Introduction

A majority of function generators are only capable of driving a couple of hundred milliamps, which is fine for most applications. If you want more output current, you can shell out $400 dollars for a professional signal generator amplifier, or you can do what I did and hack one together for under $40.

A signal generator is an indispensable tool for developing and testing electronic designs. You may find yourself wishing yours could output more current. You could test your power supply design by feeding in a noisy supply voltage, or you could see how it will handle a specific amount of input ripple. If you do this sort of thing regularly, you may want to invest in professional equipment. But, if you are on a budget, or only need this sort of thing occasionally, then keep reading.

Backstory

When I first started learning electronics in grade school, I had dreams of being able to build anything I wanted. After purchasing components in single quantity from Digi-Key for my first few projects, I learned a disheartening lesson.

It almost always costs more to make something yourself than to buy a finished product.

It was then I wrote Tim’s Golden Rule of Building Electronics:

“I shall not build what can be bought unless mine shall be better or cheaper.”

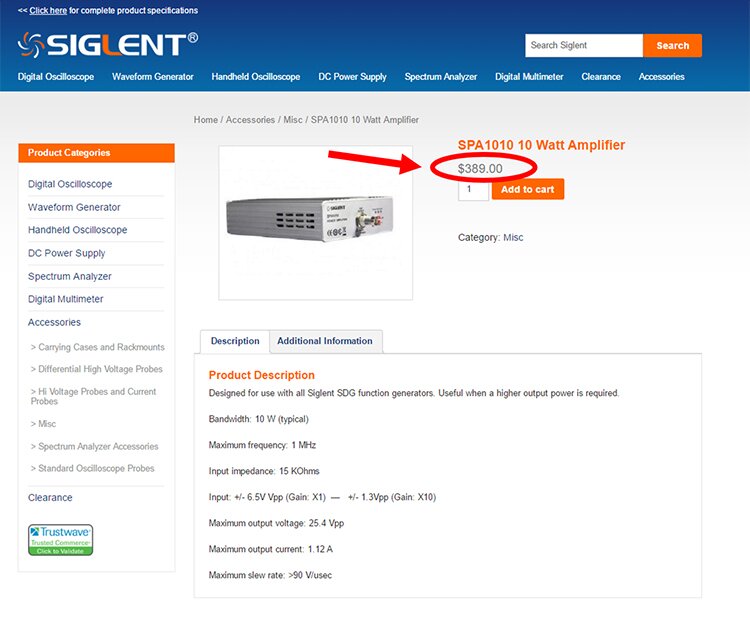

So, before embarking on this project, I checked to see if there were any low-cost units on the market. The least expensive option I could find was the Siglent SPA1010 at just under $400. This unit would work for most cases, but only has a max output current of 1.1Amps, which just wasn’t enough for me.

Figure 1 – Siglent SPA1010

Signal Generator Amplifier DIY

Unable to find a low-cost option, I resolved myself to designing my own signal generator amplifier.

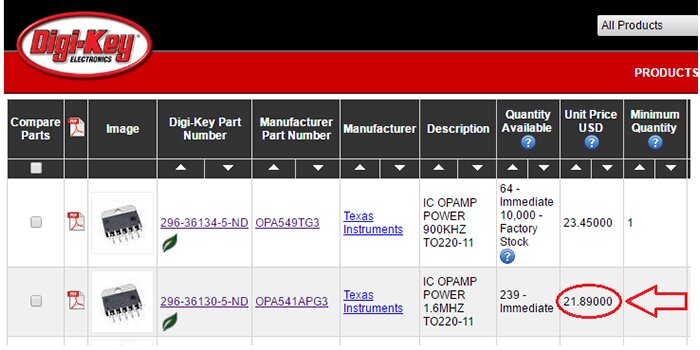

I hoped that I could design the amplifier around a high-power OP Amp. Searching for the highest output OP Amp on Digi-Key revealed the OPA541 and OPA549.

The OPA541 can handle +/- 35V rails, whereas the OP549 can only handle +/- 30V rails.

