DMC utilized our MQTT driver to connect the customer’s PLC to a broker running on the AWS server. The driver sends and receives data directly between the PLC and AWS servers, giving the framework for monitoring and control of systems in the field.

We then developed a broker and API that communicated the relevant information from the MQTT driver to the correct location in the cloud database. The MQTT messages were received in the cloud by the broker service, which parsed data and sent it on to the API. The API connected with our SQL cloud database to communicate information in and out of the database.

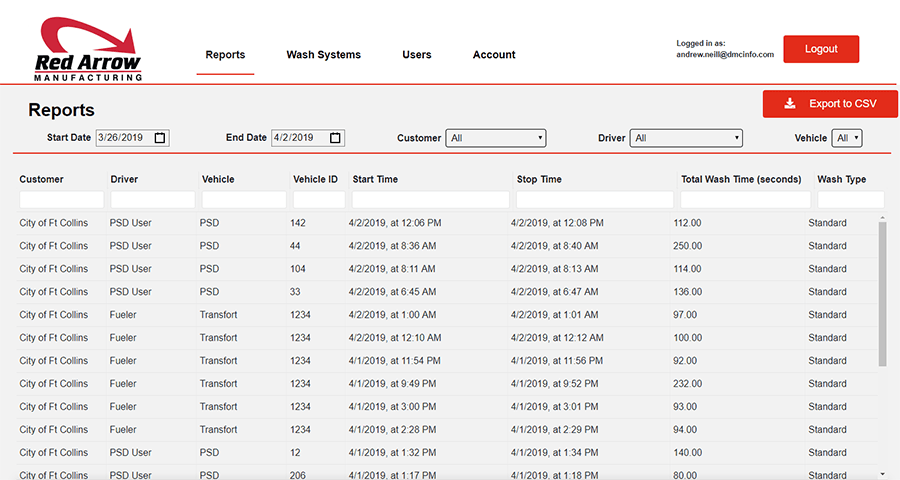

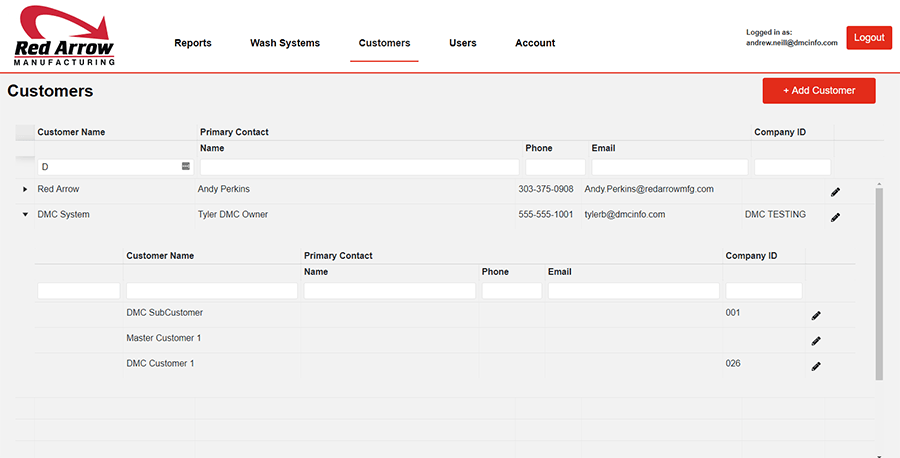

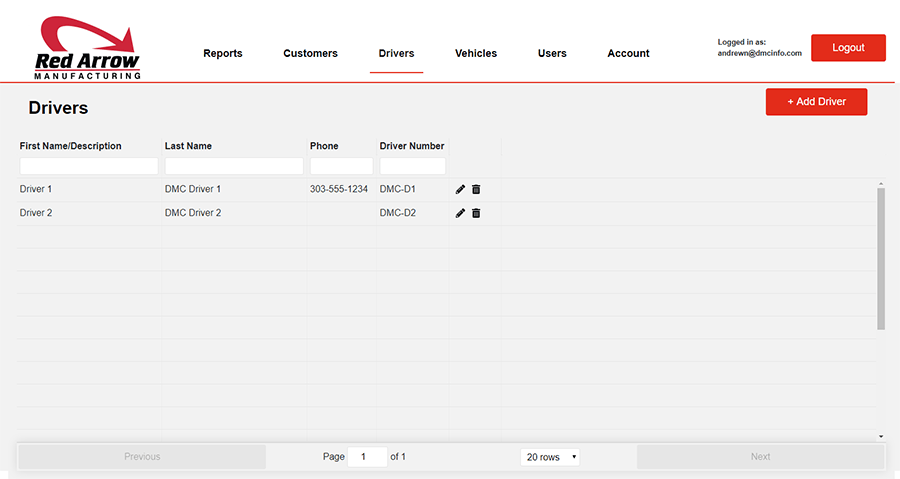

DMC built a custom REACT website to display the data and add vehicles and drivers, as well as control the wash system. End-users can see tables that contain wash event data, vehicles, users, and drivers. Red Arrow can also use the website to manage the end-users, wash systems, and view global data. All data can be added and edited in the tables, except for the wash event data. Users can also edit their personal data.

DMC is continuing to work with Red Arrow to add additional functionality for end-user convenience and increased overall productivity and automation, including RFID scanning and more advanced control. Red Arrow continues to come back to DMC for work due to the complexity and success of the system. The upcoming wash system control page allows the user to enable and disable the wash system, schedule times when the wash can be on, and provide feedback of tank levels, connectivity status, and connection information.

Contact DMC for more information regarding our PLC Programming services or Web Application Development expertise.