A client in the automotive industry selected DMC to develop an end-of-line (EOL) functional test system for a drivetrain Electronic Control Unit. The test included flashing firmware and testing the inputs, outputs, and internal states of the ECU. Testing necessitated simulating loads for the ECU outputs as well as precise simulation of a variety of sensor signals for the ECU inputs. Controller area network (CAN) communication was used in conjunction with the simulated I/O to configure the ECU for different test steps and read back internal data.

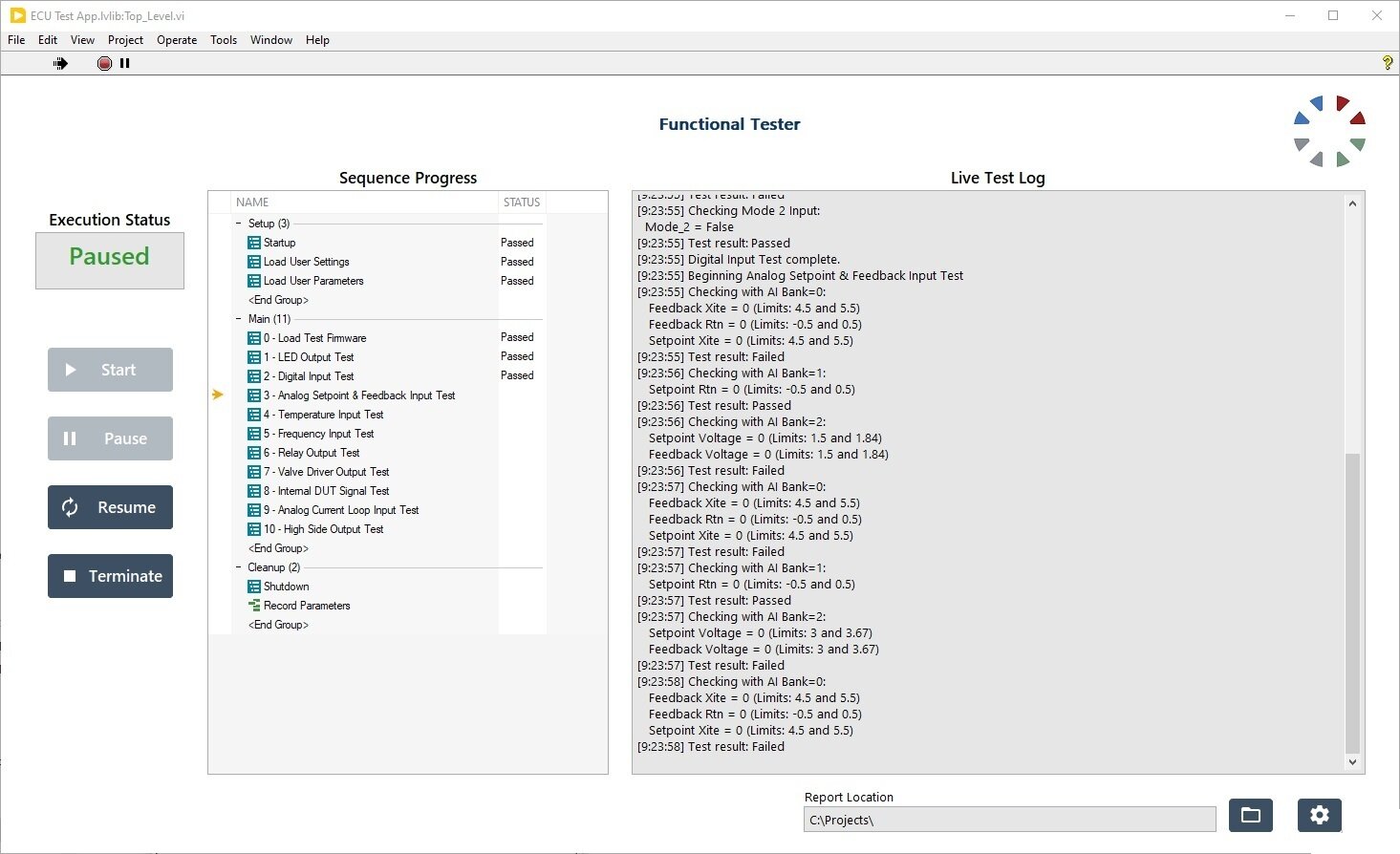

The software design took advantage of the flexibility of NI LabVIEW to abstract the CompactDAQ hardware. NI TestStand was used for test sequencing, pass/fail determination, and to automate report generation. LabVIEW was used again for the User Interface, providing an intuitive and easy to use interface for operators and engineers alike. This combination allowed us to minimize software development time while leveraging world class development tools to simplify future maintenance and upgrades.

We began by working with the client to define requirements and identify useful features. Once the preliminary hardware and mechanical designs were complete and the software architecture was selected, we held a Critical Design Review with the client. This, along with bench testing of the ECUs at DMC, confirmed our design direction and validated our assumptions, allowing completion of the design and minimizing the potential for issues and delays.

Early in the project we worked with the client to develop the requirements and details of the acceptance testing plan. Once the software development and hardware build were completed, we worked side-by-side with the client to complete acceptance testing. Delivery included extensive documentation including full schematics and source code. We can also provide in-depth training and ongoing support.

DMC’s expertise in EOL testing and automotive ECUs allowed us to deliver a robust solution quickly while meeting or exceeding customer requirements and expectations.

Learn more about our Battery pack and BMS Test Systems and contact us today for your next project.