Since More Voltage = More Better, I went with OPA541.

I felt good about this selection, and I felt even better when I heard on their podcast that the guys at Macrofab were designing a power supply using this same OP Amp. Now, I just needed to whip up a schematic and layout a PCB (with a monster heatsink) to handle the OPA541.

Wait, Tim! Don’t forget about your golden rule!

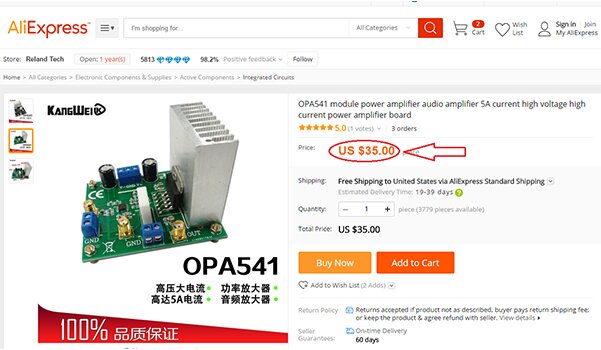

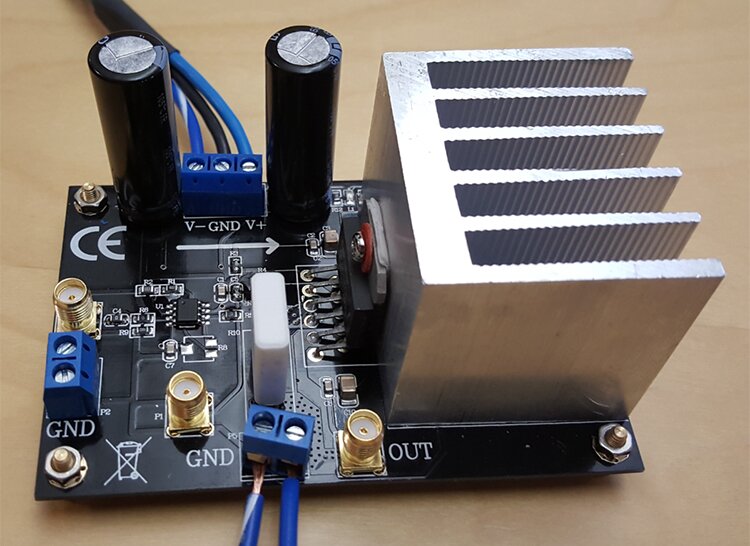

Before embarking on my design, I decided to see if there were any breakout boards available for the OPA541 (preferably with a heatsink). I couldn’t find anything from the usual suspects (Adafrut, Sparkfun, etc.), but I did find something on Aliexpress.

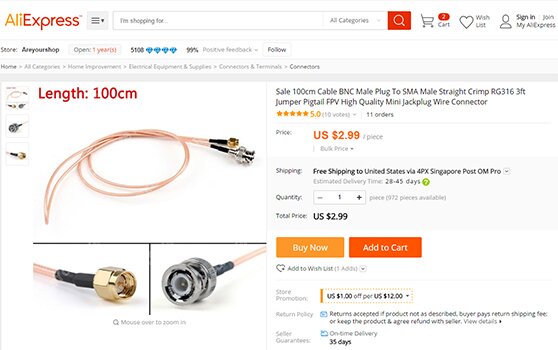

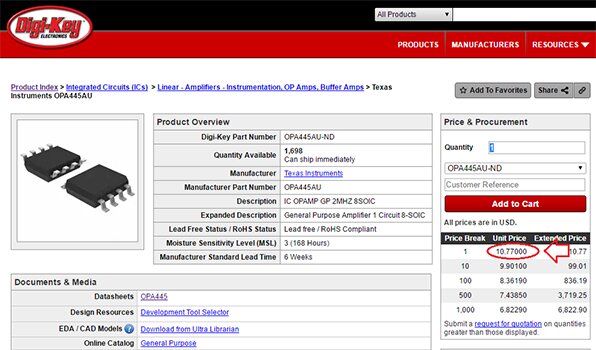

Like most things on Aliexpress, it looked too-good-to-be-true. I found an OPA541 breakout board with free shipping for $35. The OPA541 alone costs almost $22 from Digi-Key in single quantity. So, I ordered one plus a few SMA to BNC cables for $3 each.

