DMC’s solution is built on the National Instruments platform, leveraging LabVIEW to control the electromechanical system and COTS hardware from NI and other vendors to establish the required data acquisition and instrumentation.

DMC’s solution is built on the National Instruments platform, leveraging LabVIEW to control the electromechanical system and COTS hardware from NI and other vendors to establish the required data acquisition and instrumentation.

We delivered a fully open solution (including all source code and hardware schematics), enabling the client’s in-house engineers and developers to maintain, refine, and expand the system over time to support evolving test requirements.

Design and Architecture

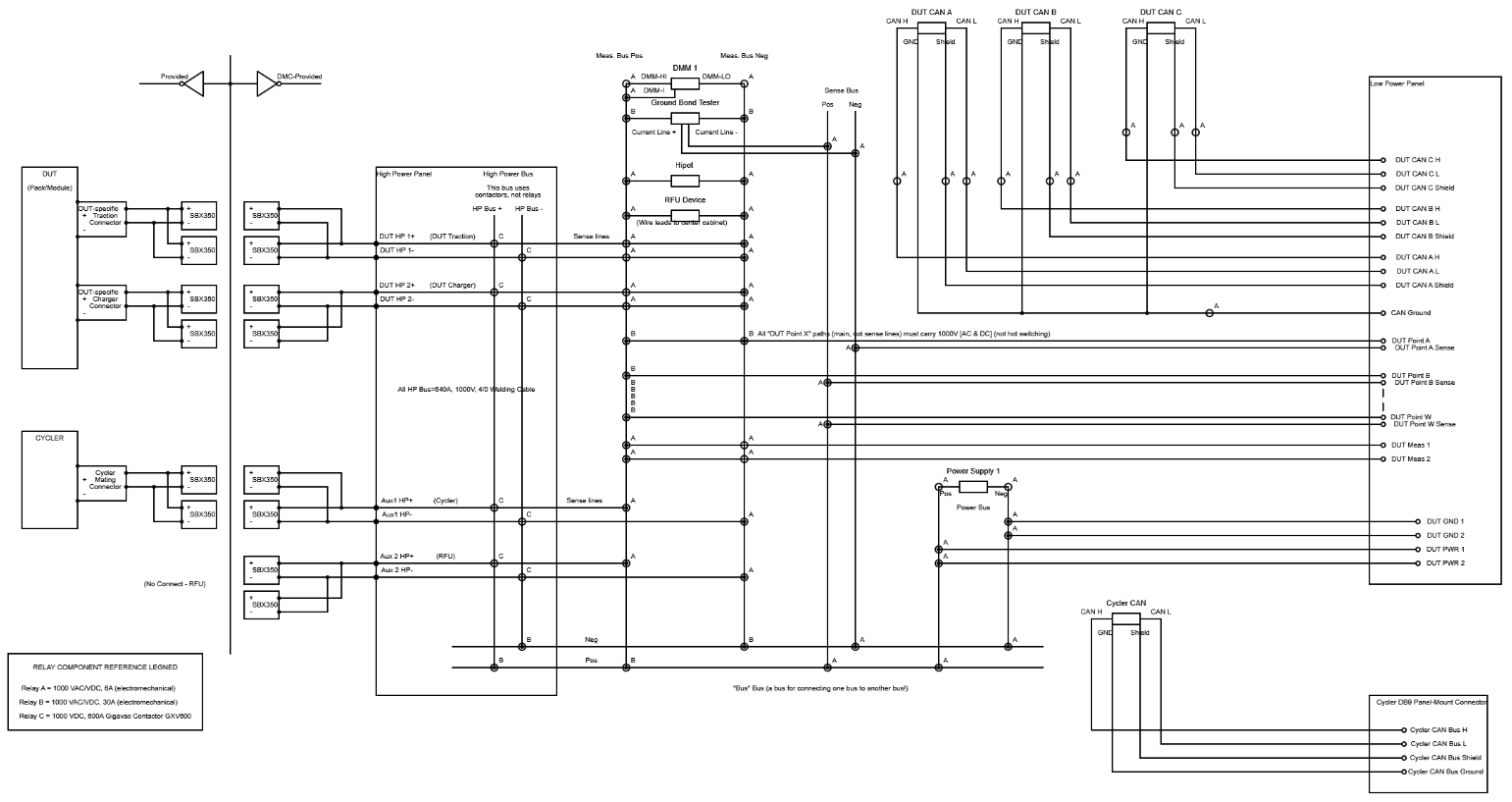

DMC worked with the customer to translate testing requirements into an abstract system state diagram depicting the connection schema that forms the backbone of the test stand.

