As the popularity of modular instruments grows in R&D development spaces, National Instruments technology, particularly Real-Time and FPGA hardware, is becoming more and more common in volume test, manufacturing, and control applications. As the number of hardware products grows in a given deployment, so too does the task of asset management.

The aim of this discussion is to outline key questions that will be helpful in selecting and asset management solution for projects involving multiple National Instruments targets. I have taken specific focus on Real-Time and FPGA platforms, as they are most commonly deployed in large quantities. Let’s begin with some basic understanding of asset management:

What is asset management?

Asset management is generically described as a system that monitors valuable resources.

In large volume deployments, it is critical to have an understanding of the state of critical components to properly maintain and optimize the uptime of a given system. For example, a common application of asset management technology surrounds fleet vehicles. For a large number of vehicles, say sanitation trucks, a central monitoring system is often used to monitor routes, break downs, and track maintenance schedules which ensure each vehicle is optimized for continuous use.

How does asset management relate to National Instruments?

As larger volume systems are deployed, groupings of PXI controllers, multiple cRIO embedded systems, OEM SBRIO integrated products; it becomes critical to understand the technology available within the LabVIEW platform that describes a given target, and grants the ability to manage it. National Instruments customers are familiar with Measurement and Automation Explorer, which is NI’s approach to asset management in smaller lab settings.

CHALLENGE:

Refresh the Remote Systems sub-section of MAX with 10+ Real Time Targets connected to a network. Configure their IP addresses to place them in a common subnet.

EXTRA CREDIT:

Update each of those targets to run the same version of LabVIEW Real-Time and your custom program.

If you accepted my challenge and were emboldened to complete the extra credit, you will note that this task is tedious, time-consuming, and not optimal for long term support procedures.

What are my options for managing large deployments of NI Real-Time Targets?

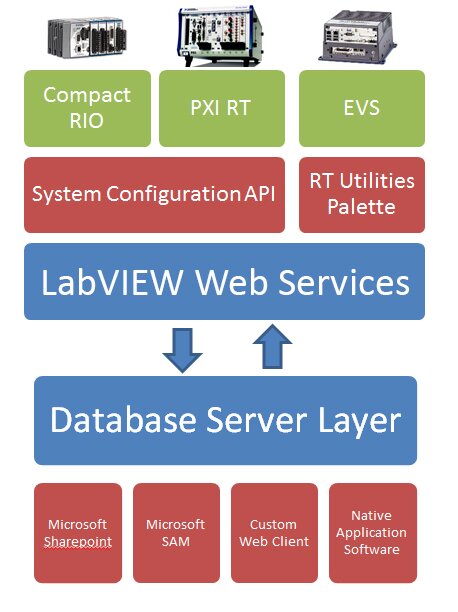

National Instruments released its first response to the question of asset management in 2010. The System Configuration API is a suite of programmatic tools designed to allow access to target information through driver level experts. This API directly exposes the nature of a given targets configuration for consumption by a given application.

Now, to answer your first question, yes this directly leads to custom code development. There is not currently an offering by National Instruments that acts as a robust central monitoring service for Real-Time Targets. However, the System Configuration API can be coupled with the power of LabVIEW Web Services to create a highly scalable framework for asset management.

By utilizing the power of Web Services, native to LabVIEW, the System Configuration API can populate Restful Web Services that provide agnostic connectivity any number of Commercial Off the Shelf (COTS) asset management tools. As NI hardware can now be described in common XML, it may be addressable by any subsystem that can provide/consume Restful Web Methods. Some example technologies include Microsoft SQL Server/Sharepoint, Oracle, and IBM.

How do I calculate my Return on Investment (ROI) for an asset management solution?

As National Instruments does not offer a comprehensive solution for asset management, there is a significant time investment required to implement a scalable and robust infrastructure. Things to always consider at the beginning of development:

- How many systems do I anticipate deploying?

- Will my deployment be locally networked, or globally deployed?

- What is the impact of a single failure? Multiple failures? Fault detection time?

- What is the anticipated maintenance requirement for a deployed system?

- How often might this system require updates during field use?

- What is the cost of continuous field personnel versus remote monitoring application software?

- What type of system security must be maintained?

It’s important to point out that smaller subsystems have a number of options for basic application management. National Instruments systems engineering has produced a reference design for image management on Real-Time targets. The Real Time Application Deployment Utility offers a comprehensive example of how application software can be managed and maintained for multiple targets. This solution, however, does have a number of scaling concerns, especially as network complexity increases.

As deployed systems and embedded targets become common place, National Instruments hardware will require integration with more scalable and maintainable solutions than Measurement and Automation Explorer. The joining of the System Configuration API and native LabVIEW Web Services begins to offer developers and system administrators a pathway to integrating National Instruments hardware into common asset management technologies.

Further Reading

Welcome to the NI System Configuration API

LabVIEW Real-Time Application Deployment (RTAD) Reference Application

Microsoft Software Asset Management

SharePoint Consulting Services

SharePoint Dashboards

Learn more about DMC's LabVIEW programming for real-time and FPGA services.