The client reached out to DMC with a request for a new control system to manage their cogenerator data gathering and maintenance requirements. This was done in effort to comply with state utility and backup system requirements, as well as to facilitate more remote troubleshooting and maintenance of systems spanning New England. DMC was a natural fit for the project due to our broad integration expertise and experience in every SCADA system.

Monitoring Distributed Systems

Having previously switched monitoring services for their cogenerators several times, the client had around 250 cogenerators in the field running on different platforms. This meant that monitoring crews had to collect data from disparate apps by navigating through a tangle of user interfaces and systems for various portions of their business operations.

WinCC OA was selected as the new control system to introduce a more coherent system for tracking and maintenance. This also provided the possibility to unite both future and existing systems under a single umbrella. Given the scale of the operations, WinCC OA’s native support of distributed systems was well-suited to handle data over a large geographic range in a heavily-customized fashion. DMC’s goals included facilitating flexible setup and management of hundreds of sites in bespoke configurations across state lines.

Initially, DMC created an example interface and configuration for a single type of cogenerator generator. To do this, we developed a system to configure a new PLC and generator through a simplified menu that dynamically adds a new cogenerator to a site and populates its data. This reduced the process of setting up monitoring for a new generator to just a dozen mouse clicks and allowed the customer to easily deploy the system to arbitrarily large counts onsite and arbitrarily large site counts.

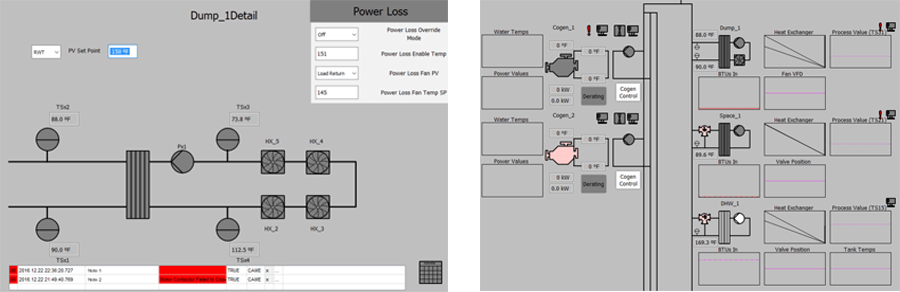

Monitoring Load Modules

Building on these successes, DMC extended the cogenerator monitoring framework to the other core component of the client's cogeneration systems - the load modules. DMC worked with the client to generate a standardized set of definitions for hot water loads such as domestic hot water, space heating, and others, built on a repeatable set of pumps, valves, heat exchangers, and other components These new modules and the existing cogenerator modules were then aggregated onto a configurable site diagram with itemized representations, pass-through of legacy overviews, and a user-customized overview. The fully WinCC OA-based system allows customizable configuration of the cogenerators and the loads with a clear path forward for new device and module types. Benefits of this system include rapid deployment, rapid load type definition and development, automated data display for the entire site, and fully-integrated generator and load control.

Employee Training

As part of this effort, the client’s employees trained with DMC to gain skills to manage their own development within this framework. This enabled the client to increase responsiveness to new initiatives or requirements and extend the existing architecture to any incremental device or design changes. They were also better equipped to support and design for further integrations, including upcoming work on new cogenerator types and site configurations. They were able to gain confidence in their knowledge and DMC’s support when it comes to approaching customization and maintenance of the system.

Future Developments

Due to the level of success with this project, DMC continues to support high-level developments on this system. Current upgrades include more configurable options on cogenerator interfaces, improvements to set-up templates, and the integration of new varieties of loads, site configurations, and custom PLC drivers with WinCC OA. We’ll be integrating some of the styling from the WinCC OA Open Library developed by DMC.

Learn more about DMC's partnership with Siemens.