Categories

-

Extending LabVIEW with C#: Best Practices for Using DLLs for Advanced Functionality

-

DMC’s Annual Cookie Exchange

-

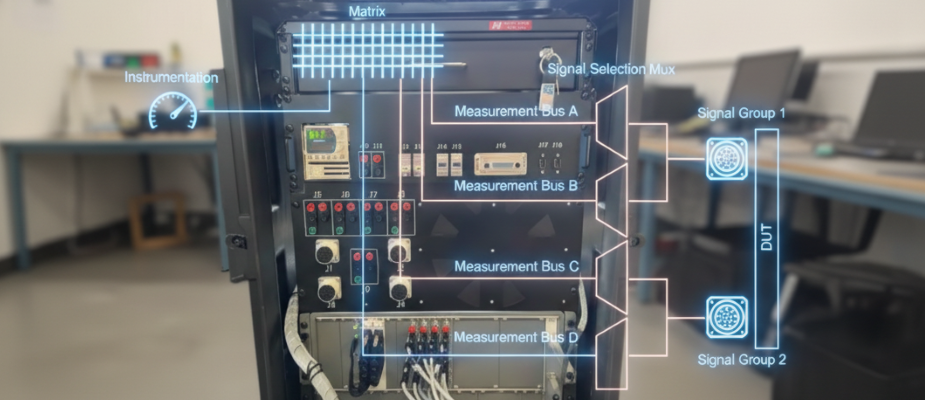

Examining Switching Architectures of Automated Test Equipment

-

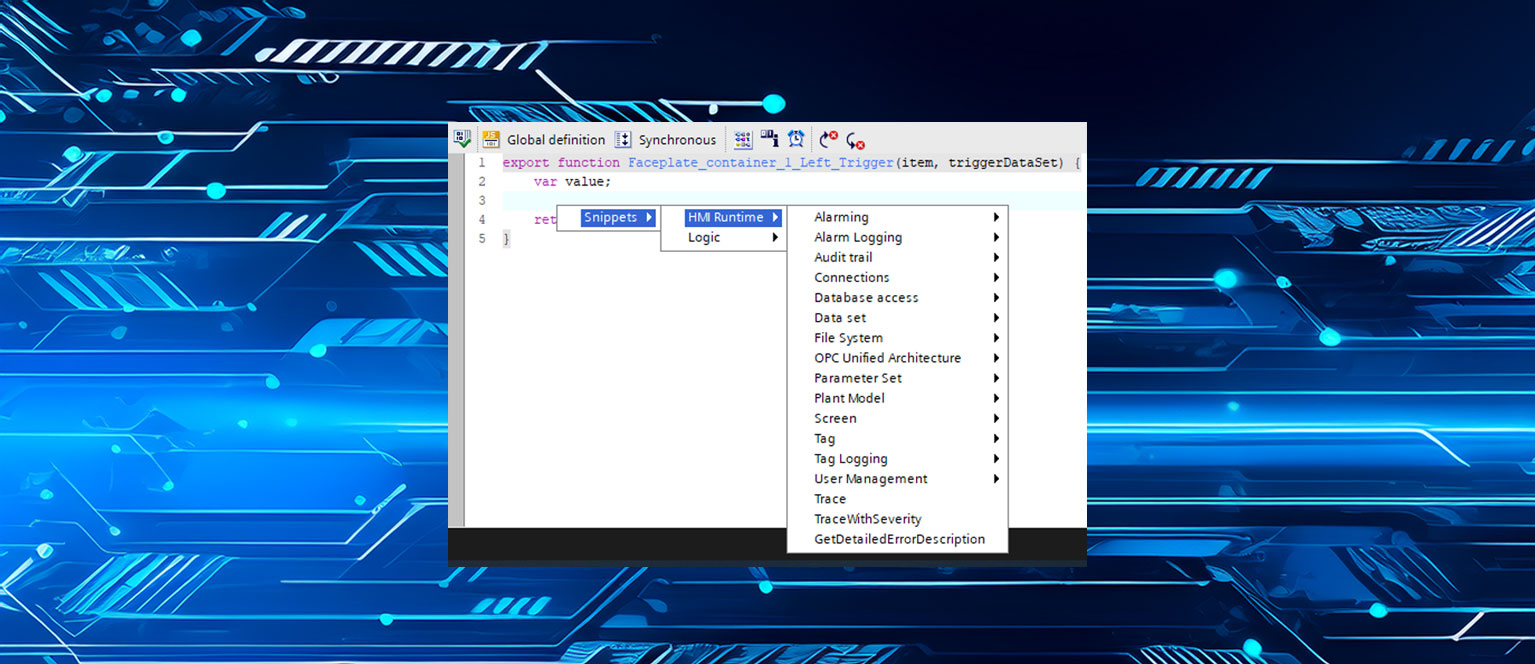

A Beginner’s Guide to Scripting in Siemens WinCC Unified for Advanced HMI Control

-

Does DMC Do Automated Test Systems for the Semiconductor Industry?

-

Custom IoT Development Services

-

DMC Quote Board – February 2026

-

MagneMotion Guide Part 11: Tuning

-

Data Center Construction: How Are You Testing Your Power Systems?