In the Aerospace and Defense sectors, the push to modernize aging test infrastructure is stronger than ever. With increased funding, hyper-focus on operational readiness, and shortening timelines, organizations face a critical decision: invest in brand new test rigs, or modernize the control systems and software of their existing assets?

At DMC, we believe that control-system modernization can often be the smarter, faster, and more cost-effective path, especially for complex, mission-critical test stands. In most cases, modernization deserves some more serious consideration.

Why Modernize Instead of Replace?

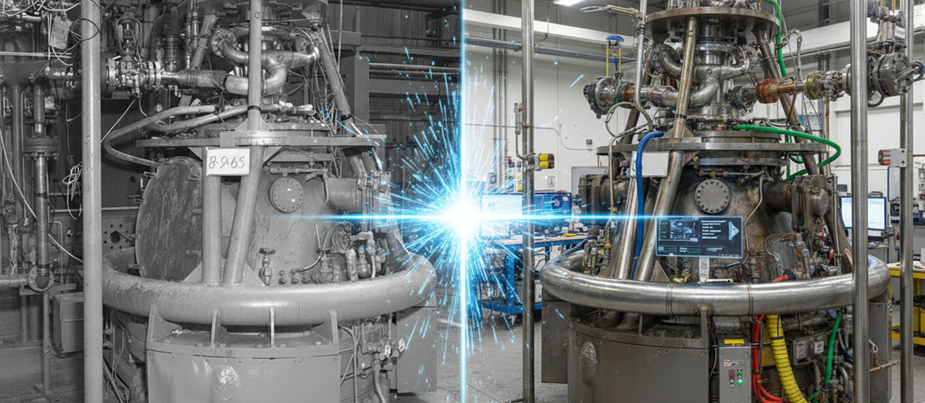

1. Preserve What Works, Upgrade What Matters

Most legacy test stands, like those used for aircraft engine components, feature robust mechanical and electrical assemblies that remain fully functional. The real bottleneck is usually outdated control consoles, operator interfaces, instrumentation, data storage, and software, which have all increased exponentially in capability and performance over the last several decades.

Meanwhile, mechanical systems haven’t changed much over the last few decades, so why replace something that isn’t broken? By focusing upgrades on the control architecture and instrumentation (software, electronics, & DAQ systems), you can:

- Significantly reduce cost, downtime, and risk compared to full system replacement.

- Meet modern requirements for cybersecurity, diagnostics, traceability, and user experience.

- Avoid the complexity and uncertainty of integrating entirely new hardware into your workflow.

2. Own Your Platform And Your Future

Modernizing with open, industry-standard platforms (like NI LabVIEW, Python, TestStand, VeriStand, PXI, cRIO, and cDAQ) means you own the software, hardware design, and architecture. This empowers your team to:

- Expand and adapt the system as needs evolve.

- Choose your support partners, whether DMC, your internal team, or another qualified supplier.

- Avoid vendor lock-in and ensure long-term serviceability.

3. Get Proven Results

DMC’s approach is grounded in a track record of successful modernization projects for commercial, military, & aerospace clients:

- US Air Force Landing Gear Test Facility (LGTF): DMC replaced an aging control system on a one-of-a-kind aircraft tire dynamometer, delivering a modern, open-platform solution that extended the facility’s capabilities and lifespan.

- Outboard Marine Engine Test Cells: DMC automated legacy test cells for a global engine manufacturer, improving data acquisition and keeping costs in check.

- Commercial Vehicle Transmission Test Rigs: By refurbishing control systems and software while preserving mechanical infrastructure, the DMC team saved clients over $1M per rig compared to buying new.

A Phased, Low-Risk Approach

DMC recommends a structured, phased process for most test cell modernization projects. This approach ensures you only invest where it matters, with full transparency on costs and timelines.

- Assessment: Collaborate with the client, stakeholders, and end users to evaluate upgrade options and risks.

- Design: Develop detailed plans for the new instrumentation and control system.

- Deployment: Build, test, and roll out the upgrade, minimizing downtime.

- Futureproofing: Allow for optionally upgrading other necessary systems later, without overhauling the control system.

Conclusion

For Aerospace and Defense organizations, modernizing test infrastructure isn’t just a budget-friendly alternative—it’s a strategic move that maximizes asset value, accelerates readiness, and supports long-term mission success. Before you sign off on a brand-new test rig, ask: What could you achieve by simply modernizing the brains of your existing system?

Contact us today to learn more about our Test and Measurement expertise and how we can help your team achieve their goals.