Our client, the Sanitary District of Michigan City, Indiana, runs a large operation that is responsible for wastewater treatment, sewer maintenance, and other related services. They reached out to DMC for help with their wastewater treatment plant and its outdated data acquisition and monitoring system. They were using a Wonderware InTouch HMI application for many years, but it didn’t have the reliability, accessibility, and control they were looking for.

DMC has implemented hundreds of HMI & SCADA solutions for our clients in many industries, so we were well equipped to take on this project. We began by taking a full account of their existing system. We reviewed their application to define the data, map its sources, see how they currently visualized the data, etc.

Once we finished our review and their server infrastructure was set up for the new SCADA system, we started our design phase. An important goal of our client was for this new application to be accessible on the go by maintenance personnel and to be displayed on a large video wall in their main operations room. We accomplished both by leveraging AVEVA’s scalable Industrial Graphics to develop applications that can be used from any device, from their large video wall down to a mobile phone with AVEVA InTouch HMI Access Anywhere. With this range of capabilities, the plant’s systems can be easily and closely monitored from inside and outside the facility.

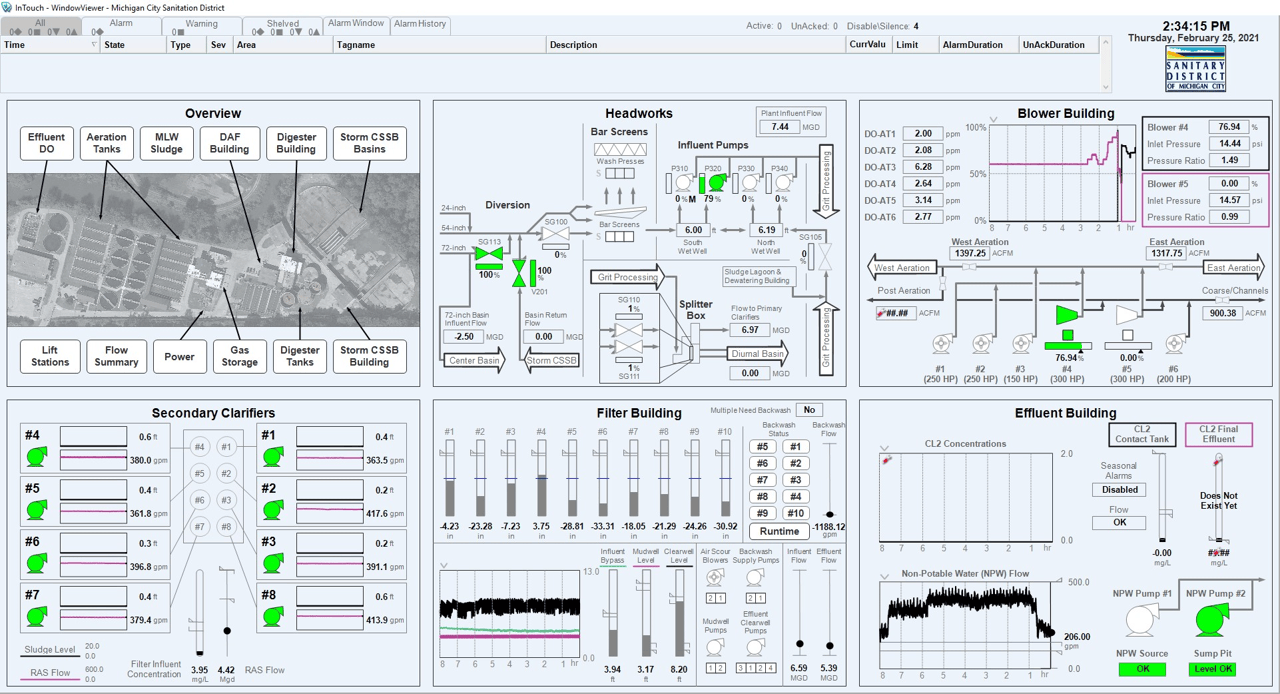

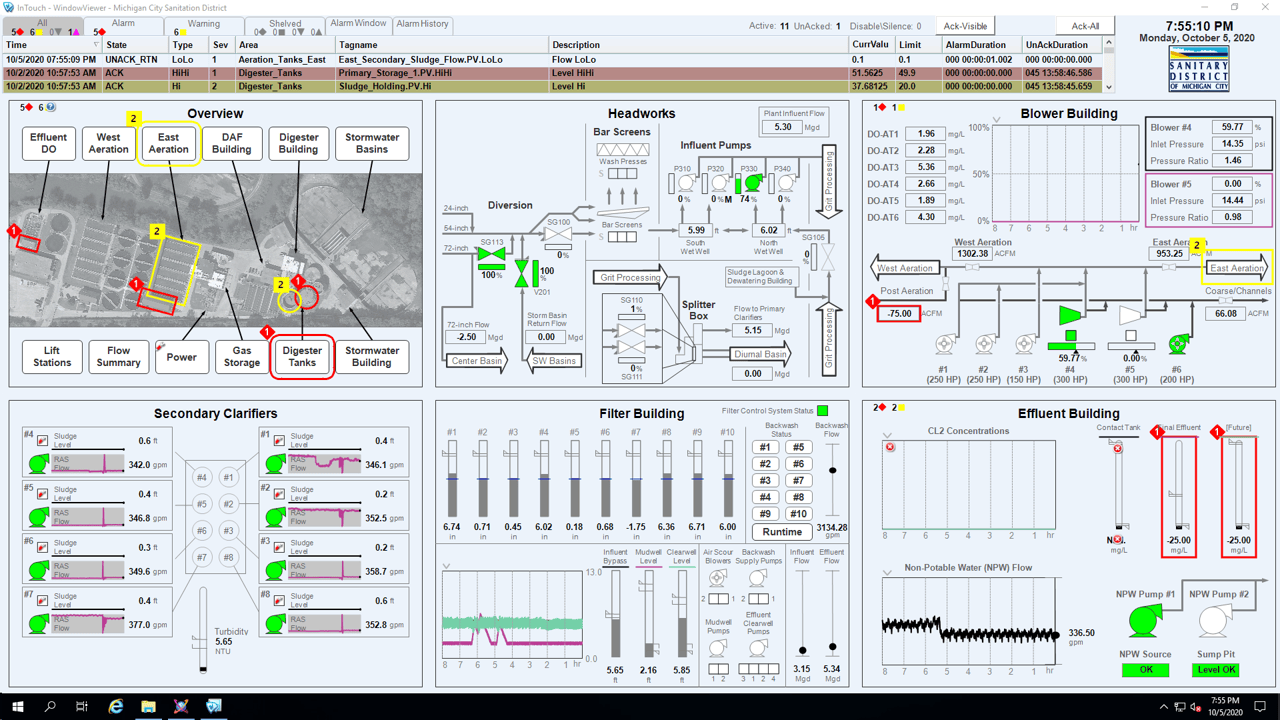