Abstract System State Diagram - click for full-size image.

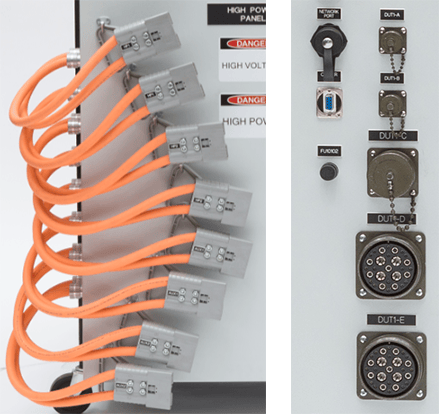

Electrical Panel Layout

%20and%20Low%20Power%20Panel%20(Right).png)

Test Stand High Power Panel (Left) and Low Power Panel (Right)

- High-Power Panel

- High-Power relays

- Length-matched high-power cabling

- Low-Power Panel

- Fusing Infrastructure

- CAN Communication

- Data Acquisition Hardware (National Instruments cDAQ Chassis)

- Housed ‘Bus’ Architecture

- Safety Interlocks

- Door Proximity Sensors

- 2 E-STOP Buttons

- External Interlock Inputs

- Hardware and Software Inputs to Interlock Loop

Bus Architecture

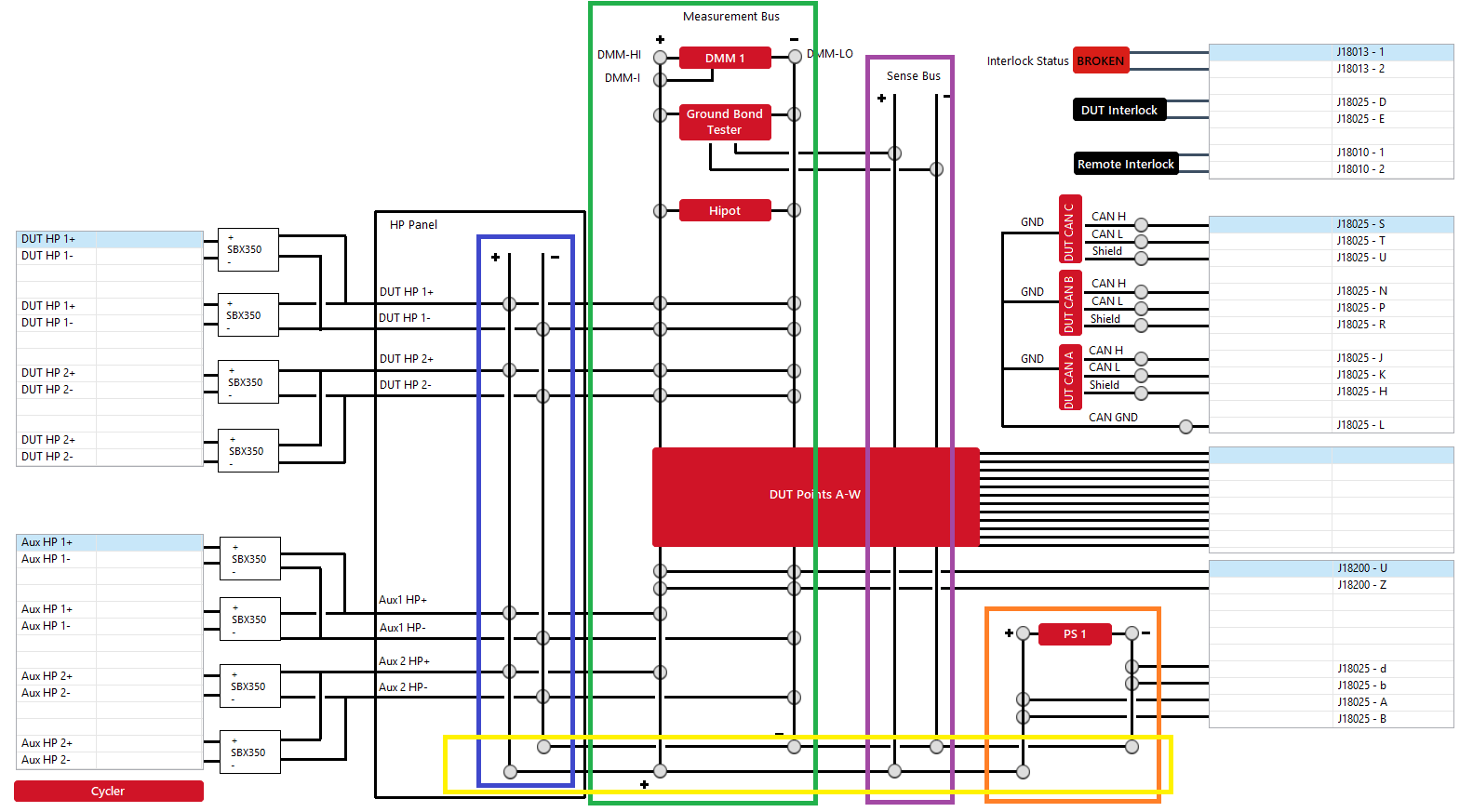

System State Diagram with Bus Highlights - click for full-size image.

To maximize the number of external (DUT) connections a single piece of instrumentation could utilize, we used a bus architecture in the electrical design. The names and a brief description of the bus function are as follows:

- Measurement Bus (Green)

- Route the testing instrumentation probe lines out to external connectors

- High Power Bus (Blue)

- Route high-power signals between the high-power connectors mounted to the test stand

- Sense Bus (Purple)

- Route the sense lines for the high current test instrumentation out to a DUT connector interface

- Power Supply Bus (Orange)

- Route the power from a programmable power supply out to an external connection interface

- Bus Bus (Yellow)

- Route signals from one bus to another bus

Software Architecture

DMC’s employed our Flex Framework, the DMCquencer, and additional LabVIEW Object-Oriented Programming (LVOOP) on this test stand. DMC’s Flex Framework is a collection of common tools and standard resources that engineers can draw from while designing an application.

Designed in LabVIEW, the application is easily extensible and open source. DMC provided the source code for the project to the customer, enabling them to further customize the test stand and truly ‘own’ the equipment.

- Testing Modes

- Automated Mode

- Single-click operator interface

- Allows for the running of pre-defined testing sequences

- Ideal for a production environment

- Manual Mode

- Unlocks full diagnostic capabilities of the test stand via on-demand user operations

- Enables engineers to construct/debug new test sequences

- Ideal for debugging or a research and development environment

Integration with DUT

