification, and hipot validation. The primary challenge was developing a test architecture flexible enough to handle these differences without needing separate test stations for each product.

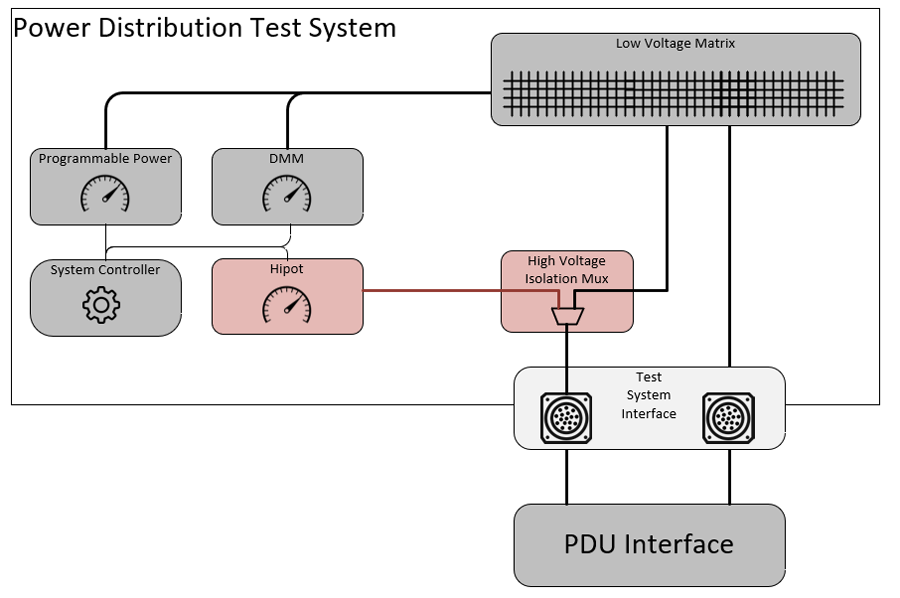

To address this, DMC engineered a reconfigurable switching architecture using a Pickering switch matrix and a Pickering high-voltage multiplexer. The switch matrix dynamically adapted the test system’s I/O configuration to match the specific PDU variant being tested, while the high-voltage multiplexer provided isolation for hipot testing. This configuration enabled safe, automated switching between low-voltage functional tests and high-voltage insulation tests without manual intervention.

The test fixture supported up to 20 device-under-test (DUT) pins, 12 of which provide hipot isolation, routed through the high-voltage multiplexer before connecting to the switch matrix. Functional test instruments, including programmable power supplies and DMM channels, were integrated within the matrix, simplifying signal routing and maximizing hardware reuse across different product types.

On the software side, DMC developed a custom test control application that empowered the client to define and manage their own test specifications and functional sequences. The system also featured MES integration, enabling automatic test selection based on the scanned serial number of each PDU. This ensured that the correct test sequence was executed for every unit and maintained complete production traceability.

By combining modular hardware design with configurable test software, DMC delivered a flexible, future-proof EOL test solution that simplified production operations and reduced testing complexity across the client’s PDU product family.

Learn more about DMC’s Test & Measurement expertise and contact us for your next project.