Summary

DMC worked with a major automotive OEM that needed to expand testing capacity for their new electric vehicle (EV) production line at their high-volume assembly plant. Their existing end-of-line tester was slow, inflexible, and deeply coupled with the overall line builder’s PLC workflow. Furthermore, the test provider had a proprietary test sequence editor that only they could support. This created a challenging dependency on a singular test provider for new features and updates to their test process. The OEM wanted to remove that dependency by using industry-standard testing tools and software platforms.

To add to the challenge, the OEM’s product development team was constantly revising their test requirements while simultaneously needing to begin building up their production test cells. We see this as a common trend among our customers: a race to get to market first, to capture market share and reduce overall product development costs. As a result, the traditional “waterfall approach” of developing a product and then creating a test solution around that prototype just takes way too long. With an agile/lean new product development approach, they are seeking to parallelize product design and software development with the design, build, and commissioning of the test systems required to validate their “still evolving” products.

DMC and our close partner, NI Emerson, were introduced to the OEM’s Test Engineering Team and recognized the customer’s challenges as an excellent opportunity to showcase DMC’s Battery Production Tester (BPT) framework, which is built on top of NI’s TestStand software platform. DMC had successfully used BPT as the foundation for numerous battery test projects over the past few years, so we knew it would provide the OEM with both the value and flexibility of NI TestStand, along with the simplicity and refined features they enjoyed in their incumbent battery test provider’s solution.

Replacing the incumbent solution turned out to be no small challenge, with many factors, including politics and familiarity with legacy approaches posed real obstacles for adoption of the DMC BPT. Ultimately, though, it was hard to argue with the results. DMC deployed our BPT platform on the first line, integrating seamlessly with the OEM’s existing hardware and controls while delivering faster cycle times, comprehensive test coverage, and complete data traceability. The BPT platform allowed for rapid test development. Within 1 week of being onsite with the OEM’s new battery pack, the battery cycler, and the other test equipment at the customer site, DMC had a complete test up and running. The OEM told us that it usually took their previous test supplier over a month before the software framework was operational enough to run a full test on their packs, so this was clear value to them: ensuring the project stayed on track and met production timelines. It is also worth mentioning that DMC’s decades of battery test expertise played a critical role in helping the OEM overcome roadblocks with their BMS (battery management system) flashing process, which allowed us to provide the customer not only the tools but the expertise to quickly stand up a battery test line.

The result of our work together was a future-proof, software-centric solution that displaced a decade-long incumbent and positioned the OEM for scalable growth. DMC is now working with this same customer to deploy the BPT solution to over a dozen other EV and Plugin Hybrid EV (PHEV) battery pack production lines. The project has not only strengthened the customer’s battery test capabilities but also resulted in numerous updates, improvements, and hardening of DMC’s BPT platform, which we’re excited to share with other customers looking to optimize their battery test operations.

Figure 1: DMC’s Battery Production Test (BPT) Software. Shown Screen: BPT’s low-code BPT Socket Test Overview Screen

Customer Benefits

- 13% Faster Test Cycle Time – Increased throughput, without adding additional test stations. This optimization occurred over the span of 1 month, compared to the optimizations that the incumbent had been implementing for years.

- Multi-DUT testing – With parallelization capabilities and BPT’s enhanced multi-up configuration UIs, it’s easy to design your test sequence for one DUT but test on multiple sockets for improved utilization of capital-intensive equipment like high-power battery cyclers.

- Seamless Integration – The BPT solution fits into existing production line architectures with minimal hardware changes. The BPT HAL (hardware abstraction layer) allows for supporting different brands and models of PLCs, cyclers, and other devices and instruments required for a test. No new capital expenses are required to swap out the existing test system hardware!

- Centralized Configuration & Deployment – Push software, configuration, parameter, and grading updates across stations and easily reuse test sequences on new battery pack models.

