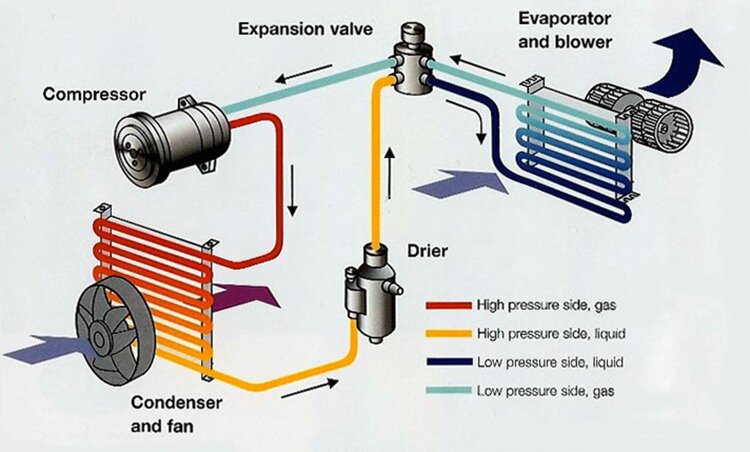

DMC's client wanted to upgrade their HVAC test chambers which were running on Allen Bradley PLC5 controllers and Wonderware HMIs. Due to the age of the system and the creation of a global LabVIEW template for other test chambers in the facility, the client requested a full system upgrade. To perform this conversion, DMC was sought out as an expert in both PLC and LabVIEW technologies.

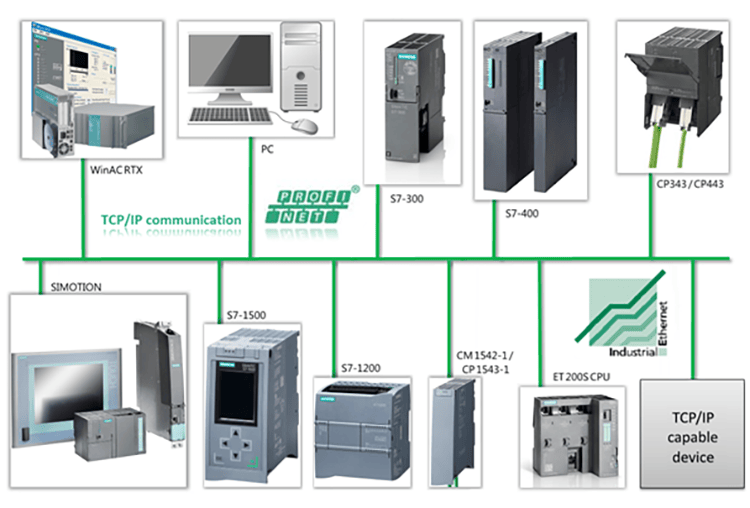

To leverage the ET200 CPU technology fully, DMC wrote the new application from scratch, incorporating the use of Siemens Open Library blocks for device control, Technology Objects for PID control, and the Siemens LCom Library for simplified TCP communication with the LabVIEW application. The PLC5 source code was used as a reference point to ensure that all functionality of the old system was captured in the new system.

In the new LabVIEW portion of the application, DMC began with the global template developed by the customer. DMC provided internally-developed tools to accomplish the TCP communication with the PLC and modified the template as necessary to fit the requirements of this system. The LabVIEW-driven HMI retained the same look-and-feel as the other test systems in the client's facility but allowed for the device control to handled by the PLC.

The delivered solution addressed client requirements and requests by pulling from DMC's internally developed tools and by implementing best practices across service areas and technologies. With this foundation, DMC was able to easily and efficiently replicate this upgrade on multiple test chambers.

Learn more about DMC's Manufacturing Automation and Intelligence services.

Learn more about DMC's Test and Measurement Automation services.