DMC’s solution leveraged different DEWETRON hardware platforms and a custom LabVIEW software application to create the blender test carts. The carts are approximately kitchen counter height, with an E-Stop at the top for ease of use in the customer’s lab. The blender under test can sit either atop the rack or next to it, with the entire cart controllable from a laptop. The cart was built to the specifications of several models of blenders, allowing switching between 2- and 4-pole motors as well as different amperage ranges up to 20A, with a design in place for a 50A version as needed. The cart is on casters, allowing it to be easily rolled around the lab to different locations, and the test configuration allows different channel setups, data limits, and displays to accommodate testing needs across the facility.

Figure 2 DEWETRON TRIONet3

Figure 3 DEWETRON XR Modules

Figure 4 One of the Completed Test Carts with a Blender on Top

DMC is also a long-standing NI partner, and we leveraged our deep LabVIEW programming experience on this project to deliver a high- quality solution.

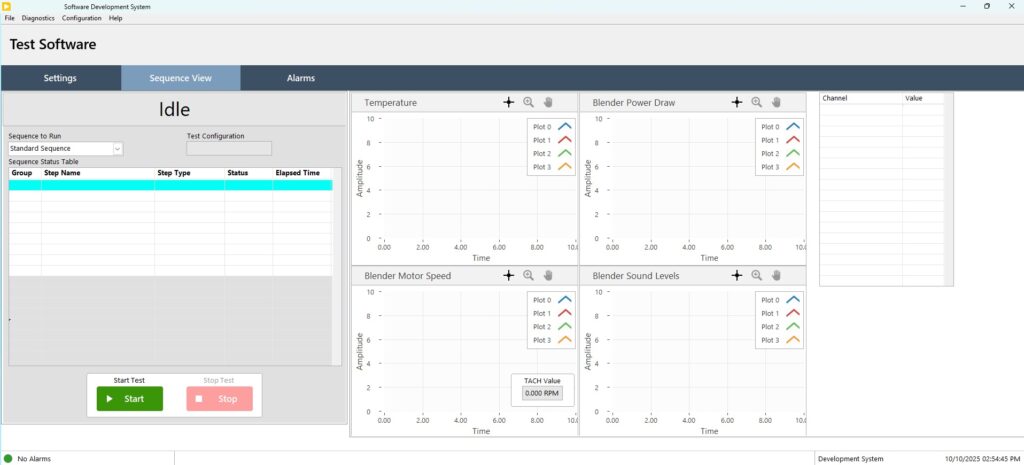

The cart measures current, voltage, speed, and temperature, and displays them appropriately on the custom user interface. As a sequence is running, the UI shows the progress in addition to the live data. There’s a separate tab for viewing any alarms, such as application errors, e-stops, or out-of-range values, using DMC’s Alarm Handling toolkit.

There’s also a tab for customized settings, where the customer can specify the units, scaling, and type for each physical channel in the system, depending on what unit they’re testing.

Figure 5 A View of the Test Software with Sequence Monitoring, Data Plots, and a Live Data Table View

Conclusion

DMC’s expertise in a variety of hardware and software platforms made us a great fit for this consumer goods test system, and we’re always looking to do more. Our customer was pleased with how easy it was to switch over to the new test carts,and is excited about adding new features and expanding, already given the system’s flexibility for upgrades. Every product is different, and balancing streamlined features and maintainability with customization and expandability is a challenge DMC is always up for.

Learn more about DMC’s Test & Measurement consumer goods test system expertise and contact us for your next project!