Don’t you hate it when your coworker inadvertently wires up a 24V PLC to wall power and lets out the magic smoke? Just such a mishap happened in our lab a while back and the broken PLC was sitting around in the junk bin for a while. Figuring there wasn't anything to lose, I decided to try my luck and see if it could be revived.

Fortunately, the Siemens S7-1200 series PLCs are quite easy to disassemble, and I was able to replace the damaged components and restore it to a proper working condition. I definitely wouldn't trust this refurbished PLC to run a critical system, but for testing code in our lab, it should be just fine. I would also recommend reaching out to the manufacturer if you are running into issues with a production PLC, keeping in mind that any warranty may be voided if you attempt to fix it yourself.

Opening the Enclosure

Using a small flat blade screwdriver to push in the side tabs, it's easy to pull the enclosure apart and separate the power conditioning PCB from the main board.

Surveying The Damage

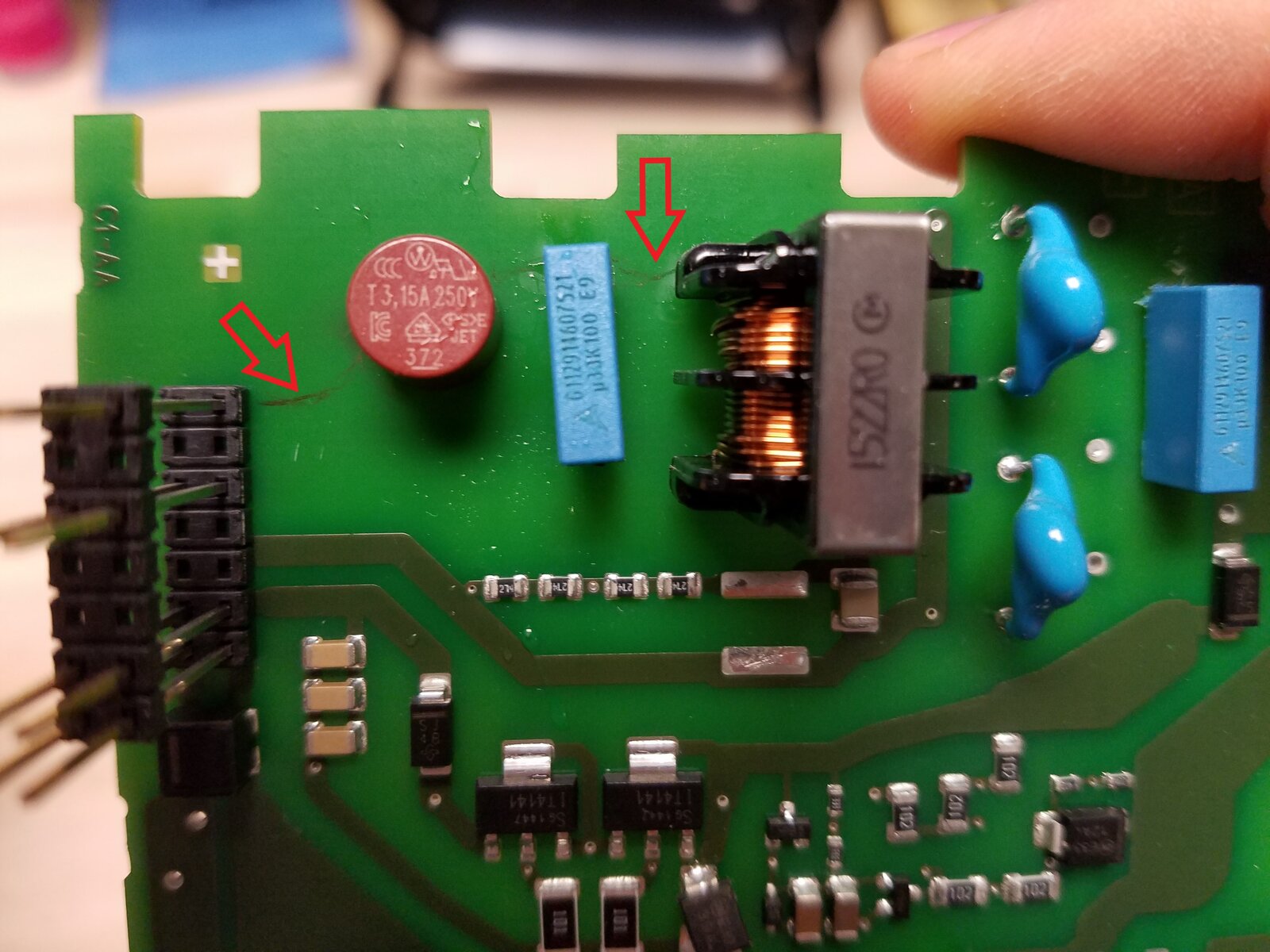

I immediately noticed the burn marks coming from the positive voltage supply pin, but everything else looked okay, and there was no visible damage on the main board.

