In the previous article in this series, MagneMotion Guide Part 10: Moving Track, we discussed handling moving path nodes for MagneMotion Quickstick systems. In this article, we’ll discuss the advantages of tuning your MagneMotion system and general good practices for tuning MagneMotion.

MagneMotion Guide Series

- MagneMotion Guide Part 1: Creating Configuration Files

- MagneMotion Guide Part 2: Starting up and Commissioning a Track

- MagneMotion Guide Part 3: Controlling a System with a PLC

- MagneMotion Guide Part 4: Using Path and Station AOI’s

- MagneMotion Guide Part 5: Alternative Routing Controls

- MagneMotion Guide Part 6: Track Recovery Considerations

- MagneMotion Guide Part 7: Traffic Lights

- MagneMotion Guide Part 8: Simulation

- MagneMotion Guide Part 9: Traffic Jam Prevention

- MagneMotion Guide Part 10: Moving Track

What is Tuning?

Tuning is the process of adjusting the parameters of your system that control the motion profiles used to turn motion commands (i.e., move this vehicle to this position) into mechanical movement. In the case of MagneMotion, tuning usually involves adjusting the Control Loop Parameters in the configuration file along with other advanced parameters that handle the system response to vehicles being out of position.

While some systems have automatic tuning processes, MagneMotion tuning is a very iterative process. Typically, you’ll adjust tuning parameters before running your track, make observations about the current track behavior, and then iterate on the parameters again until system performance meets application requirements.

Benefits of Tuning

There can be several different reasons why you would want to tune your system. The first is to ensure that vehicle motion is smooth. A properly tuned system will reduce vibrations and jerky movements from vehicle motion.

Tuning can also be useful in increasing the overall throughput of your system. Mistuned vehicles can take longer to get up to speed or might slightly overshoot their targets, causing delays as they need to correct their positions.

Similarly, tuning can also considerably reduce the current draw and thermal load on your MagneMotion motors. When a vehicle is moving smoothly and precisely, there is less need for the motors to draw an excessive amount of current to correct the vehicle’s positioning.

Before you begin tuning your system, it is important to consider what your priorities are in tuning. A system tuned to optimize speed and responsiveness may look different from a system tuned to reduce thermal load.

Configuration File Adjustments

See MagneMotion Guide Part 1: Creating Configuration Files for additional details.

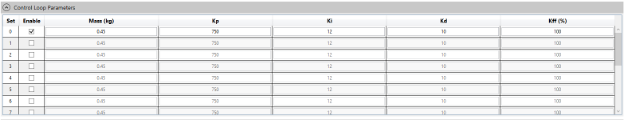

The relevant parameters for MagneMotion tuning are found in the motor defaults section of the track. While you can adjust these parameters on a per motor basis, it’s usually a good idea to adjust them on a per path basis to keep vehicle motion consistent across your track.

Here you can set up different sets of control parameters. To make use of a new set simply fill out the parameters and click the Enable check box. When commanding a vehicle to move (through NC Host or a controller) you can set the command to run at one of the PID sets configured here. Typically, it is a good idea to have a PID set for unloaded vehicles and another for vehicles that are loaded. Additional PID sets can be added, either to account for different load types or different types of moves along the track.

Below is a quick description of each parameter used in a control set:

| Parameter | Description | Increase Effect | Decrease Effect |

| Mass (kg) | This is the mass in kilograms of the vehicle. This mass should include the mass of the puck, and nest/fixture on the vehicle, and any load placed on the vehicle. | ||

| Kp | This is the proportional gain. This controls the amount of force applied to the vehicle in response to the position error. | Can cause overshooting. Increases system responsiveness. | Reduces overshoot. Reduces steady-state error. Slows system responsiveness. |

| Ki | This is the integral gain. This controls the amount of force applied based on past values of the position error. | Can cause overshooting and oscillation. Makes the system more responsive to errors over time. | Reduces overshoot and oscillation. |

| Kd | This is the derivative gain. This controls the amount of force applied based on the velocity error of the vehicle. | Reduces settling time. Decreases overshoot. Large values can cause stability issues. | Increases settling time. Increases overshoot. |

| Kff(%) | This is the feedforward scale. This controls the force used to achieve the desired acceleration based on the given mass. | Increases from 100% can cause the system to excessively accelerate the vehicle. | Decreases from 100% can cause the system to not accelerate quickly enough. |

