The client came to DMC with a request for an automated system to deliver powder ingredients by weight with accuracies of 0.1 lbs. The client wanted to be able to configure the software to support up to 30 hoppers so it could be replicated at several facilities. In addition, each of the 30 units could be configured to use one of two valve configurations. The client also requested that the delivery sequences of the units could be individually configured to optimize the delivery of the material given its flow characteristics.

DMC programmed a Siemens 1500 PLC using the “Optional Hardware Configuration” feature discussed in this blog. This allowed users to reconfigure the PROFINET IO network according to a predefined topology. As new ET200 racks were added to the network, the PLC would automatically assign PROFINET names, IP Addresses, and IO configuration.

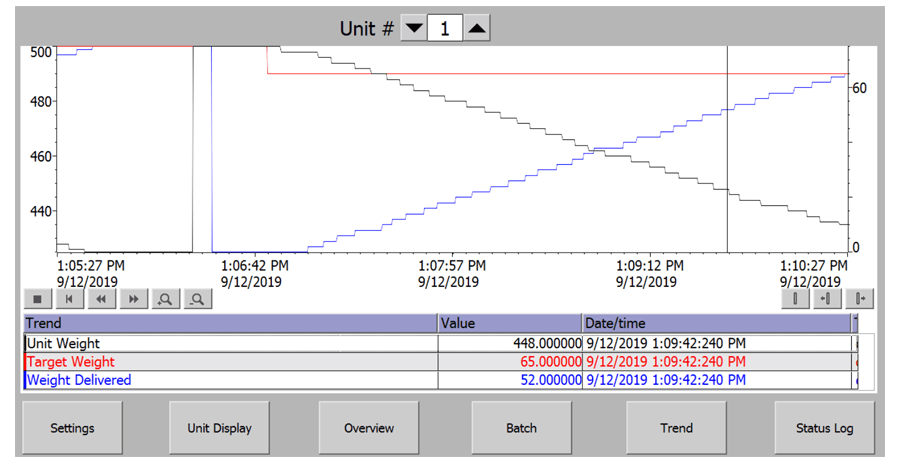

DMC also leveraged the full feature set of WinCC Advanced in order to expose all relevant process information to the operators. This included a status log that contained all batch events, a custom text log for each material, an alarm log for delivery faults, and data trending to graphically show hopper weights over the past several days. This data could be both viewed on the touch panel HMI screen and exported for further analysis.

DMC upgraded the client’s SCADA program, developed with WinCC 7, to interface with the new delivery system. Operators are now able to view unit status and delivery quantities through an industrial PC and can initiate material delivery as part of a larger batch.

Learn more about DMC's PLC Programming and HMI Programming servies.