An ability to interact with multiple DUTs was a crucial requirement from the customer, so DMC designed the test system to work for a variety of DUTs via a standard interface. In this case, the test system interacts with two primary DUTs:

An ability to interact with multiple DUTs was a crucial requirement from the customer, so DMC designed the test system to work for a variety of DUTs via a standard interface. In this case, the test system interacts with two primary DUTs:

- Battery Modules

- a collection of battery cells

- Battery Packs

- a collection of battery modules

A set of rugged, durable connectors for both high and low power DUT interaction expose the test system's instrumentation and signal lines. These connections points are routed to the DUT via a connector harness which allows for any future devices to interact with the system for the relatively low cost of creating a new harness. Furthermore, multiple types of measurements can be brought out on each connector enabling the test system to take a variety of measurements without having to change wiring connections manually.

For each DUT type and model number, the customer can define a unique routine built upon existing test types. This style of DUT-agnostic electromechanical design adds value to the test station as it becomes a flexible testing asset, thus eliminating the need to create a unique tester for each product.

Database Integration & Logging

MES Database Integration

DMC worked in parallel with the client’s engineering teams to integrate with an existing Manufacturing Execution System (MES) database. When an operator scans a barcode on the device under test, a query is made to the MES database to obtain a model number and automatically select which set of verification tests to run on the DUT.

Rest API & TDMS Logging

DMC implemented a variety of logging destinations for this test system. Detailed logs of system operation and internal variable changes are logged to a TDMS file while the system is operating.

Additionally, DMC worked with client software architecture teams to develop a database schema which captured the results of an automated test sequence. We utilized REST API calls to push data to this database and tested the functionality from both a simulated test stand and actual test stand environment to verify successful integration.

Project Outcome

DMC delivered two test systems to the client’s new manufacturing facility, and the modern test systems have paved the way for the consistent and reliable end-of-line testing of the client’s products.