The reusability of code is fundamental to saving development time as well as reducing the number of headaches on commissioning and startup. Solid, proven libraries (like the Siemens Best Practice Control Modules (BPCMs)) are key tools to developing consistent code throughout your PCS7 project. This blog aims to introduce you to the Siemens BPCM Library and highlight some reasons you should use it.

What is the BPCM?

The Siemens BPCM takes its cue from the S-88 batch model. It aims to give developers a predeveloped and tested library of control modules, the lowest level of the S-88 model. Control modules may reference actual hardware, like valves or motors, or they may consist of a controller and an actuator such as a PID temperature controller and modulating globe valve. The BPCM contains fully developed control modules to address all of the routine equipment and controllers throughout your plant.

Valve Example

Not every valve is identical. Whereas one may be a normally closed air-over-spring valve with no feedback, an adjacent valve may be air-over-air with position feedback on either end of its stroke. The BPCM recognizes there is no one-size-fits-all valve prototype and it also eases a developer’s pain by providing variants on the control module to account for these differences.

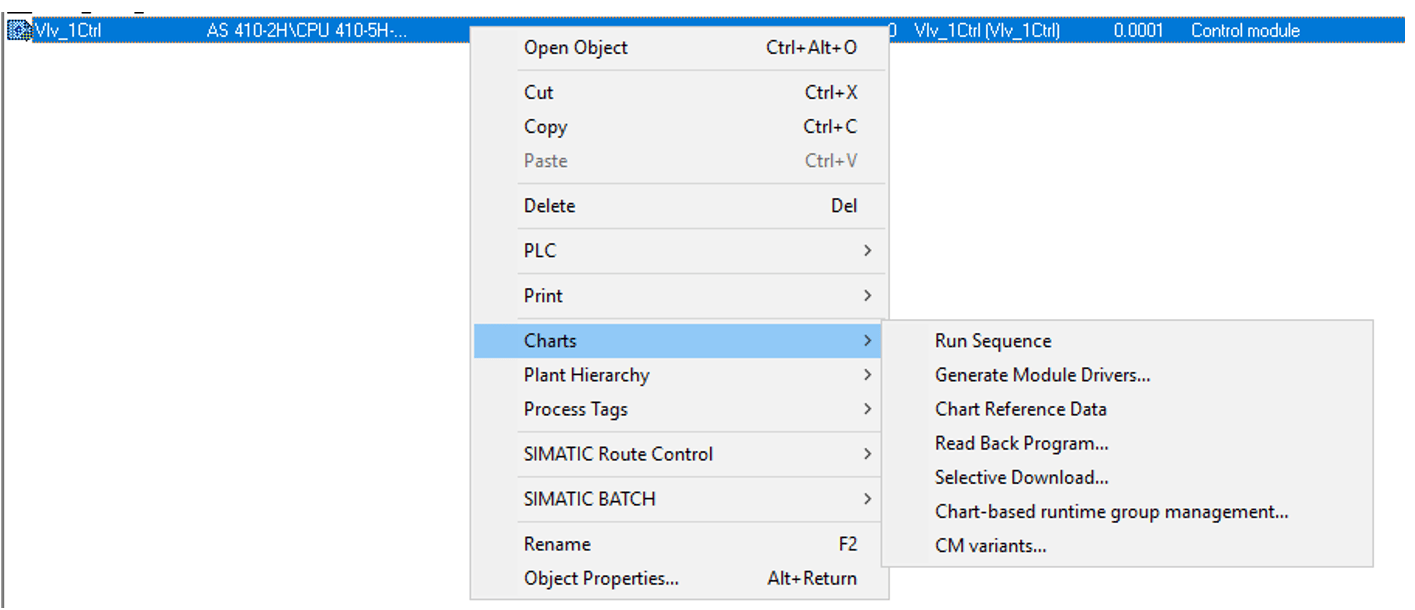

Drag a Vlv_1Ctrl object from the library into your project hierarchy to create an instance of the control module type and give the object a unique and meaningful name. In this case, the valve I’ve created corresponds to YZ-0101 on my P&ID, so I’ll run with that. By right clicking on the object, you’ll see the option to define CM Variants:

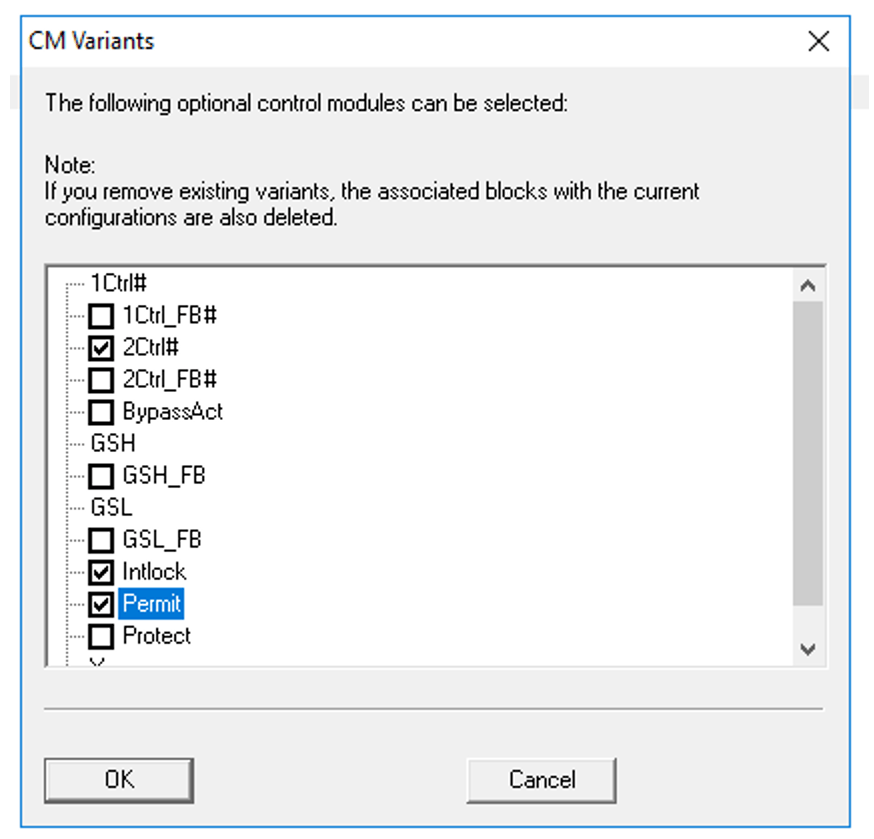

Variants are optional ways you can modify the behavior of the CM type. Below, you can see I’ve selected the 2Ctrl, Interlock, and Permit variants. These variants will create additional blocks on this instance of the Vlv_1Ctrl object – namely, it will create Pcs7DiOu blocks to control the valve in either direction (open vs. close) as well as provide Intlk08 blocks that I can use for my valve interlocks and permissives.

With just a few clicks, we’ve created all of the required blocks to configure our valve. From here, we can configure the connections for our CM with either the Technology view (great for bulk engineering) or on the CM’s chart in the Continuous Funciton Chart editor.

It’s always better to let the tools do the work for you — in this case, the Siemens BPCM Library is an essential tool to developing consistent, manageable code in Siemens PCS7. If you’re considering PCS7 for your next process automation project, reach out to us at DMC!

Learn more about DMC’s Siemens Solutions Partnership and contact us for your next project.

Read part two of this series: Bulk Engineering with Siemens BCPM in PCS7