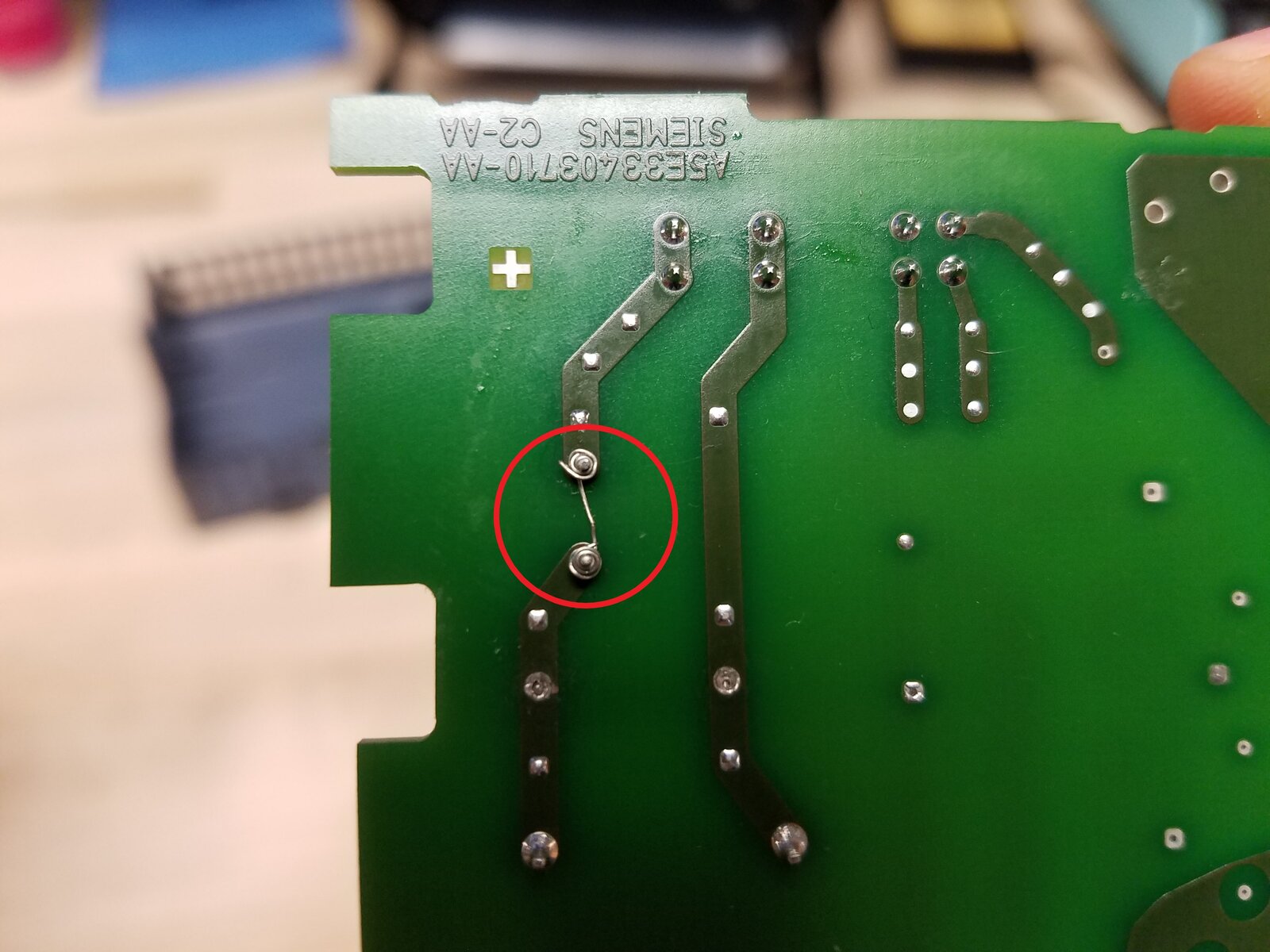

The first component in the circuit is a fuse, designed to limit the damage from precisely this type of mishap. Using a multimeter to check for continuity showed that it was in fact blown, as one would expect. I went ahead and jumpered it out with a wire wrap connection.

Now What?

