Data centers are the backbone of our digital economy. As construction projects surge to meet growing demand, a critical question often goes unasked: How are you testing your power systems, and are you doing enough?

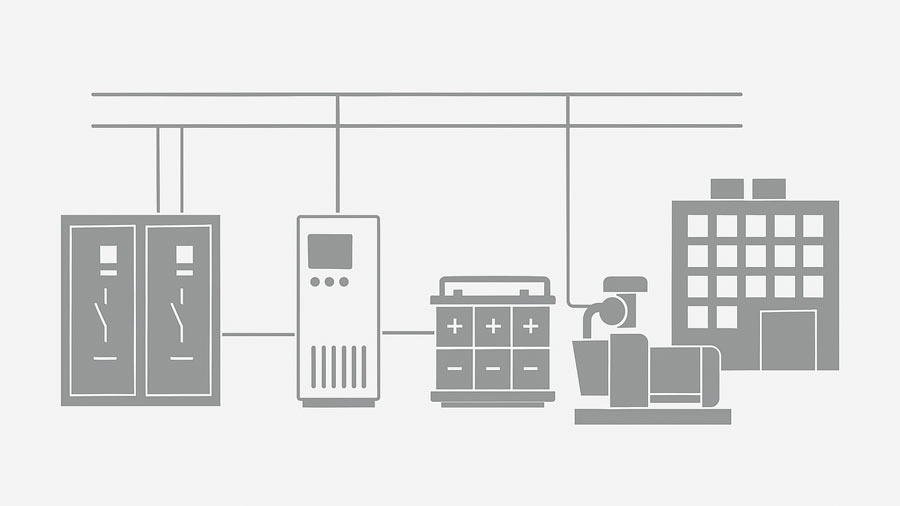

When it comes to reliability, every component in your power infrastructure matters. UPS systems, battery backups, switchgear, and backup generators all play a role in keeping operations online. But here’s the catch: testing individual components isn’t the same as testing the entire system. Each piece can pass its own validation, yet the integrated system may still fail under real-world conditions. Failure modes often emerge only when these components interact under load, during transitions, or in response to unexpected events.

Why Testing Matters

Downtime in a data center is costly and sometimes catastrophic. Power systems are complex, and their performance under stress determines whether your facility can deliver on its uptime promises. Yet many projects rely on manual checks or incomplete testing strategies that leave gaps.

Consider these questions:

- Are your UPS systems validated for transient response during failover?

- Has your switchgear been tested under realistic load conditions?

- Do your backup generators respond correctly during commissioning?

- Is your battery management system (BMS) ready for real-world charge/discharge cycles?

If you’re not confident in the answers, you’re not alone. Many teams assume that OEM testing or basic commissioning is enough. It probably isn’t.

Where Testing Should Happen

Comprehensive testing should occur at multiple stages:

- Factory Acceptance Testing (FAT) – Validate performance before equipment leaves the OEM

- On-Site Commissioning – Confirm integrated system behavior under real-world conditions

- Production Testing for OEMs – Ensure every unit meets specifications before shipment

Key subsystems to focus on:

- UPS and Battery Backup Systems – Runtime validation, transient response, and BMS functionality

- Switchgear and Power Distribution – Failover logic and power quality under dynamic loads

- Backup Generators – Load simulation and response monitoring during commissioning

- Energy Storage Systems – Charge/discharge cycles and safety interlocks

The Better Way

DMC brings decades of experience testing DC power systems for the automotive and aerospace industries, where reliability is non-negotiable. We apply that expertise to data center DC and AC power infrastructure with automated test solutions that:

- Execute custom or standard test scripts

- Control load banks to simulate real-world conditions

- Monitor power quality and transient response

- Log and report results for compliance and traceability

DMC excels at thinking outside the box. It’s what sets us apart. We don’t just deliver cookie-cutter solutions; we design and integrate unique systems tailored to your requirements and challenges. Whether you need a turnkey test station or a creative approach to integrate with existing equipment, we’ll find a way to make it work.

Component-Level Testing

Before you can trust the entire system, you need confidence in its building blocks. Component-level testing ensures that each UPS, battery module, switchgear panel, and generator meets its specifications under controlled conditions. This step verifies:

- Electrical performance and safety compliance

- Firmware and control logic functionality

- Proper response to simulated faults and load changes

Component testing is essential for quality assurance and regulatory compliance, but it’s only the first step. Even when every component passes, integration can introduce new failure modes. That’s why system-level testing is equally critical.

System-Level Testing

Component-level testing ensures each part works as intended. But data centers operate as complex systems, and failures often occur at the interfaces:

- UPS and generators may not synchronize during transfer

- Switchgear logic may falter under simultaneous load changes

- Battery systems may behave unpredictably during extended outages

System-level testing replicates these scenarios before they happen in production, saving time, money, and reputation.

Further Reading

- Automated Testing of a Mobile Energy Storage System

- Smart Energy AMP Solution

- Battery Testing with Large Scale Distributed Platform

- DMC Joins Strategic Partnership with Battery Innovation Center

Let’s Start the Conversation

Data center reliability starts with rigorous testing. If you’re asking:

- Who’s doing this testing?

- How are we testing?

- Is there a better way?

The answer is yes; there is a better way. Let’s talk about how DMC can help you validate every critical subsystem and the entire power system before it goes live.

Contact us today and let’s discuss your data center power component and system-level testing challenges.