Categories

-

DMC is Expanding to Tampa

-

DMC NYC Sets Sail on a Sunset Cruise

-

DMC Expands Chicago Fabrication Studio and Capabilities

-

Top Takeaways from ICC 2025: What DMC Learned and What It Means for You

-

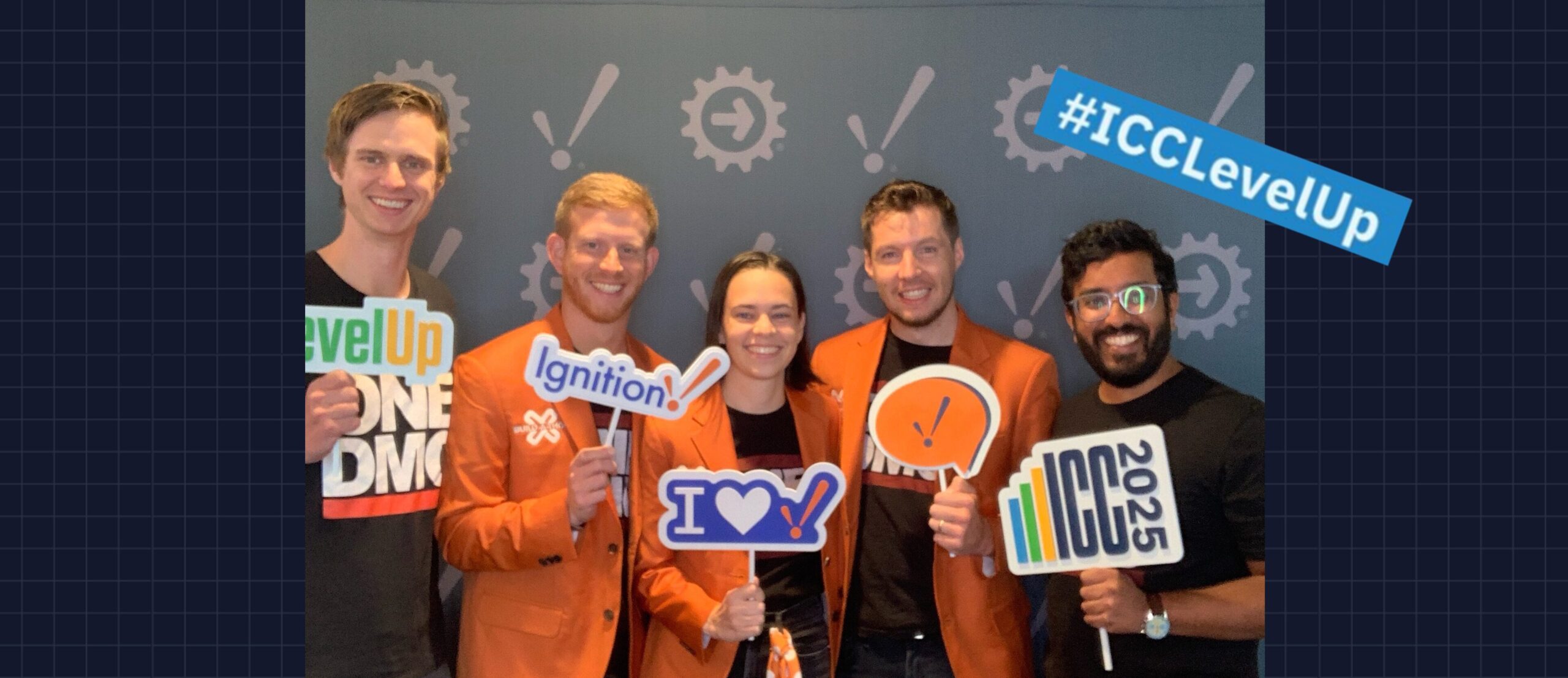

DMC Presents at ICC – Scaling Smart: Architecting for Industrial Growth

-

DMC Quote Board – October 2025

-

Sugar Rush: DMC Denver Runs the Donut Dash 5K

-

Upgrading LabVIEW for Windows 11 Compatibility

-

Celebrating DMC Cincinnati’s First Co-Op Summer