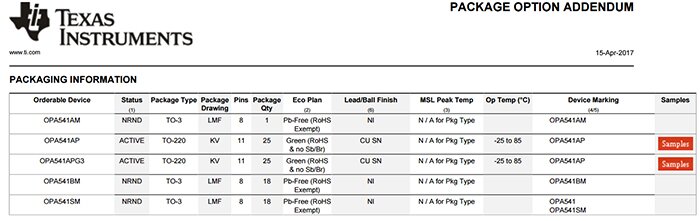

Figure 2 – The OPA541 cost almost $22 in singles

Figure 3 – Inexpensive SMA to BNC cables

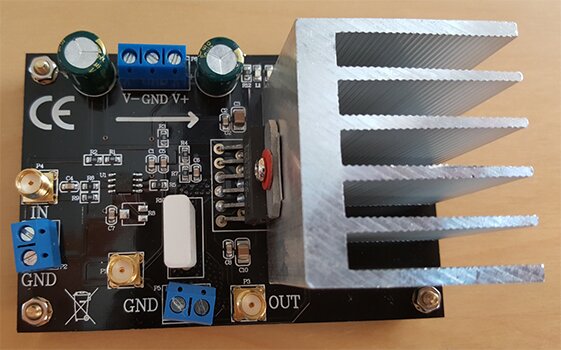

A few weeks later, the unit arrived and looked to be as advertised.

As expected, the amplifier came with zero documentation. The circuit looked simple, so I knew I could reverse engineer it if necessary. Instead, I decided to power it up and see what happened. It was immediately apparent that it used capacitive AC coupling because it only amplified AC signals while ignoring any DC offset applied.

Having nothing to lose, I sent a message to the seller on Aliexpress asking for a schematic. I got back a one-word reply “email.”

I sent him my email address, and he sent me a link and a password to a Chinese file-sharing site which yielded a PDF schematic of the device. Awesome!

