DMC brings decades of proven expertise in PLC programming and industrial automation, delivering tailored solutions that harness the full potential of Programmable Logic Controllers (PLCs). Our highly skilled PLC programmers specialize in developing robust, efficient, and scalable industrial PLC systems from the ground up. Whether launching a new automation initiative or seeking to modernize or upgrade an existing PLC system, DMC has the technical depth and industry knowledge to meet your goals. We support a wide range of PLC platforms and work across diverse industries to deliver innovative, reliable, and cost-effective automation solutions.

Platform Expertise

Our team of PLC programming experts support a wide variety of platforms including, but not limited to:

Ready to start your next PLC Programming project? We can help.

We work with all common industrial networking protocols including PROFINET, Ethernet I/P, EtherCAT, PROFIBUS, AS-i, DeviceNet, Modbus RTU, Modbus TCP, RS-232, RS-485, SERCOS, CAN, and others).

DMC also provides expertise in Process and Machine Safety, performing safety assessments, programming failsafe PLCs with safety I/O, safety device integration, and failsafe communication protocols.

In addition to PLC programming, we also develop software libraries, APIs, AOIs, and function blocks that enable end users to easily integrate our clients’ hardware products into a PLC platform.

Seamless Integration

DMC can seamlessly integrate PLC controls systems with the rest of your plant.

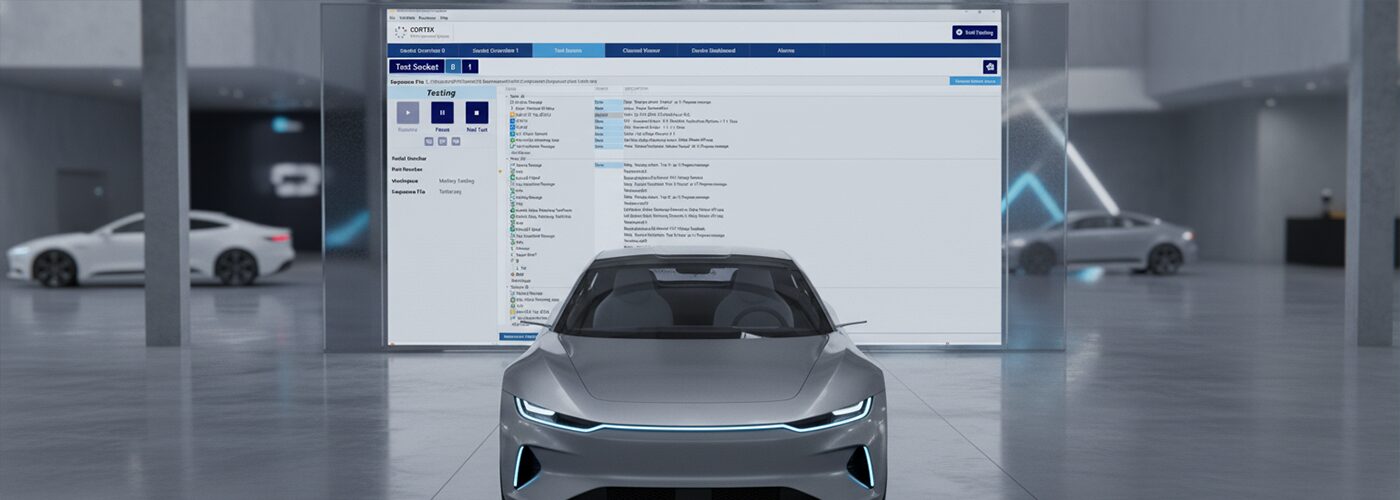

DMC’s PLC Solutions

DMC develops new Programmable Logic Controller solutions from start to finish, including functional specification development, offline programming, and onsite commissioning. We offer simulation and virtual commissioning services to optimize startup time. DMC consults on automation component selection, assists in programming standards development, and provides training for our clients. PLC Solutions our team provides include:

Motion Control & Servo Systems

Continuous and Batch Process Control

Discrete Manufacturing, Packaging, and Heavy Machinery

Material Handling and Storage Systems

Specialty Processes and Equipment

DMC works with manufacturers to provide plant-wide and line-level programming solutions. We work with OEMs and custom machine builders to provide expert programming for their equipment. DMC also provides consulting between manufacturers and their OEMs to ensure optimal interoperability.

DMC’s Software Approach

We focus on well-designed, structured, and modular PLC code appropriate for any factory. Our reusable code utilizes UDTs and class-based architectures to follow appropriate industry best practices, such as ISA-95 and PackML, and adheres to IEC 61131-3 standards for ladder, structured text, function block diagram, and sequential flow chart development.

We use our internal libraries of reusable code to help reduce development cost and minimize commissioning time. The end result is a flexible system that is easier to understand, debug, and modify for future needs.

Our PLC Programming Team

DMC has one of the largest teams of automation engineers in the US allowing us to take on large projects, even on short notice. We can quickly ramp up by working as an extension of your internal team and, with offices from coast to coast, provide the local onsite support you need.