- Expert Support – DMC’s engineers helped resolve BMS flashing issues and debug the customer’s product software to meet their production deadlines

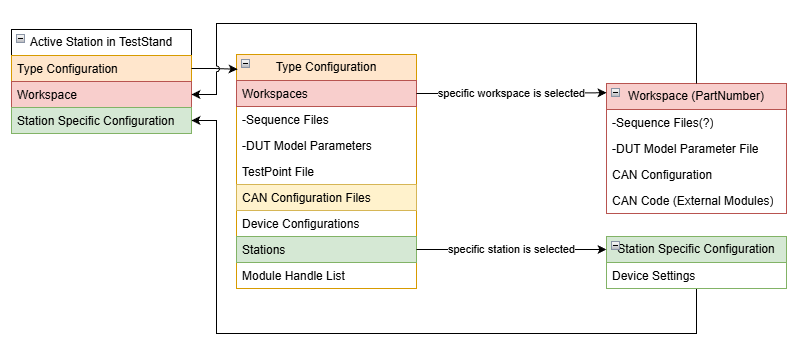

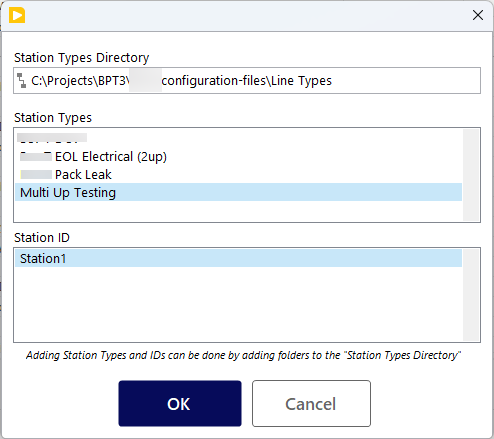

- Comprehensive Test Coverage in a Modular Form Factor – Electrical, BMS, and power capability tests in one station, or split across numerous lines for improved takt time. DMC’s BPT software is modular and supports one “do-it-all” test station or deployment across numerous, tightly scoped test stations to increase throughput. Simply select your station type and BPT manages all the configured devices/instruments and available test files for you!

Figure 2: Station Type configuration file organization

Figure 3: Test Station configuration User Interface

Technologies

Hardware:

- NI cDAQ chassis

- Industrial PC

- NI RMX power supply

- Battery cycler (any brand/model)

- PLC (Rockwell / Siemens)

- Safety interlocks, RFID scanners, thermocouples, etc.

Software:

- DMC Battery Production Test (BPT) platform

- CORTEX framework (DMC’s NI TestStand-based test executive)

- CAN, Modbus, Ethernet/IP, Automotive Ethernet, MES, MQTT, SystemLink integration modules and more!