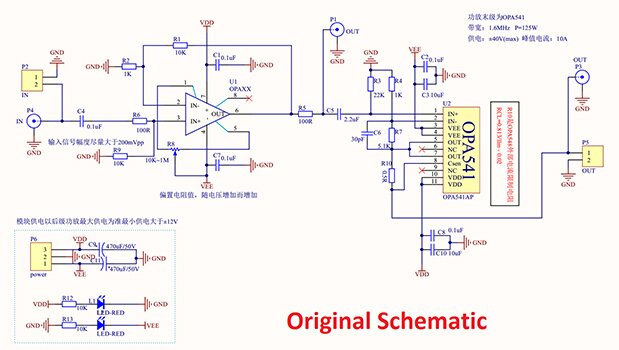

*Click to enlarge

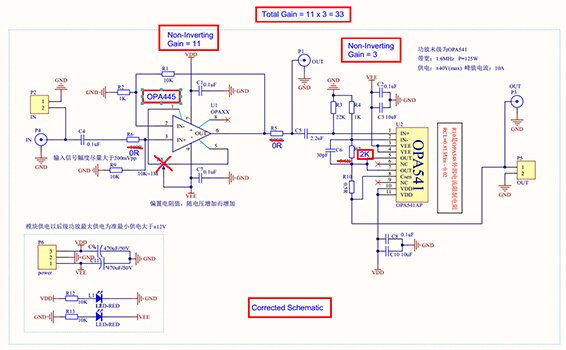

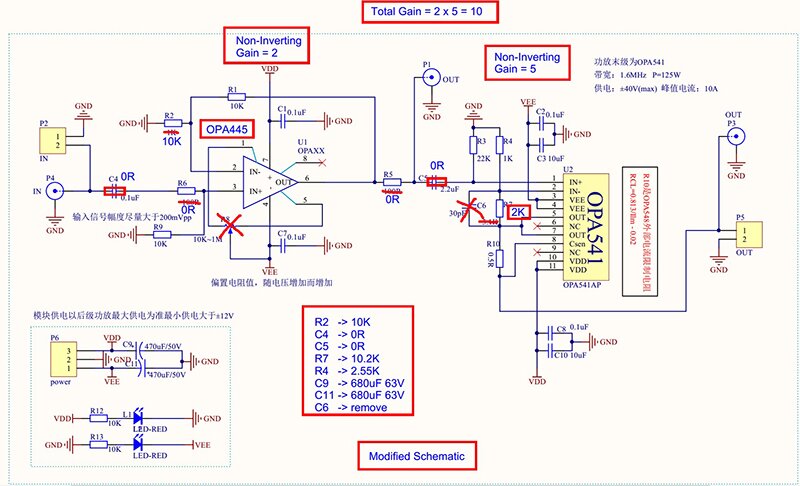

I noticed values for many components were not correct, so I marked up the schematic to show the actual values. The schematic is a little messy by my standards, but it was easy to see how it works. It is a two-stage amplifier. Both stages are set up as non-inverting with the first having a gain of 3 and the second a gain of 11 for a total gain of 33.

*Click to enlarge

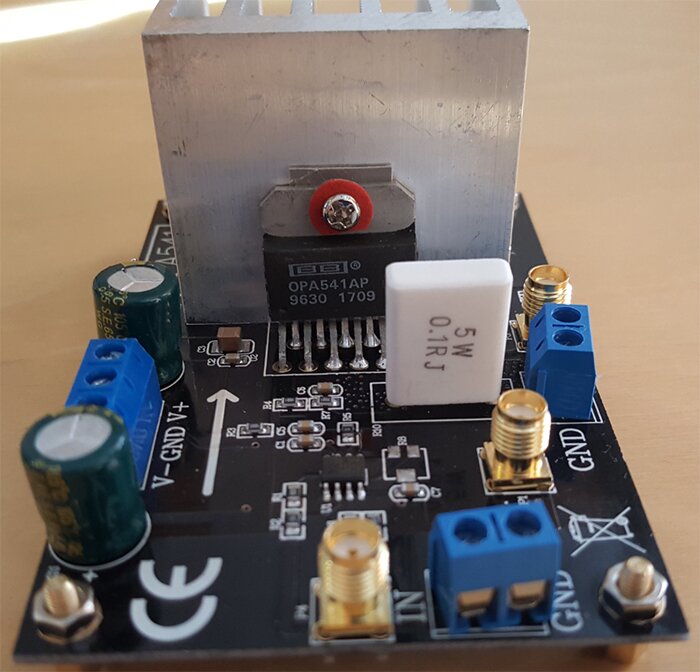

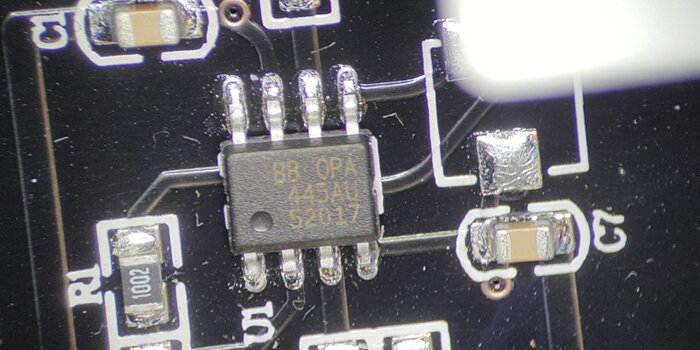

The most insane thing I discovered was that the first stage OP Amp is an OPA445, a high voltage OP Amp that costs over $10 in single quantity!

This, plus the OP541 (which costs $21), means I got $31 in chips alone for $35. Assuming these parts are legit, that’s a good deal in my book. Even if the OP Amps are counterfeit, the PCB, heatsink, and connectors are still worth $35 when considering that my alternative was to design and make my own from scratch.

