DMC was approached to develop a centralized database reporting and trending system for a company in the manufacturing industry. DMC began by installing and configuring Siemens Process Historian and Information Server on two of the customer’s servers.

The installation process for Siemens Process Historian requires careful selection of file locations and user permissions. As an advanced and complicated database, accessing all of the needed data stored in Process Historian’s SQL database required some reverse engineering from DMC. Once the Process Historian was running, we imported a copy of the database into one of our DMC’s own SQL servers for development. DMC also optimized the speed of database queries to improve overall efficiency and enable real-time reporting.

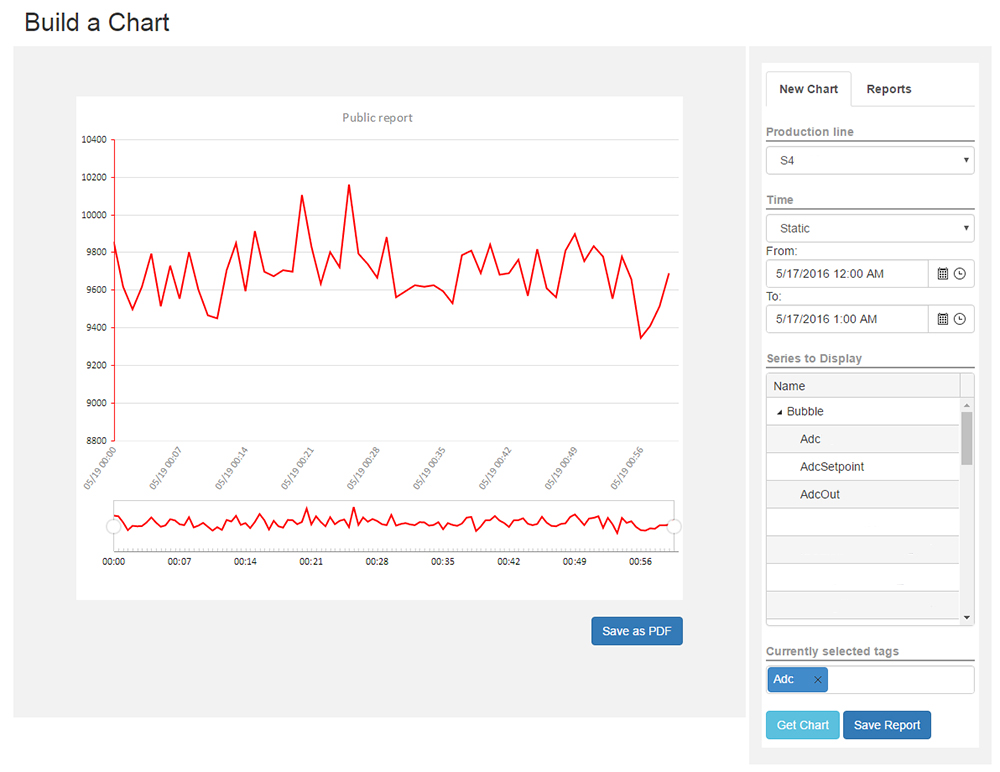

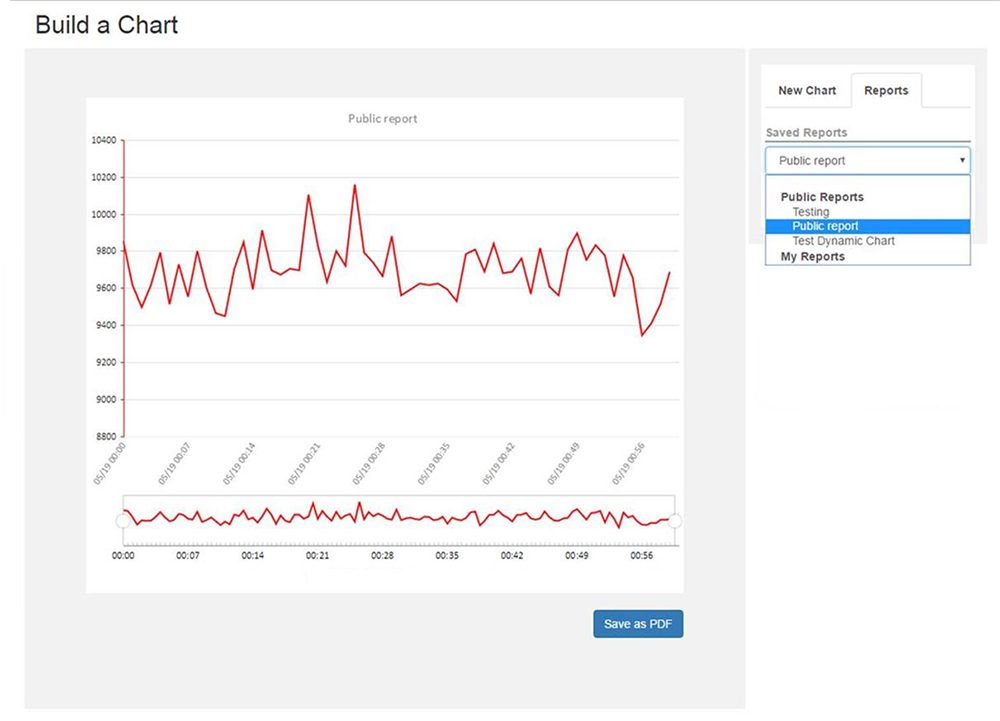

The data is displayed as live trends, past trends, and reports on a custom website built with C#. Custom charts were created based on Telerik’s ASP.NET AJAX controls, which enables the customer to interact with the data via pan and zoom features for easier data exploration. A personalized dashboard page was created to allow each user to save a set of preconfigured reports to their dashboard. This allows much quicker access to frequently used reports and enables easier configuration.

DMC completed the entire project by working through a remote desktop-type application and collaborating with the customer’s internal staff. DMC also provided training and documentation on configuring WinCC computers and creating reports in Information Server to enable the customer to make changes with little to no assistance from DMC.

Learn more about DMC’s Manufacturing Execution Systems (MES) expertise.

Learn more about DMC’s Application Development expertise and contact us today for your next project.