- Custom, low-code overview screen

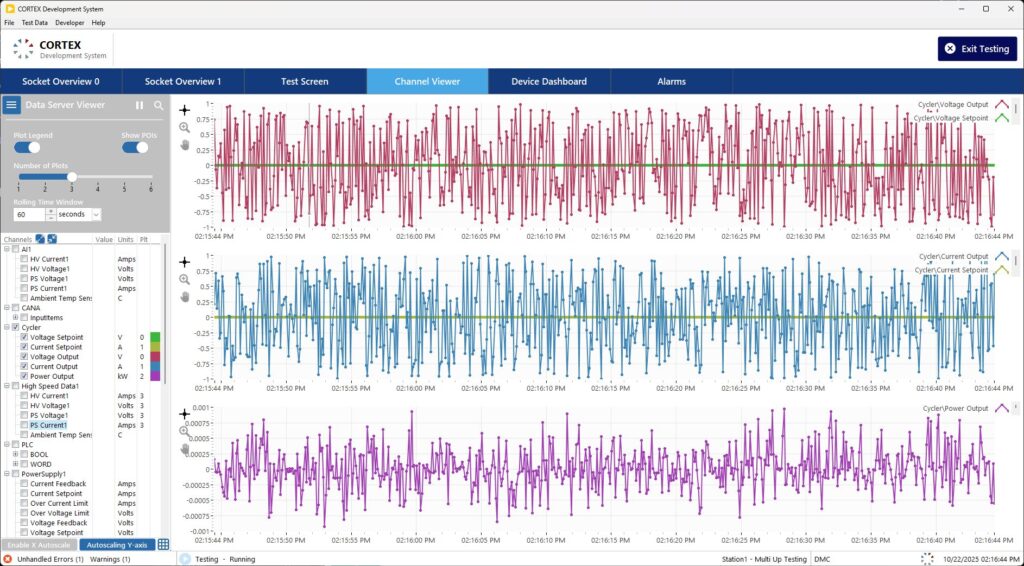

- Live waveform visualization and manual mode diagnostics

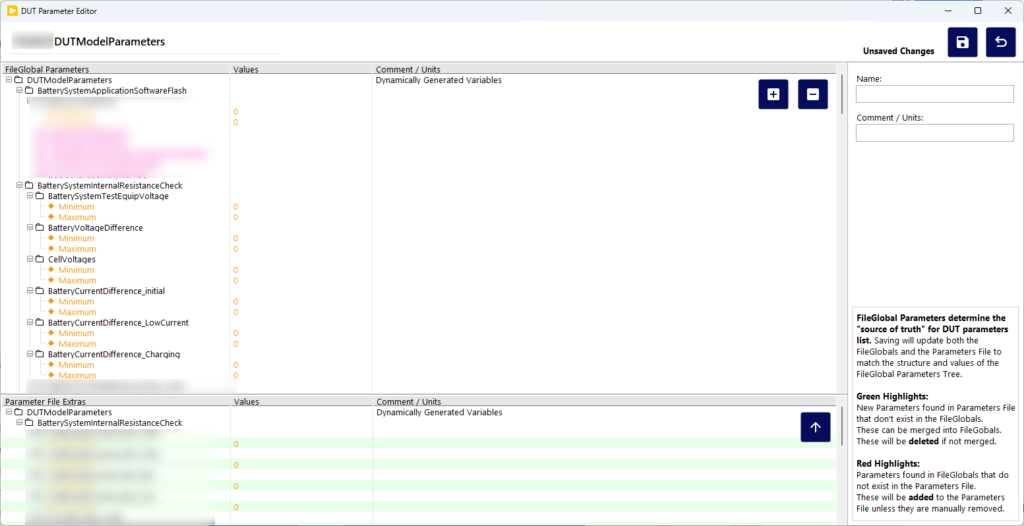

- DUT Variant Parameterization: Allows reuse of a single test sequence for multiple DUTs with different test limits or other test variations

- Separated engineering IDE and operator UI for distinct workflows

Solution

The Battery Production Tester (BPT) platform is a software package, built with NI LabVIEW and on top of NI TestStand. The software was designed with two primary users in mind:

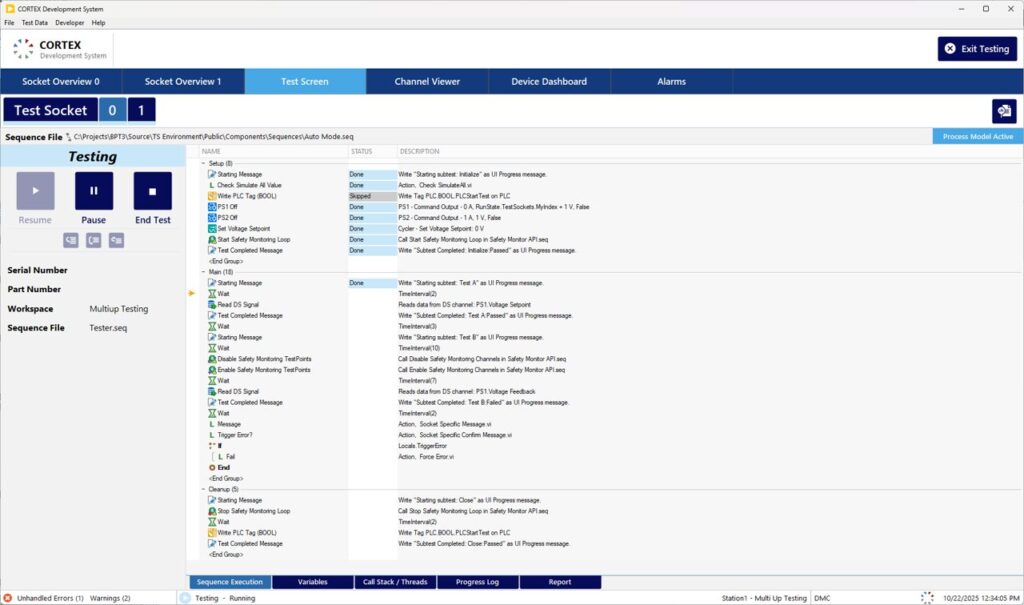

- Test Operators: People working on the production line who need a simple user experience to understand what is happening on the line and make modifications if needed

- Test Engineers: Experts on battery test who want to design optimized test sequences quickly to test new products or identify potential product defects.