Figure 4 - OP Amp for OPA541 Module

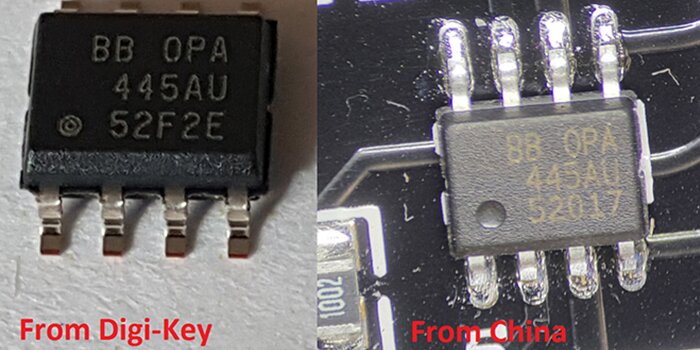

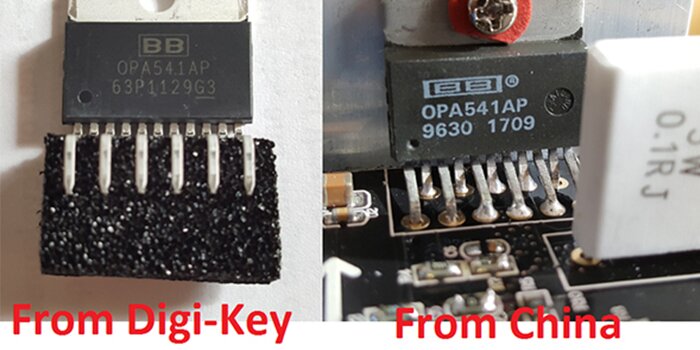

Below are side-by-side comparisons of the parts from China and ones purchased directly from Digi-Key. They don’t look identical, so I’m not sure if the parts from China are genuine.

There are two variants of the OPA541AP. One has a G3 suffix. Perhaps this explains the difference between the packages.

If anyone knows more about these ICs, please feel free to write in the comments.

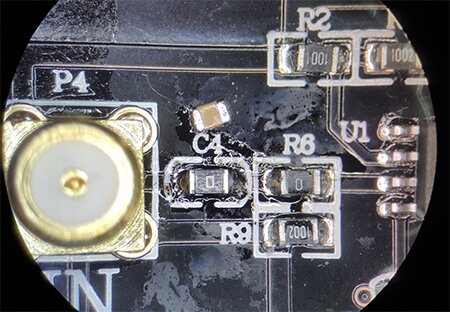

To allow the device to amplify DC, I replaced C4 and C5 with 0 Ohm resistors. See below where I removed C4 enabling me to solder a 0 Ohm resistor in its place.

Other Changes

I changed the overall gain to 10 to simplify the mental math required.

To change the gains, I did the following:

- R2 changed to 10k. Since R1 was already 10k, this set the first stage gain to 2. [1+10k/10k = 2]

- R4 changed to 2.55k, and R7 changed to 10.2k which set the second stage gain to 5. [1+10.2k/2.55k = 5]

- Upgraded the main Sanyo brand capacitors with Panasonic 63V rated caps because the original caps were only rated for 35 volts despite the schematic calling for a 50-volt rating.

Final Schematic

Below is the final schematic including all of my modifications.

*Click to enlarge

Testing

With the modifications complete, it was time to test the performance.

