DMC started this project by collaborating with the client to develop a method to measure layer heights of stacked material quickly and accurately. Under natural lighting, it was difficult to distinguish the adhesive layer transitions from regular variation in layer color.

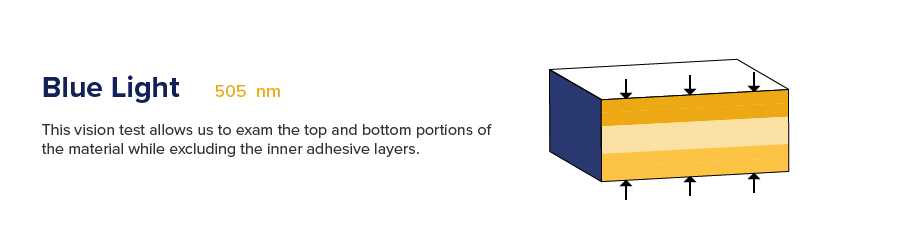

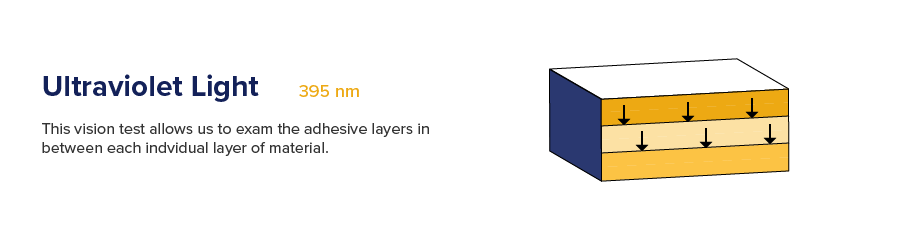

To overcome this, DMC developed a method utilizing multiple images under different lighting conditions and a bandpass filter on the camera. This method allowed DMC to accentuate the overall part dimensions in the first image to identify the top and bottom of the part. Then lighting and camera settings were modified to image the layer transitions using fluorescence for the second image.

Once the method was determined, DMC wrote a LabVIEW program to automate the process. This programming process involved turning on and off appropriate lighting and modifying camera settings before acquiring each image. The program also allows users to create and save recipes with expected layer heights for each part under test.

These recipes are used to determine regions of interest (ROIs) for the edge finding algorithms that identify the bottom, top, and layer transitions of the part. During operation, the user interface displays the lines on the acquired image as well as the measured layer heights in real-time. Measurements that are out of tolerance are flagged, and all measurements record to a file for part traceability.

A dot grid calibration and NI IMAQ tools were used to undistort images and to convert pixel measurements to real-world units. This method allows the user to quickly calibrate the system by taking images of a printed grid of dots placed in the same spot as the part under test.

Learn more about DMC’s Test and Measurement Automation Solutions and our partnership with National Instruments.