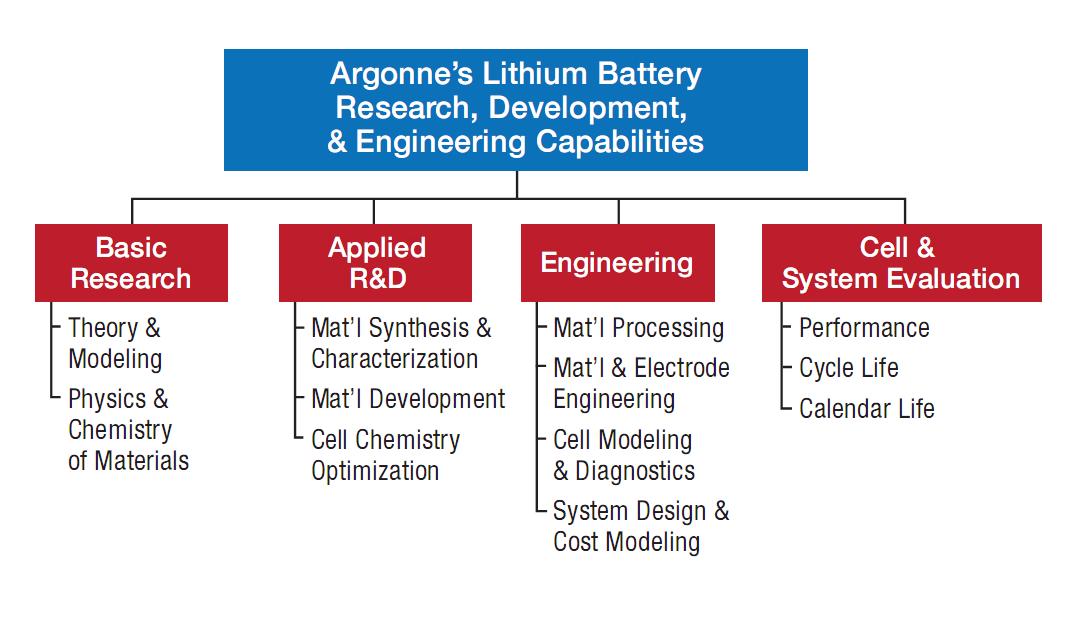

DMC collaborated with the engineering staff of the Argonne National Laboratory Electrochemical Analysis and Diagnostics Laboratory (EADL) to define hardware and software specifications to meet their requirement for a fully configurable battery testing platform with an integrated laboratory safety monitoring system. The system specifications required a highly flexible platform capable of producing consistent test results. The system also implemented a variety of test fixture hardware and data acquisition instruments. To address the demand for flexibility, DMC architected a custom Distributed Test Software Platform that utilizes the benefits of both Real-Time and Windows environments.

