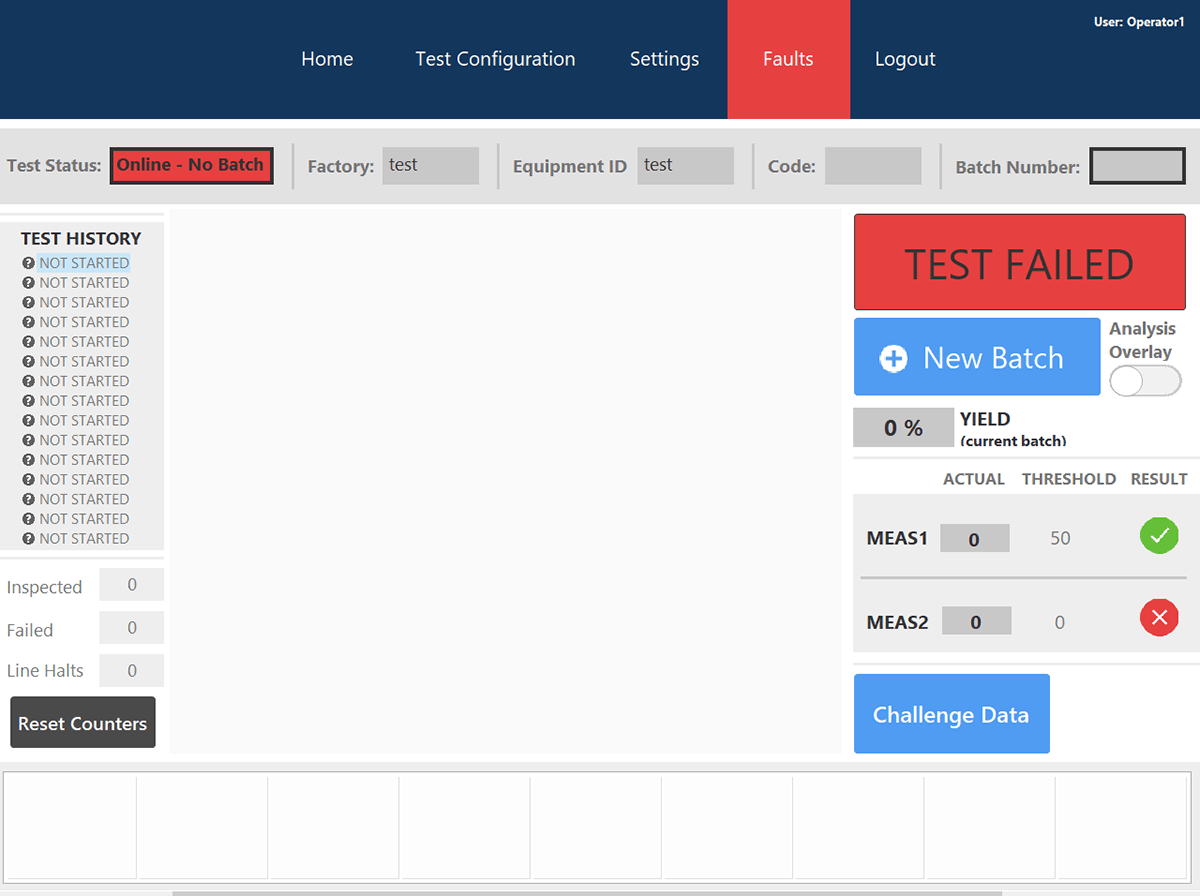

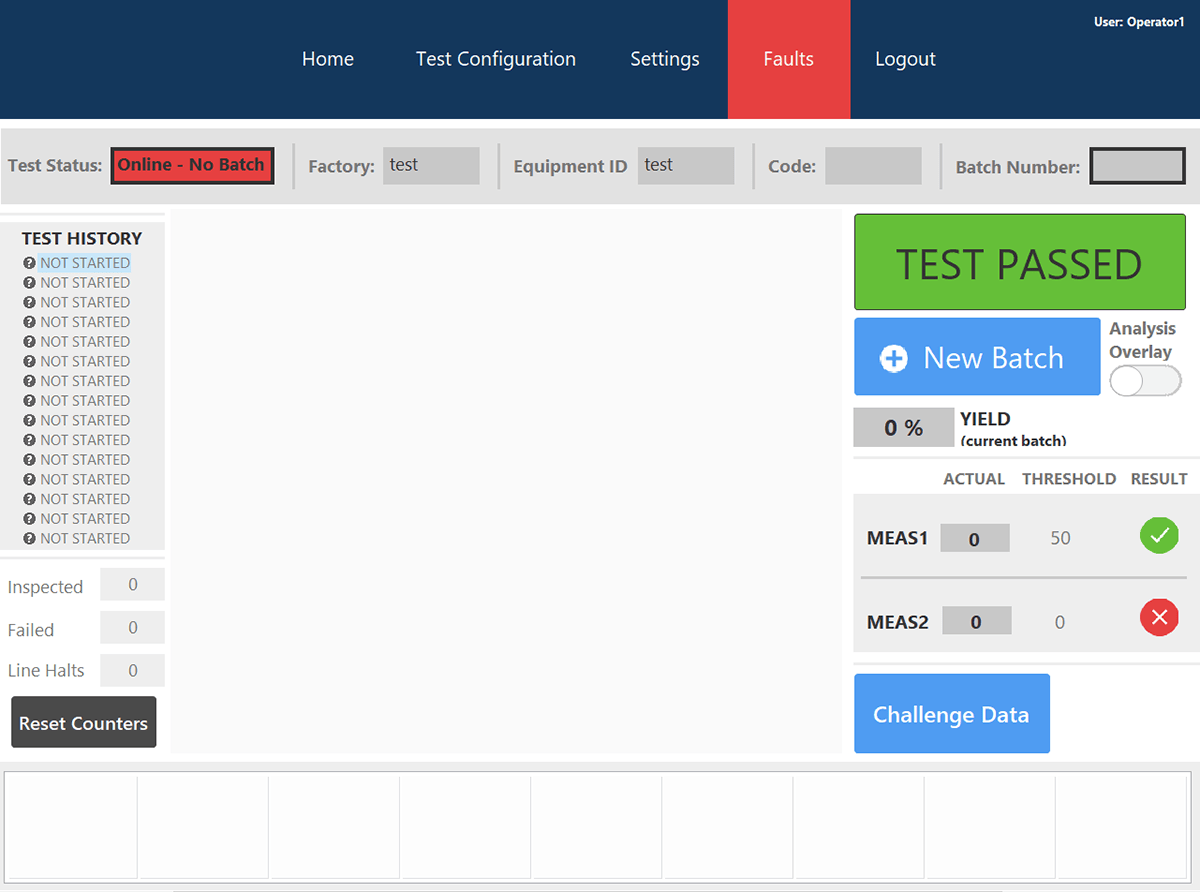

End-of-line inspection is necessary for the client's production lines to ensure that any product not up to their quality standards is rejected. This is a particularly important concern in the healthcare industry. The vision inspection system employs a proprietary camera in conjunction with National Instrument's IMAQdx to acquire images of the filled IV bags. The DMC application then utilizes the client’s algorithm to determine if a bag passes or fails inspection based on key pixel measurements and thresholds.

System Update

The client's prototyped application ran purely on Windows. In the migrated and updated system, a National Instruments Industrial Controller (IC-3173) runs a LabVIEW Real-Time and FPGA Application that controls the acquisition process, performs the analysis, and communicates results with both the line control PLC and a PC HMI Application. The HMI Application, also written in LabVIEW, is displayed on a touch-screen to the operator, allowing them to oversee the inspection process and configure key parameters. The Real-Time Application operates independently from the HMI, so that after beginning a test, the inspection can continue running without the HMI Application running and without being monitored by an operator.

System Parameters

This application utilizes several levels of system parameters which allow the system to be re-configured for different products, production lines, and environments through the HMI. Machine-level system parameters are stored locally and specific to the machine and production line. Product-level system parameters are stored in a database and specific to the type of product being inspected. The parameters accessible to each user are restricted by their user access level.

Alarm Handling

These applications employ DMC's LabVIEW Alarm Handling Toolkit which is used to respond to both predicted and un-predicted system faults across the Windows, RT, and FPGA systems. All alarm data is compiled, and relevant information is displayed to the user for informational and diagnostic purposes. Based on the severity level of alarms present, the application automatically performs configured actions to ensure that the system is put into an appropriate operating state. For example, informational alarms result in an extra pop-up to the user while more severe alarms immediately signal the PLC to stop because the inspection system is down.

Data Logging

All test data is logged to a database through a Web API Database. To ensure data integrity, if the system loses connection to the Web API, the data is logged locally using SQLite with a LabVIEW driver. Once a connection is reestablished, the data in the SQLite file is pushed to the database. The system also provides the option to enable local TDMS logging.

Learn more about DMC's partnership with National Instruments.