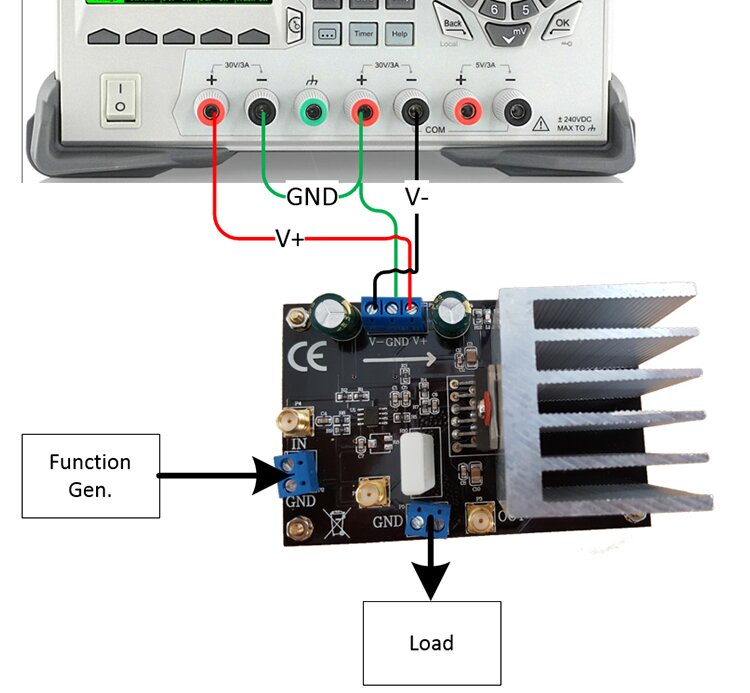

I connected the amplifier to our Rigol DP832 and configured the DP832 to provide +/-30 volts as shown in the diagram below.

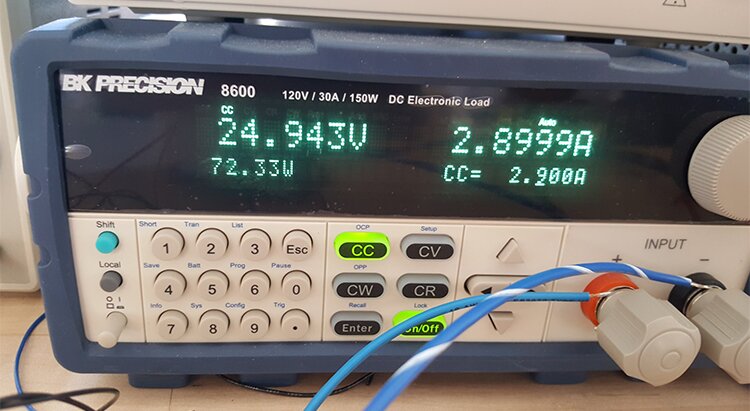

For the first test, I fed in a constant DC signal voltage of 2.5 volts. As expected, the amplifier output a constant voltage of 25 volts thanks to our 10x gain. We fed the output to our BK Precision 8600 programmable load and set it to pull 2.9 Amps, which is close to the maximum of 3 Amps for our Rigol DP832 Power Supply. We were able to source over 72 Watts to the programmable load! Sweet!

Our power supply was running close to its maximum output of 3 Amps and supplying 87.7 Watts. Since it was providing 87.7 Watts and our load is pulling 72.3 Watts, the amplifier would have been dissipating the difference between those two values, or 15.4 Watts.

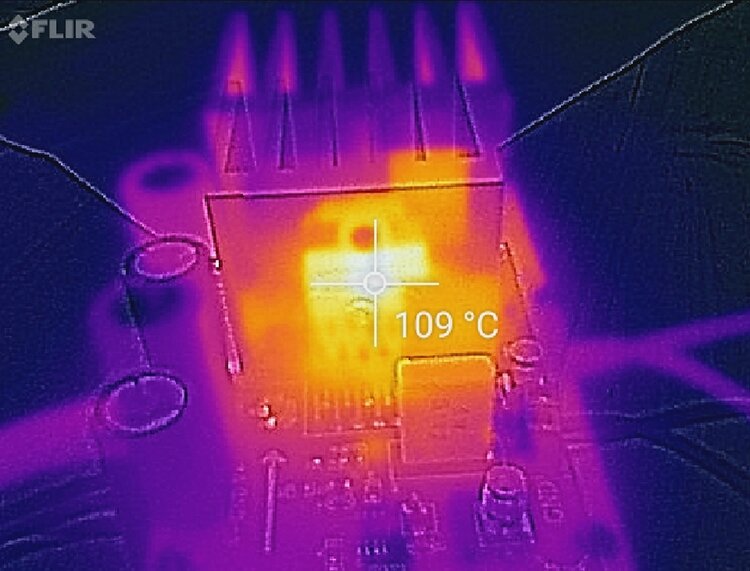

The thermal image (and the burn on my hand from touching the OPA541) confirms the amp was getting hot.