To accomplish this, BPT has a “BPT Application” component that is deployed on each test station, as well as a “BPT Engineering Environment” component that is used by engineers on their development laptops. From this environment, engineers can fully configure a test station remotely, push their changes using industry-standard version control tools, and track changes made to test configurations.

The BPT Application provides rich user interfaces that show live data in summary views and waveform graphs and display parametric test results in a modern UI. Operators have access to a limited subset of functionality, depending on the user role and permissions assigned to them, either locally managed or IT-linked LDAP.

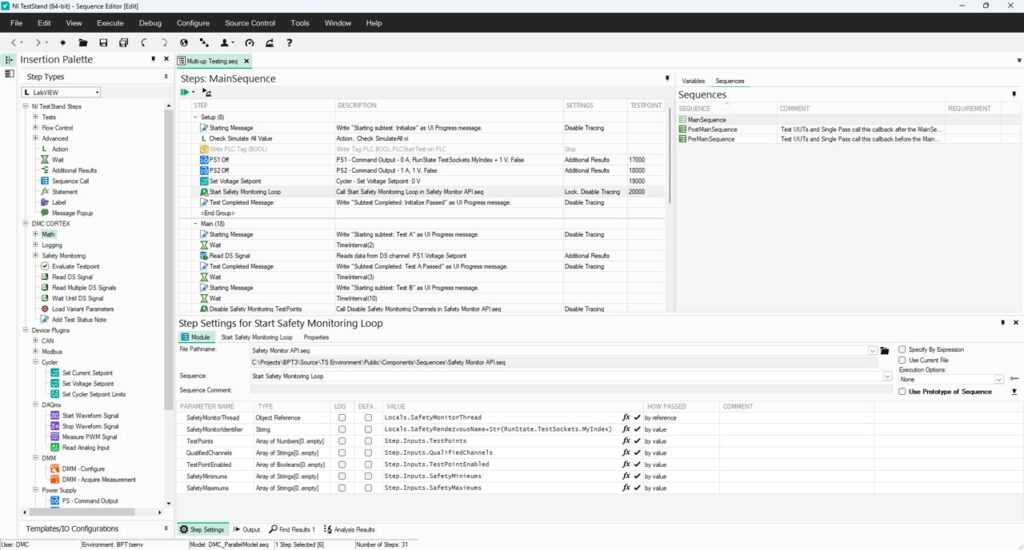

The BPT Engineering Environment provides engineers with all the power and capability that NI TestStand offers, without the complexity of setting up the TestStand infrastructure. BPT has simple configuration dialogs for all the main settings and convenient parameterization that engineers often need to test a battery pack efficiently. These smart features greatly simplify the engineering workflow compared to starting over from scratch each time. Furthermore, DMC exposes a rich and expanding library of common battery test devices and instruments (including CAN, Automotive Ethernet, Power Supplies, DI/DO/AI/DO, Modbus, EthernetIP, etc.). These sequence steps provide high-level, configuration-only building blocks that engineers can drag and drop into their test sequence. Each step can have a unique Testpoint assigned to it, which allows easy traceability into which test steps are failing most often, something your quality team cares deeply about.

Figure 4: BPT Application – Test Sequence Execution View

Figure 5: BPT Engineering Environment (Built into NI TestStand via Extensions)

The BPT platform also supports centralized configuration management, allowing engineers to push updates to multiple test stations simultaneously. By single-sourcing sequences and parameterizing them across different DUTs, the customer dramatically reduced the engineering effort required to maintain and scale their test systems.

For this project, we customized DMC’s BPT to work seamlessly with the OEM’s existing test cell setup — including their chosen battery cycler and assembly line PLCs. Thanks to BPT’s modular plugin system, making those connections was straightforward. The hardware abstraction layer (HAL) also positions the OEM to easily swap out instruments and optimize their hardware expenses in the future – without major rewrites to their test sequences. This flexibility ensures long-term adaptability as the OEM continues to evolve its battery production strategy.

