First, a feasibility analysis was done to ensure the requirements of the system could be met and to confirm that the rest of the project would have a smooth workflow. The high-speed cycle time and resolution specification were proven possible with the Keyence hardware during the initial feasibility study. The solution was to have an LK-H022 laser triangulation head be moved in a line across the electrical contacts near the tips. A rising or falling edge datum on the mount is established during this line read. The contacts, which are in two different planes, are slightly staggered and are therefore able to be seen by the perpendicularly pointing laser. They have an expected X-position and length that is calibrated with a calibration block before testing begins.

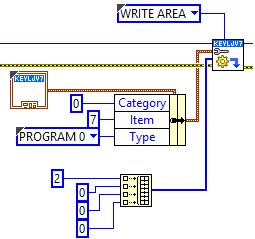

Once the system acquires the data from the laser controller, the analog signal is read for every divided double-phase encoder trigger. This single-phase encoder triggering and high-speed data storage buffer is handled by a custom DMC program in the cRIO’s FPGA. The FPGA sends buffered data to the custom PC-based LabVIEW application over Ethernet as the linear profile is being taken. Once the linear profile is fully acquired and while the machine cycles for the next part read, the PC analyzes the data with a collinearity test.

To perform the data analysis, a feature finder locates each feature depending on its location properties, X-position, and length, relative to the X datum. A Z reference plane is configurable for what plane to compare the feature depths to. Once the features are found, it is assigned a single Z depth. Then, every feature’s depths are used in a collinearity test to produce a part pass or fail depending on a variability calculation. The parameters for the variability calculation are also configurable by the client.

After ~0.4 seconds of scanning and analyzing, the pass/fail signal is sent to the PLC which communicates through the NI cRIO. The cRIO also communicates with the PLC at the start of the test to send part number and other pertinent test information.

A custom user interface for the operator is used to manually control the test procedure. This interface has graphical test results, including a chart of the image taken by the laser. The operator can also, given password permission, easily configure test and engineering parameters on this interface.

Learn more about our Test and Measurement Automation expertise and contact us for your next project.