Tuning Process

Using Virtual Scope

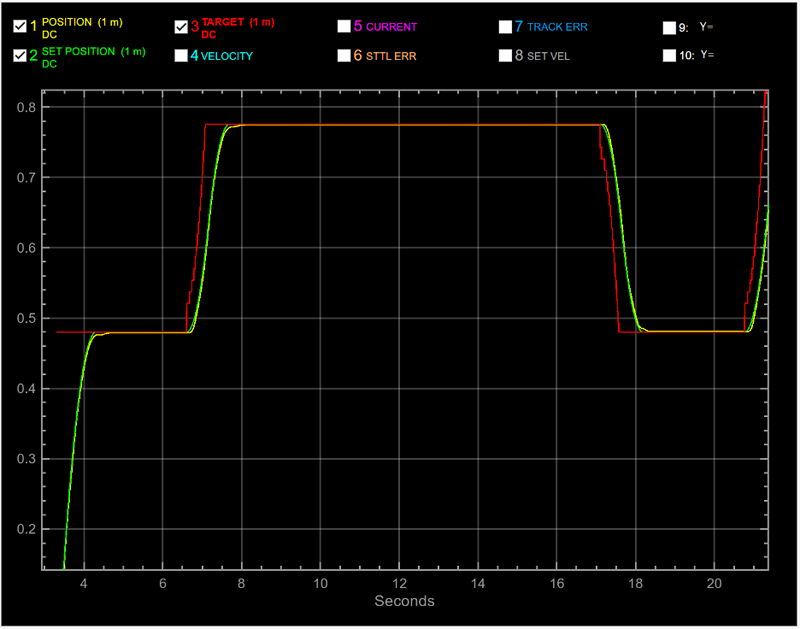

To properly tune a system, you will need to run a vehicle around your track while assessing whether the vehicle’s behavior is improved after each adjustment to the system’s control parameters

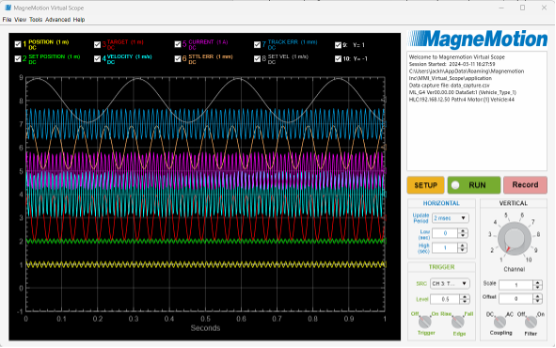

While you can certainly do this by just monitoring the system, MagneMotion has created a tool to help gather more specific motion data called Virtual Scope.

The Virtual Scope tool gathers data about a vehicle’s position error, velocity, and current use as it moves along a motor of your track.

To use Virtual Scope in your tuning process simply hit the setup button and input the IP address of your HLC controller along with the vehicle ID you are planning on tracking and the path and motor you are running your tuning tests over.

Note that for a running system it can be tricky to line up a scope of a specific vehicle crossing a specific motor. Make use of NC Host’s ability to track vehicle positions to setup a trace before the vehicle approaches the motor you are monitoring.

When a profile is captured, you can select which parameters you wish to display. You can also choose to set up a data capture to record the data from the scope into a .csv file for additional analysis.

Data Streams

The Virtual Scope tools make use of data stream files to determine which data it is capturing from the MagneMotion motor. By default, virtual scope uses a data set that includes information on the vehicle position, error, and velocity.

The virtual scope tool can gather additional information on things like motor temperature, power specifics or other details if the scope tool is loaded with different data streams by going to “Advanced” -> “Load Data Stream.” Rockwell does not publish these data stream files, but you can reach Rockwell ICT’s support team for alternative data streams if needed.

Using NC Host

While you can certainly run your tuning by setting up a PLC program to run tests, it is often easier to use NC Host to control a singular mover instead of spinning up a whole PLC program or modifying your production code.

For more details on NC Host see MagneMotion Guide Part 2: Starting up and Commissioning a Track.