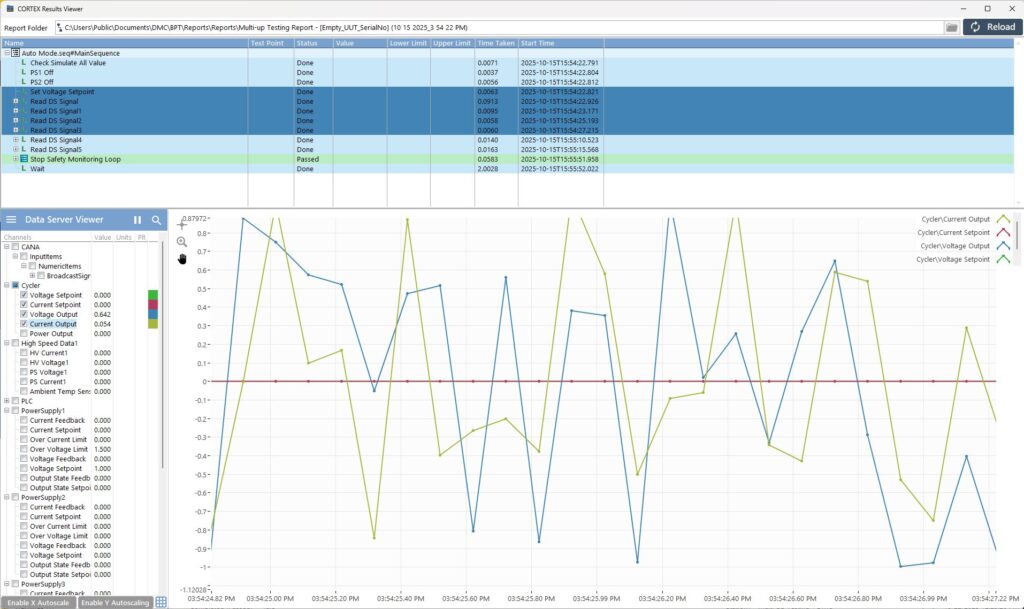

The software ran a full end-of-line test that checked electrical performance, ran BMS diagnostics, and verified hi-power charge and discharge capabilities. All the results were automatically saved and sent to a central database for easy tracking, while preserving local copies of the test results for immediate viewing on the test station if needed. The automated test software ran without any human-in-the-loop, triggered by a line PLC. The BPT UI screens gave the operators a clear understanding of what was happening with the test system and provided them with the necessary tools to step in and troubleshoot the system when needed. The engineering team could watch the test results stream in live from their SystemLink connection, making access to the test data easier than ever to retrieve and analyze.

BPT Features

Built on the CORTEX framework, DMC’s BPT platform delivers robust and scalable test architecture tailored for battery production environments. It includes many valuable features, including:

- Open, standards-based software architecture: Unlike proprietary test systems that lock users into vendor-specific tools, DMC’s BPT is built on NI TestStand — an industry-standard platform. This gives the OEM complete control over test sequences, enables easy integration with third-party hardware, and ensures long-term flexibility without vendor lock-in.

- Standardized Sequencing – Built on NI TestStand with a custom Sequence Editor and reusable step libraries, enabling engineers to develop and maintain tests efficiently using industry-standard tools.

- Hardware Abstraction Layer (HAL) – Abstracts instruments and devices through plugin classes, supporting DMMs, DAQ, serial and industrial protocols (Modbus, Ethernet/IP, Automotive Ethernet), power supplies, PLCs, and more. This allows the customer to swap out hardware as needed without rewriting test sequences.

- Configuration Over Code – Dynamic workspaces, station configurations, and device-socket mapping enable engineers to configure multi-up stations and test logic without deep programming expertise.

- Production-Grade User Experience – Includes Auto and Manual test modes, device dashboards, live channel viewer, alarms, and role-based user permissions. Operator and engineering interfaces are separated to support distinct workflows.

- Reporting & Traceability – Combines parametric test reports with engineering waveform logs (TDMS), enabling root cause analysis and complete visibility into test execution.

- Ecosystem Integration – Seamlessly connects to PLCs, MES systems, custom databases, and IT infrastructure (e.g., LDAP for user management), ensuring the test system fits into the customer’s broader manufacturing environment.

Figure 6: Live Waveform (Data Server Viewer)

Figure 7: DUT Parameters Editor for configuring variables on specific product models, enabling reuse on a shared test sequence

Figure 8: DMC BPT Results Viewer Tool that combines TestStand Report Results with Continuously Acquired Data

Let’s Start a Conversation

Looking to modernize your EV battery testing process? Have specific concerns for your battery test project? Wondering if BPT can help your team? DMC’s BPT platform delivers speed, flexibility, and deep test coverage, without disrupting your existing production line.

Contact us today to learn how we can help you scale your battery manufacturing with confidence.