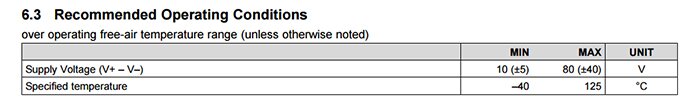

It got hot but was still operating below its 125˚C limit as shown in the datasheet snippet below:

To minimize heat dissipation, we have to remember to set our power supply voltage just a few volts above our desired max voltage output from the amplifier. Doing so will reduce the voltage differential and hence reduce the power dissipated by the amp.

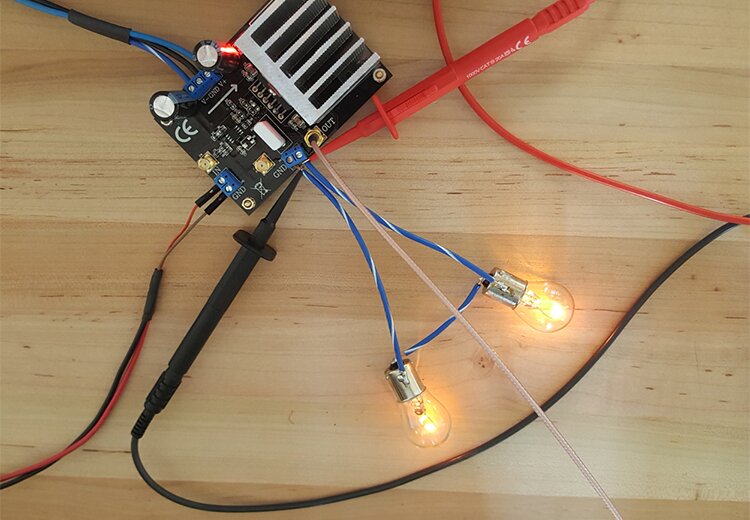

Next, I connected two 12v automotive light bulbs in series to act as a load and connect our differential Oscilloscope probe across the load.

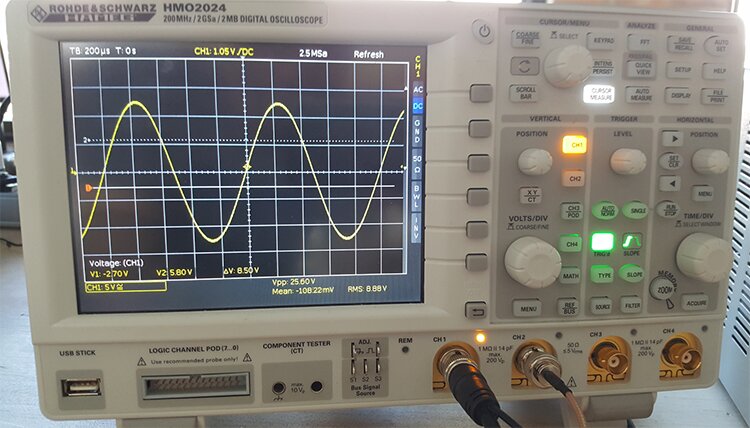

I then connected the function generator and set up a 1kHz sine wave set to 2.5 volts peak to peak.

The Oscilloscope shows a ~25-volt peak sine wave at 1kHz as expected.

Below is a video showing the same setup but at 0.5Hz instead.

Conclusion

Overall, I’m quite pleased with my $40 investment. A few weeks of waiting followed by a few minutes of soldering yielded a nice addition to the test bench. It will come in handy for testing future electronic designs.

Learn More About DMC's Embedded Development and Embedded Programming Services or Contact Us to start developing a solution that works.