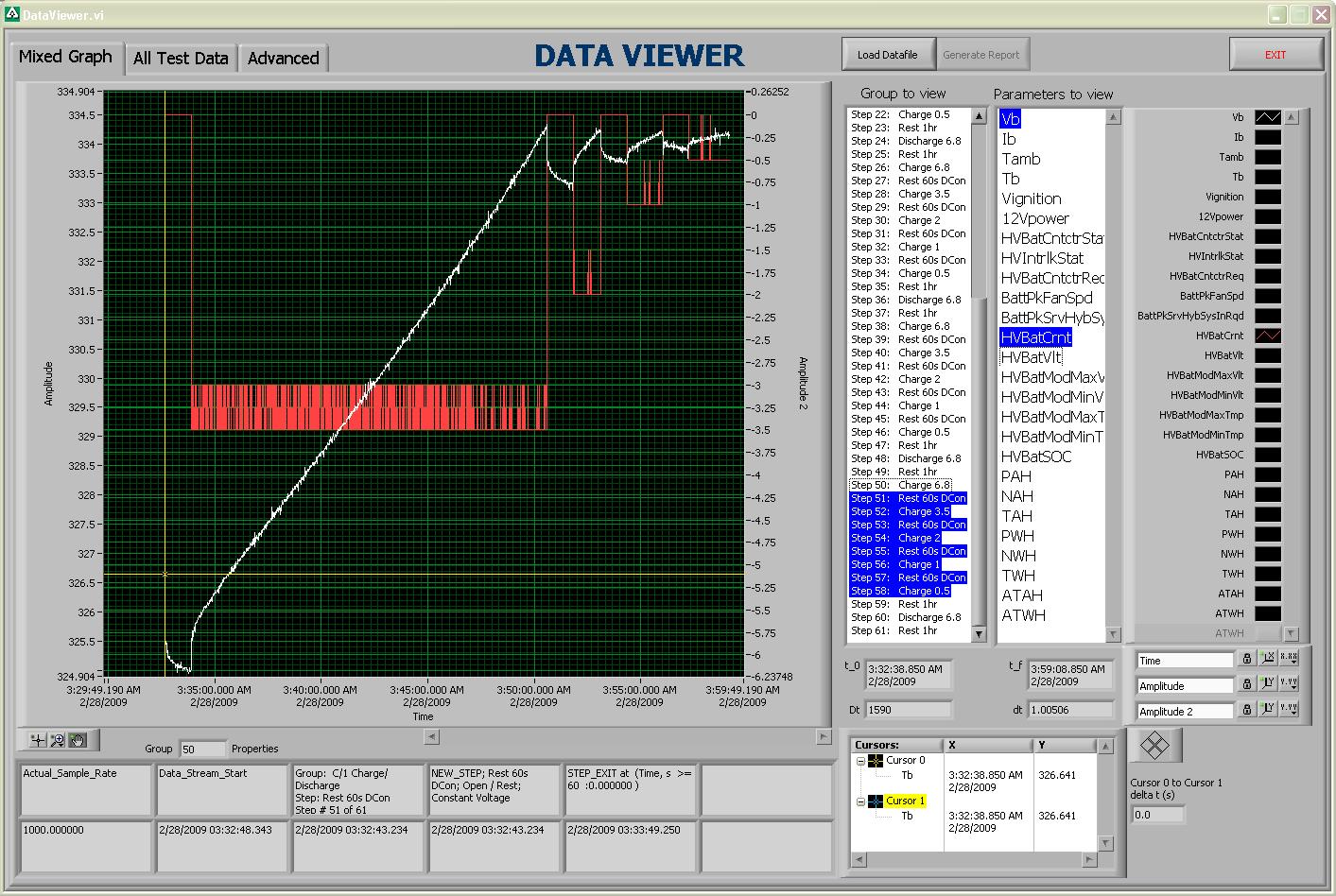

Software for battery test execution was programmed in LabVIEW for Real-Time to capitalize on deterministic performance and stand-alone reliability. A PXI chassis with a Real-Time operating system provides critical control logic and data acquisition. Each chassis is capable of running 10 asynchronous tests for 1000 hours or more. The test chassis are on a local network, and store data to a central file server running an MS Windows Server and an SQL Server. Any test on the system can be configured, controlled, and monitored from any PC on the network. The custom Test Interface features the ability to define test steps, configure modular hardware, access a Battery Information database, and monitor live test conditions. Raw data is stored in a TDMS format and is viewable through a custom data viewer and NI DIAdem.

Battery and Fuel Cell test environments can present significant safety concerns. A lab-wide safety system consists of independent, highly available cRIO devices that monitor lab conditions and are capable of automatically shutting down tests in case of hazardous lab conditions. This functionality is achieved with LabVIEW for Real-Time and for FPGA.

The system provides a modular, scalable, and fully configurable test platform, allowing the engineers and scientists at Argonne to accommodate and accurately test a wider variety of energy storage devices. The high level of flexibility delivers precise test results without requiring the use of any one specific battery cycler hardware device.

Learn more about DMC’s Test & Measurement Automation expertise and contact us for your next project.