NC Host also has a tool that allows you to use a temporary set of PID parameters to reduce the number of times you’ll need to change the configuration file of your system. This means you can try out PID values without needing to restart your system. (Note that any parameters changed through NC Host will be reset the next time the system restarts or the relevant path is reset).

Other Tuning Considerations

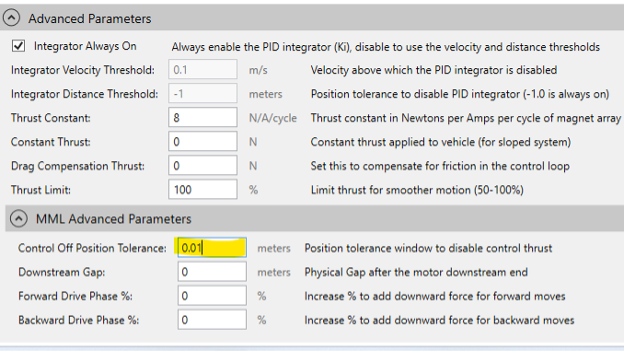

On top of the typical PID-based configuration adjustments, there are also several additional configuration modifications that can be made to improve your system’s behavior.

Disable Control Thrust

If a vehicle is having trouble settling into position, the configuration file can be adjusted to disable the control thrust on a vehicle when it is within a certain tolerance of its target. This comes at a cost to how closely the vehicle will hold to its destination but removes any oscillation or additional thrust from a vehicle that is within tolerance of its position.

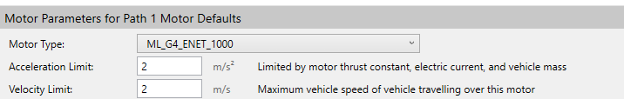

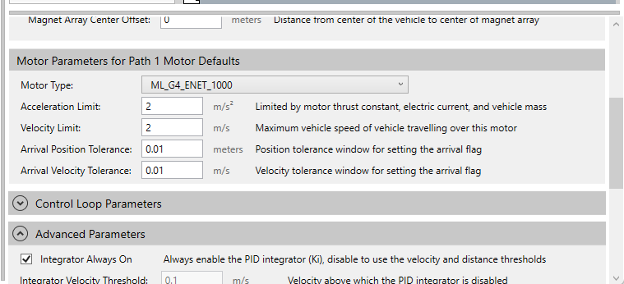

Motion Limits

If you are having trouble ensuring smooth motion on your vehicles, configuring a stricter velocity limit or acceleration limit can prevent the vehicle motion from overshooting its target too aggressively at the cost of overall system speed. Importantly, this also is the easiest way to reduce temperature issues on a motor.

Arrival Tolerance

Similarly, if a station has too large of a settling time where vehicles are adjusting themselves to get into a station position, you can adjust the arrival position and velocity targets. This way, if on that particular path vehicle tolerance is not too strict, you can reduce the delay between when a vehicle arrives at its destination and when MagneMotion indicates that the vehicle is in position.

This parameter only affects when MagneMotion considers a vehicle ‘in position’ and does not change the motion profile of a vehicle.

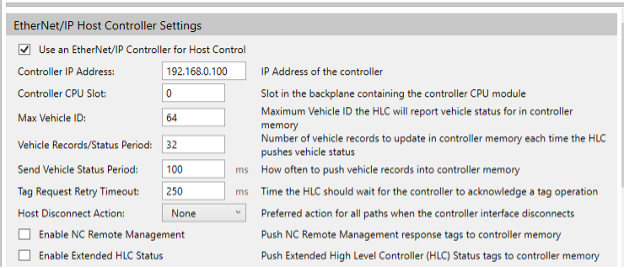

Host Controller Communication

You can also potentially reduce settling time by adjusting the system’s communication with its host controller. For high throughput systems, changing the Send Vehicle Status Period or the Vehicle Records/Status Period values can reduce the delay caused while waiting for the Node Controller to tell the host controller that the vehicle has arrived. Care should be taken when adjusting these values to ensure that you are not overloading the communication resources of the Node Controller or the Host Controller.

On a host controller, this update frequency also depends on the cycle time of the MagneMotion device handler.

Also note that these settings are specifically for systems that make use of Rockwell’s ICT library, see MagneMotion Guide Part 3: Controlling a System with a PLC.

Learn more about DMC’s MagneMotion programming expertise and contact us today to get started on your next project.