We utilized the AVEVA Situational Awareness Symbols Library to implement the best practices of a high-performance HMI. This included the use of alarm borders and a simple color scheme, allowing operators to quickly identify which systems need attention. In addition, meters & historical trends were added throughout the application to show data in context, allowing operators to analyze and recognize conditions before they become alarm situations. On the back end of the system, all data is retrieved from the PLCs using redundant Application Servers (with automatic failover). Data is stored to an on-premise AVEVA Historian server, which is easily accessible to the operations team through AVEVA Historian Client Web for ad-hoc trending and analysis.

Screenshot of HMI with all systems working properly

Screenshot of HMI with various alerts and alarms going off

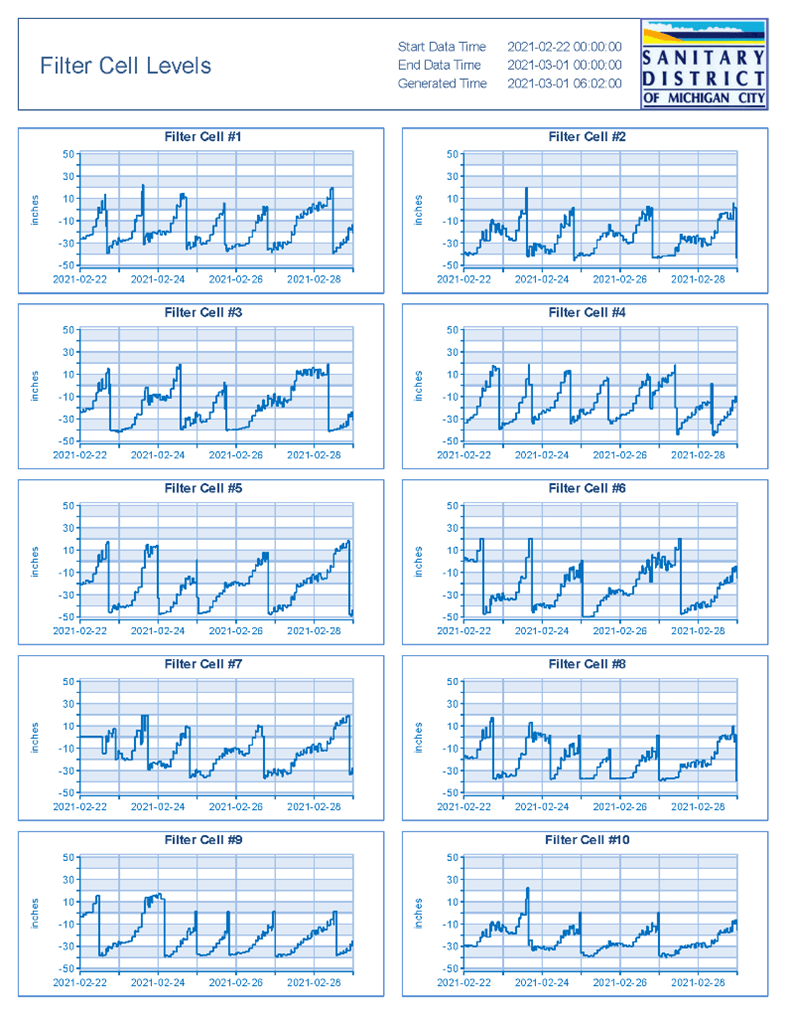

To further automate and streamline their processes, we integrated Dream Report into the SCADA solution. This software retrieves data from the AVEVA Historian to generate periodic and on-demand reports on system performance and for regulatory compliance, and delivers those reports to stakeholders automatically via a web portal and direct to their email inboxes.

Screenshot of a generated report

With DMC’s wide range of manufacturing automation expertise, our team was able to understand our client’s entire operation. This allowed us to deliver a solution that is fully integrated, easy to operate, and can grow with our client as their needs change.

Learn more about other HMI & SCADA solutions DMC has delivered to clients and contact us to get started on your next project.