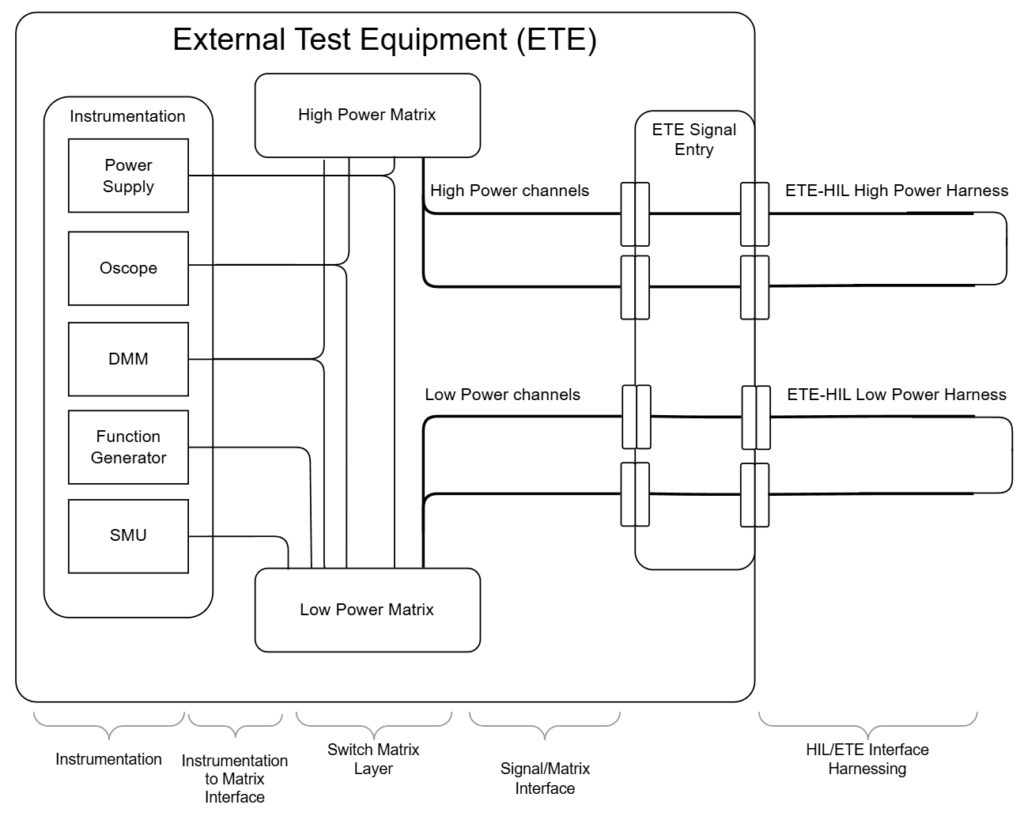

The External Test Equipment (ETE) system serves to validate every signal in the client’s hardware in the loop (HIL) test systems. The ETE exists as a separate, self-contained rack of hardware; it contains a number of sourcing and measuring instruments capable of checking out all of the HIL’s circuit type implementations, and these devices can be routed to all test points via large switch matrices which are the foundation of the rack’s Helix SwitchCore platform. Using this platform architecture, the ETE can simulate a control unit that is sourcing or responding to signals like the actual UUT will.

The ETE is designed to maximize flexibility for future testing of the existing HIL racks, as well as potential iterations of HIL design. It can be used as a validation tool and a general purpose debugging tool. The mass interface connectors route all input signals through configurable switch matrices to provide a connection path from every input pin to any connector on rack measurement instrumentation. The ETE system includes a PC that acts as an interface between PLANT software and rack-mounted measurement instrumentation; the main ETE application is a Python-based REST API that runs headless and does not require an external monitor. This application integrates easily with existing customer test executive software and enables the test developer to control all ETE devices as if they were operating a single unified instrument.

Self-Test Capabilities

In addition to validating HIL racks, the ETE has the capability of validating itself. This is performed by using DMC’s automated self-test sequence which can verify all 2,000+ channels are wired properly and all instruments are functional for testing.

Software Safety Rules

The ETE has software enforced safety rules that limit the duration of power sourcing instruments, number of connections between power sourcing instruments and signal lines, and signal routing limits for overcurrent protection of switching lines.

It is important to note that these software safety rules are supplemental to the system’s hardware controlled safety circuit for E-stop integration.

Built In-House

DMC’s internal Fabrication team built the ETE test system in-house. The system consists of a 24U rack system on heavy duty caster wheels which allows the system to easily move throughout the client’s testing facility. The system PC and switching hardware occupy the bottom half of the rack and measurement and power sourcing instrumentation are installed in the front, top half of the rack. The back of the rack has mass interconnects to connect to HIL racks or loop back to itself for self-test.

Custom Configurations and Scalability for Any Test System

The ETE can be expanded further to contain additional hardware to broaden test scope and allow additional channels, higher power tests, and support for more UUT functions. The modular rack design allows flexibility to scale up (or down) DUT channel count and testing functions in order to meet evolving test requirements.

Conclusion

DMC’s Helix SwitchCore hardware platform paired with the REST API software architecture gives the External Test Equipment (ETE) rack the capability to validate high signal count hardware in the loop (HIL) systems are working properly which can significantly reduce manual operator verification and debugging. The ETE’s modular rack design allows future design iterations to adapt with signal count, signal types, and other UUT requirements for HIL systems, ground support equipment (GSE), or other automated test equipment (ATE). The diverse set of measurement and sourcing capabilities allows the ETE to be used as a general purpose debugging tool, in addition to its main function as an ATE validation tool.

If you find yourself spending significant time keeping your automated test systems operational, secure, and validated, consider consulting DMC’s Test and Measurement service area to see how a Turnkey Test System may improve your testing workflow.

Learn more about DMC’s Test & Measurement Aerospace and Defense expertise and contact us for your next project.