DMC sent five engineers to the Inductive Community Conference (ICC) on September 16–18 in Sacramento, CA. It was a great opportunity to catch up on the latest technology trends, real-world use cases, partner demos, and product roadmaps in the Ignition ecosystem. While there, I co-presented with an engineer from one of our clients, Sila Nanotechnologies, on a challenge many manufacturers face: how to scale without chaos. The session was a chance to share lessons learned not only from our work with Sila, but also from DMC’s broader experience helping customers grow their operations. Below is a summary of some of the key points from our presentation.

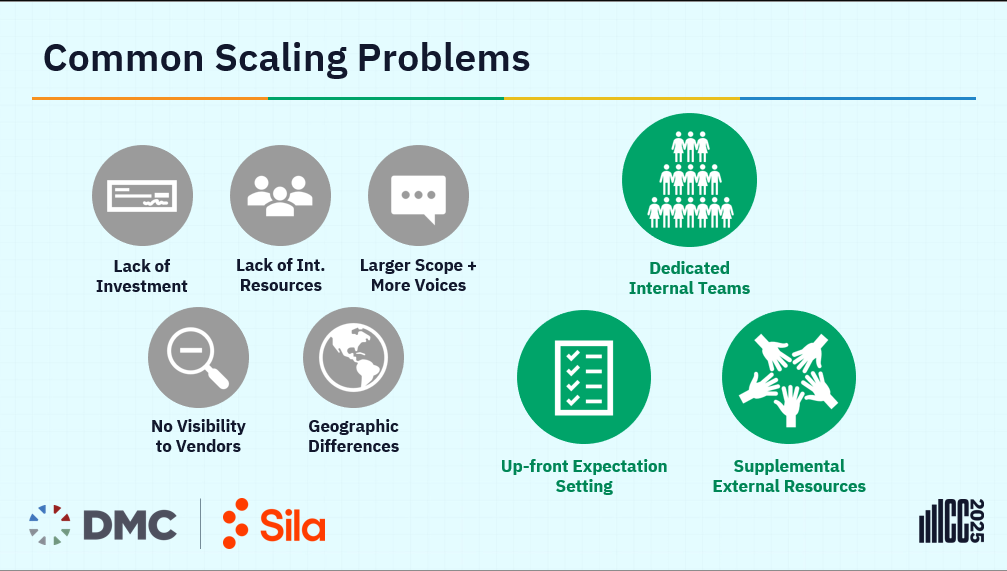

Common Program Level Scaling Problems and Solutions

From an integrator’s perspective, the challenges companies face when scaling their operations tend to repeat:

- Lack of investment early: Doing the bare minimum to get running might work for a pilot, but it creates real pain when scaling to full production.

- Lack of internal resources: Controls engineers are commonly stretched thin fighting fires, leaving little bandwidth for big-picture design.

- More voices, more complexity: Larger operations mean more voices in the room. Customers end up working with EPCs, OEMs, integrators, and other 3rd party contractors — the larger the scope, the harder it is to stay aligned.

- Limited vendor visibility: Even with strong internal controls standards, if you don’t have visibility into how OEMs are completing their projects, new machines can drop onto your plant floor that your internal team won’t be able to support.

- Geographic spread: New plants in different time zones introduce communication and localization challenges.

These problems are real — but they’re also solvable. We highlighted a few key strategies that help companies overcome these challenges and scale more effectively:

- Dedicated internal teams: Separating plant support from new plant development frees resources to focus on architecture-level design.

- Up-front expectation setting. Clear communication of controls standards and architectures early on ensures alignment across internal teams, integrators, and OEMs.

- Supplemental external resources: Partners like DMC can provide local support and scale up quickly, freeing internal engineers to focus on the higher-level problems only they can solve.

Companies that invest in these approaches early tend to scale smarter, faster, and with fewer surprises.

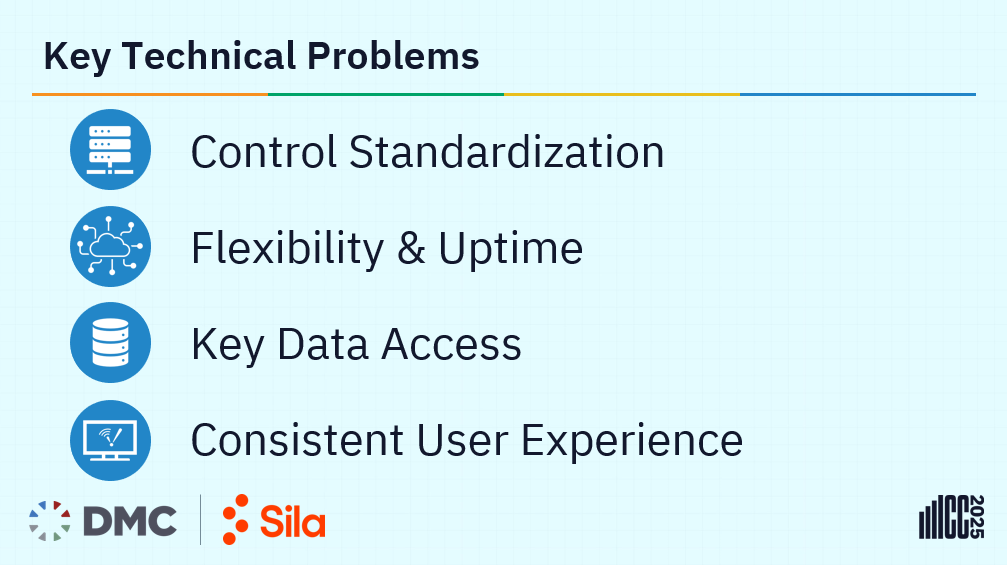

The Technical Backbone: MQTT + UDTs + Structured Data

While program-level issues matter, technical architecture is equally critical. Our presentation walked through how MQTT and standardized UDTs can form a flexible, resilient backbone:

- Standardized UDTs: Define tags in a consistent hierarchy and structure so that all systems “speak the same language.”

- MQTT as transport: Instead of point-to-point gateway connections, devices publish once to a central MQTT broker. Consumers subscribe as needed, making onboarding fast and keeping systems resilient.

- Structured data backbone: Together, UDTs and MQTT enable a model where:

- Data is published once, consumed many times.

- Access is democratized — different systems, from cloud data lakes to custom trending software, are able to access the same data without friction.

- Context is understood by all parties, because it is consistent across the site.

- Data is real-time. Key parameters are live, not batched, enabling faster decisions.

Consistent User Experience

We also emphasized user experience as a critical piece of scale. With Ignition Edge and central Gateway deployment pipelines, companies can:

- Deploy shared screen libraries via global projects to ensure a consistent look and feel across OEM and internally developed tools.

- Use session properties so the same screens adapt whether running locally or remotely.

- Utilize Enterprise Administration Module to push entire projects to the edge to ensure consistency from control room to edge HMI

Operators and engineers benefit from a common interface across systems, which reduces training time and builds trust in the system.

Why This Matters

At DMC, one of our values is “Make Things Happen.” That means helping clients not only solve today’s challenges, but also laying the foundation for sustainable growth.

The strategies and architectures we presented at ICC — tackling scaling problems head-on, leveraging standardized UDTs, using MQTT as a flexible backbone, and delivering a consistent user experience — show that scaling doesn’t have to be chaotic.

When done right, scaling becomes predictable, consistent, and repeatable. The foundation built here supports not just this scale-out, but future expansions for years to come.

Ready to take your Automation project to the next level? Contact us today to learn more about our solutions and how we can help you achieve your goals.