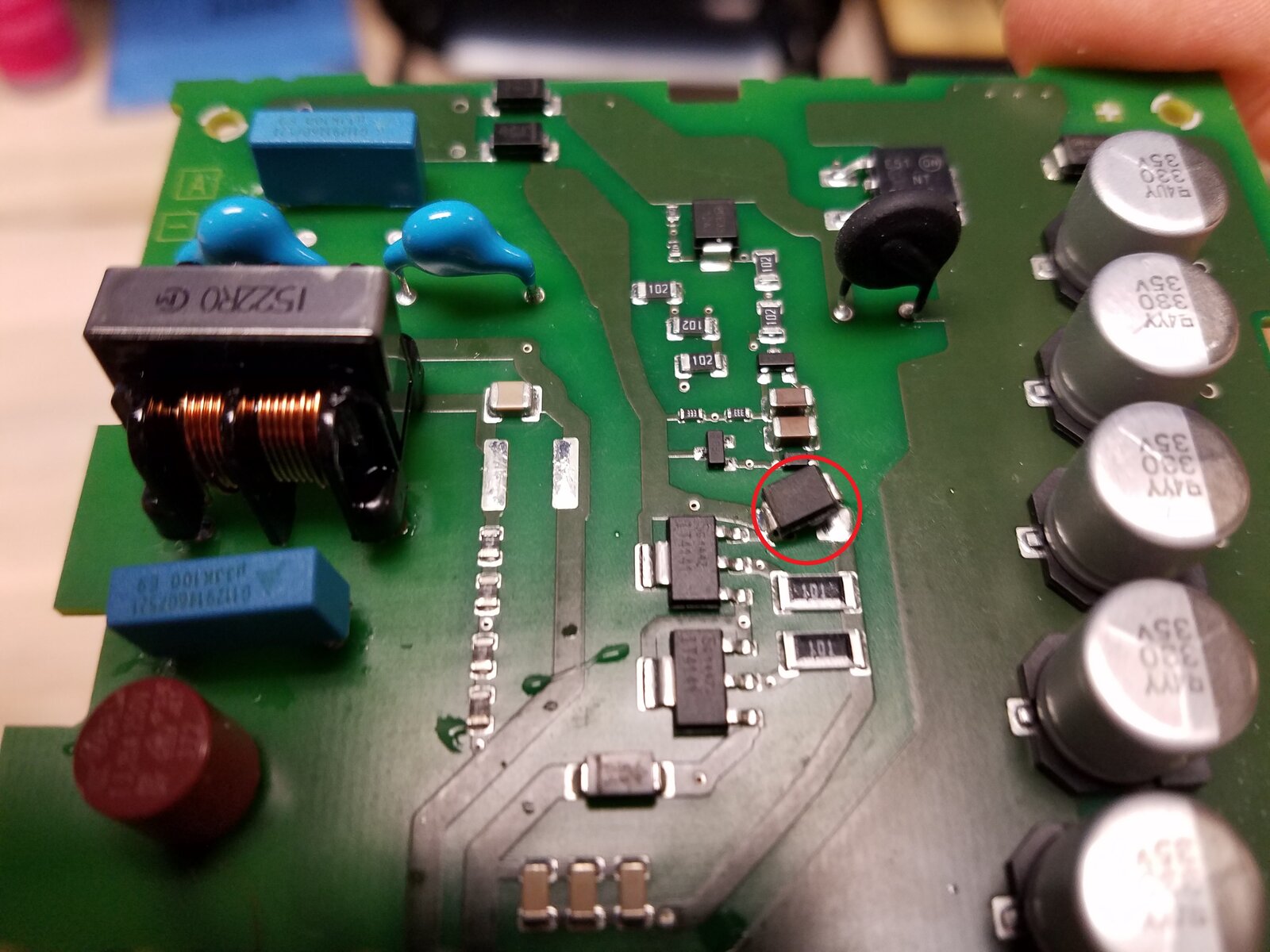

Unfortunately, the fix wasn't going to be that easy. Measuring the resistance across the voltage supply terminals, I found there was now a short circuit. After checking all the components that go across the voltage bus, I found that the culprit was a small Zener diode.

Its purpose is to suppress spikes in the supply voltage, but unsurprisingly, applying 120 VAC far exceeded its maximum power dissipation rating and caused it to short out. Simply desoldering the offending diode from one of its pads fixed the short, and after reassembling the PCBs and applying power, I was surprised that the PLC powered up and was fully functional. Clearly, the protection circuitry had done its job.

Patching Everything Up

Even though I now had a working PLC, leaving it as-is would mean that it would most likely not survive a second jolt of high voltage, so I went ahead and replaced the fuse and Zener diode to make it almost as good as new at a cost of less than $2.

After that, it's easy to snap everything back together, power it up, and watch the blinkenlights turn on!

Conclusion

I hope you enjoyed this sneak peek under the hood of a device that we work with on a daily basis. It was nice to see that Siemens designs their PLCs to be pretty robust and easy to disassemble, unlike the typical consumer electronics devices you tend to see these days. Share your own stories of hacking PLC hardware in the comments section below!

Learn more about DMC's Siemens S7 PLC programming expertise and embedded design expertise.