DMC recently worked with a client that fabricates friction disks for use in automotive transmissions. It is critical that each disk meets the specified tolerances for disk thickness, flatness, and groove depth, among other properties. To confirm the disk measurements, DMC assisted our client in implementing a Keyence laser scanning inspection system to interface with their PLC-driven production system and completed EOL quality tests.

The EOL inspection system was programmed using LabVIEW software and relied on NI PCIe cards. The long-term goal of this application was to allow the client to enhance, change, and update their inspection system by using an open software platform. This will help the client quickly react to changing product and market requirements and ensure high product quality.

The application uses an object-oriented approach for configuring and executing inspections. The client desired the option to enable and disable inspections for each part, with the potential to add more inspections later. Each inspection needed to display its results in a consistent interface and log to a data file. To leverage common configuration, execution, and display code, we implemented an object-oriented class for each inspection. Each inspection inherits from an abstract inspection class that contains base methods which must be overridden for configuration and grading the raw data. This allows any set of inspection objects to be passed from the primary configuration editor to the processing state machine and dispatch the specific child class implementation of the method.

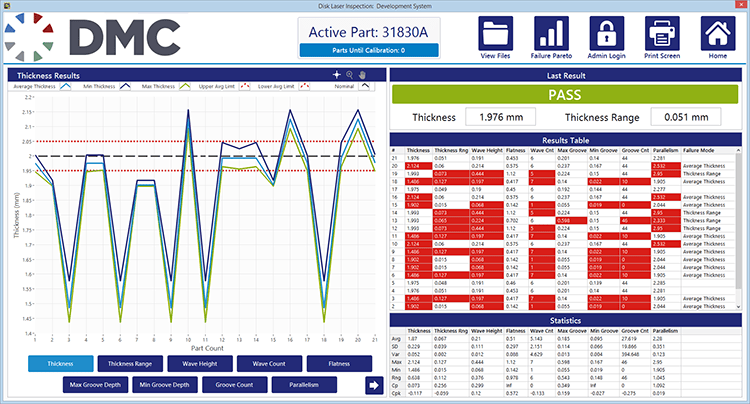

Main Inspection Screen

The application displays the relevant test information in a split screen format. Trends can be viewed over time in the graph on the left for each specific metric that the program is configured to grade. The results for each part are also shown in a tabular format and indicate any failure modes. Failures for each disk are easily identified by the large Pass and Fail indicator, which updates in real time. Statistics for the entire run can be viewed in the Statistics table at the bottom for more detailed production analysis. These results can also be summed up in a Pareto Chart for management’s analysis.

The application also allows the operator to view raw data from the Keyence sensor. The disk profiles are plotted on a real distance scale on a chart that slides off to the left of the screen.

Keyence Laser Inspection Profiles on Main Display via Slideout Graph

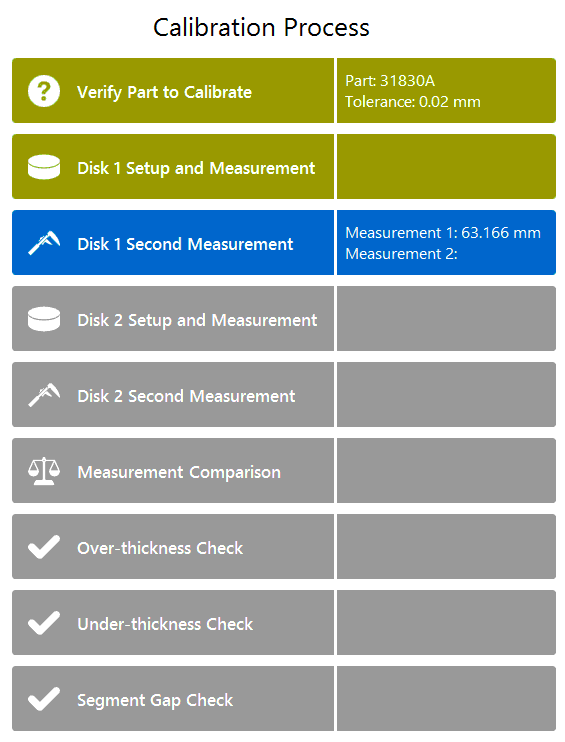

Calibration

To ensure the highest quality of measurements in this EOL tester, DMC also developed a calibration sequence that runs before any inspections begin. The calibration process not only ensures that the operators have selected the correct parts, but also accounts for the distance between the lasers automatically, so any minor adjustments will not negatively impact the quality of the inspection results. After passing calibration, the EOL tester signals for the PLC to begin production, and the inspection process executes synchronously with the PLC system.

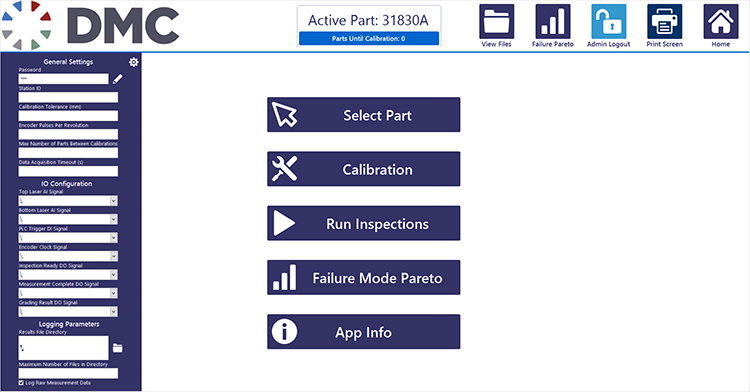

User Interface

This application utilizes some of the latest user interface upgrades that DMC has leveraged using the new DMC LabVIEW UI Suite. This package was recently developed and has improved the look and feel of our standard LabVIEW applications, helping to provide a high value to our clients. You can see the DMC UI Suite for yourself discussed in this blog post, or download here! This UI Suite is useful for almost all of our LabVIEW applications, since common features like a home button, lock/unlock security feature, and file viewer seem to show up in every custom application we build.

Home screen with clear navigation and intuitive system settings

Results

Our client is now seeing great improvements in their product quality through utilizing DMC’s robust EOL inspection system, and we are continuing to work with them to expand their quality initiatives by incorporating other features in this application.

Learn more about DMC's LabVIEW programming services.